Quantitative test method for components of additives in PA6 producing process

A technology of production process and testing method, applied in the field of nylon chemical fiber, can solve the problems such as the inability to measure and control the blending effect and concentration, the inability of the additive solution to pass, and the detection, etc., to achieve low cost, good reproducibility and fast analysis speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

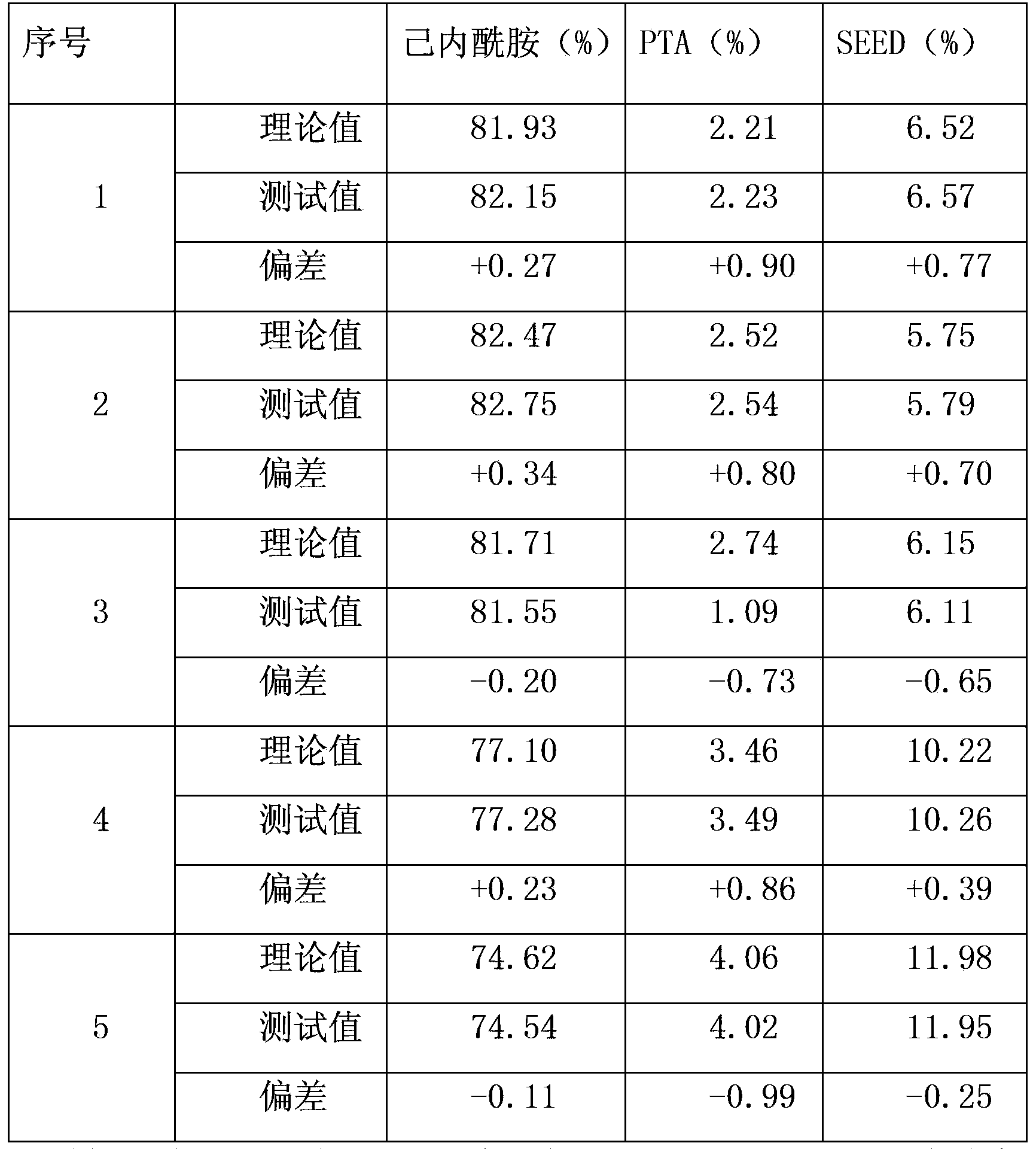

Examples

Embodiment Construction

[0018] The present invention will be further described below according to specific embodiments.

[0019] Near-infrared light refers to electromagnetic waves with wavelengths in the range of 780-2500nm, which is the earliest non-visible light region known to people. Modern near-infrared spectroscopy is the fastest-growing and most eye-catching spectroscopic analysis technique since the 1990s. It is an organic combination of spectroscopic measurement technology and chemometrics, and is known as the giant of analysis. Near-infrared spectroscopy analysis technology includes qualitative analysis and quantitative analysis. The purpose of qualitative analysis is to determine the composition and structure of substances, while quantitative analysis is to determine the content of certain components in substances or the value of quality attributes of substances. Different from the commonly used chemical analysis methods, near-infrared spectroscopy is an indirect analysis technique, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com