Mixed water pretreatment method for sintering production

A technology of mixing water and pretreatment, which is applied in the field of water treatment and can solve problems such as mixing, uneven wetting, and poor results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for pretreatment of mixed water for sintering production, comprising the following steps,

[0034] 1. The water is magnetized through the catalytic magnetic water processor 100 to form magnetized water; the catalytic magnetic water processor 100 is installed on the water supply pipeline, and the flow rate in the water supply pipeline is 0-35m 3 / h, magnetic flux intensity 6000GS, temperature 0-80°C.

[0035] 2. Mix and add MBC-Z type functional additive in magnetized water, the MBC-Z type functional additive is an aqueous solution, and its concentration is controlled between 45%; the MBC-Z type functional additive is in the In the state of stirring in the stirring tank 300, it is injected into the magnetized mixed water pipeline through the high-pressure delivery pump 400, and the high-pressure injection flow rate is controlled at 0.5L-1.5L / min.

[0036] 3. The mixed water is sprayed into the sintered mixture in the primary mixer 200 .

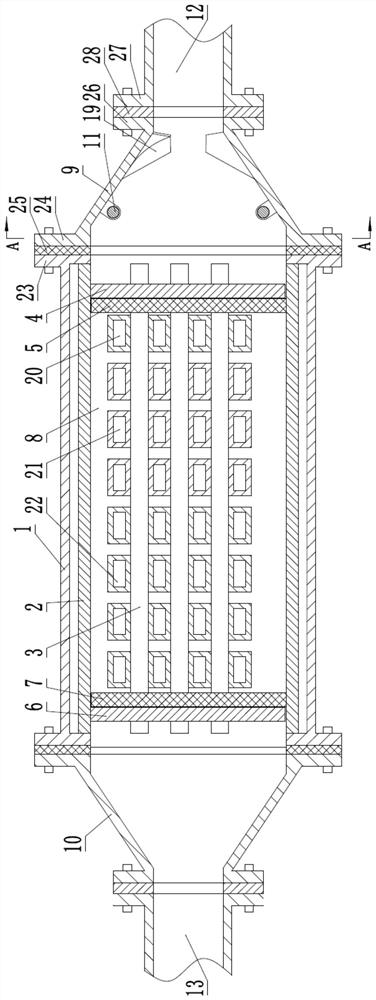

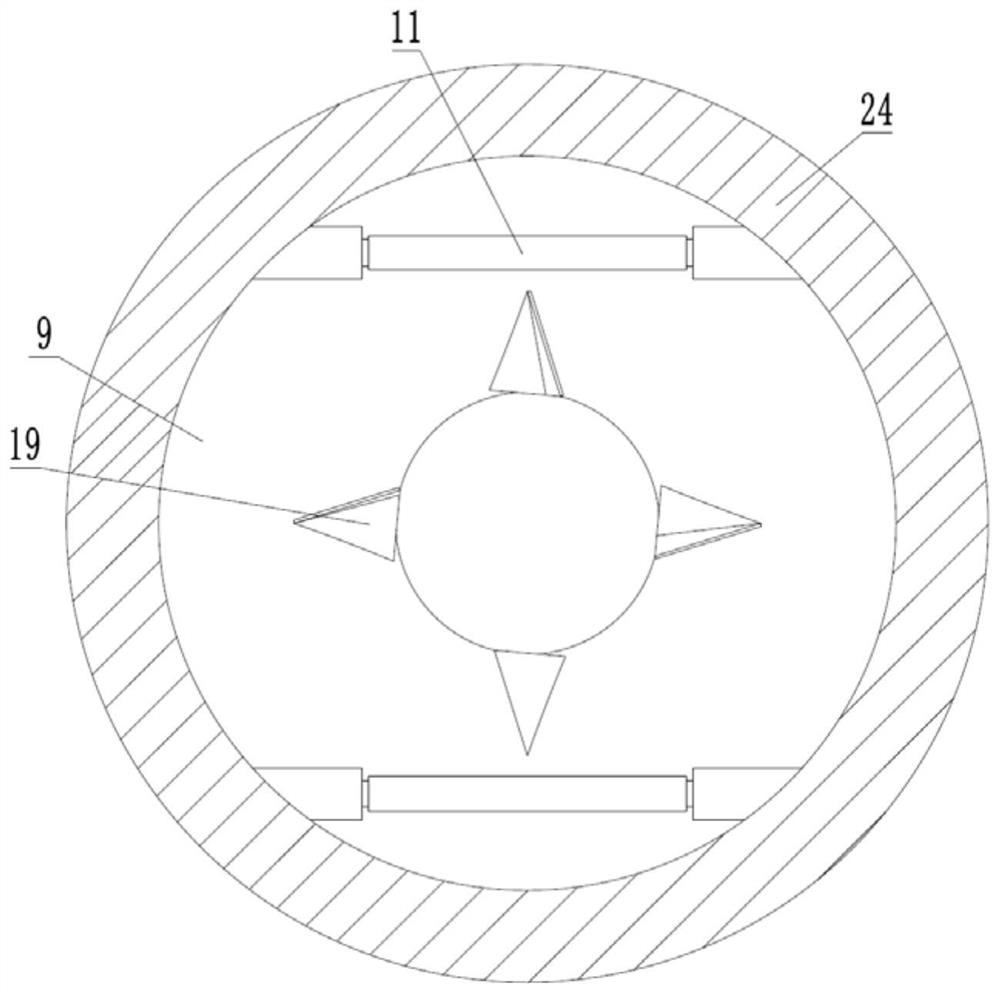

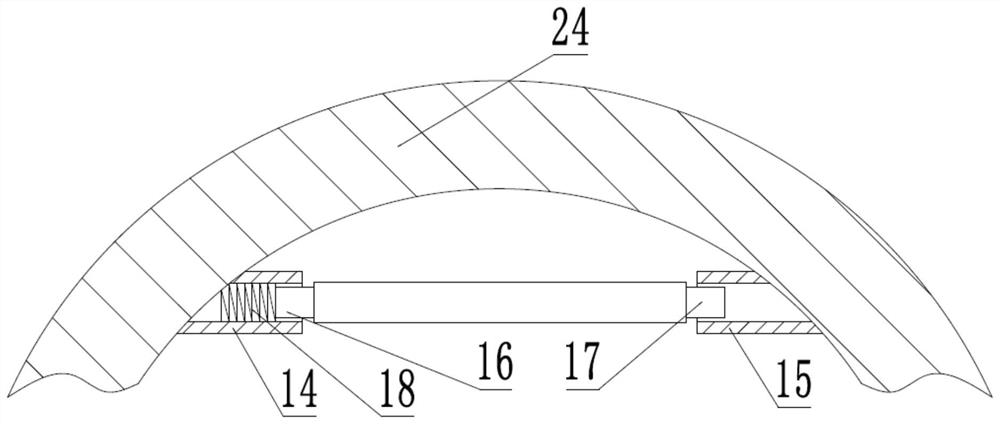

[0037] Among them, th...

Embodiment 2

[0039] A method for pretreatment of mixed water for sintering production, comprising the following steps,

[0040] 1. The water is magnetized through a catalytic magnetic water processor to form magnetized water; a magnetizer is installed on the water supply pipeline, and the flow rate in the water supply pipeline is 0-35m 3 / h, magnetic flux intensity 6000GS, temperature 0-80°C.

[0041] 2. Mix and add MBC-Z type functional additive in the magnetized water, the MBC-Z type functional additive is an aqueous solution, and its concentration is controlled between 50%; the MBC-Z type functional additive is in the In the state of stirring in the stirring tank, it is injected into the magnetized mixed water pipeline through the high-pressure delivery pump, and the high-pressure injection flow rate is controlled at 0.5L-1.5L / min.

[0042] 3. Spray the mixed water into the sintered mixture in the primary mixer.

[0043] Among them, the specific formula of the MBC-Z functional additive ...

Embodiment 3

[0046] A method for pretreatment of mixed water for sintering production, comprising the following steps,

[0047] 1. The water is magnetized through a catalytic magnetic water processor to form magnetized water; a magnetizer is installed on the water supply pipeline, and the flow rate in the water supply pipeline is 0-35m 3 / h, magnetic flux intensity 6000GS, temperature 0-80°C.

[0048] 2. Mix and add MBC-Z type functional additive in magnetized water, the MBC-Z type functional additive is an aqueous solution, and its concentration is controlled between 30%; the MBC-Z type functional additive is in the In the state of stirring in the stirring tank, it is injected into the magnetized mixed water pipeline through the high-pressure delivery pump, and the high-pressure injection flow rate is controlled at 0.5L-1.5L / min.

[0049] 3. Spray the mixed water into the sintered mixture in the primary mixer.

[0050] Among them, the specific formula of the MBC-Z functional additive is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com