Spinning procedure process technological parameter optimization method based on carbon accounting

A technology for process parameter optimization and process parameter application in the field of optimization, which can solve very few problems and achieve the effect of reducing carbon emissions and production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

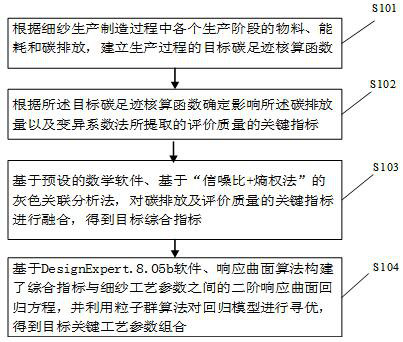

Method used

Image

Examples

Embodiment

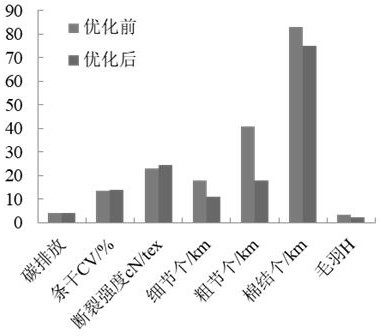

[0098] Selection of spinning process parameters and quality evaluation indicators:

[0099] The drafting, twisting and winding devices involved in the spinning process are the main devices that generate high energy consumption. Among them, the size of the spindle speed affects the structure and performance of the spun yarn, and restricts the friction between the spun yarn, the traveler and the air; the configuration of the draft ratio in the rear area directly affects the evenness of the spun yarn. If the draft ratio in the rear area is too small, it is easy to The drafting of the spun yarn will not be opened, and if it is too large, it will easily cause the distribution structure of the spun yarn to deteriorate. Therefore, a reasonable configuration of the draft multiple in the rear area to enhance its stability can effectively improve the fluctuation of the yarn quality; the size of the twist coefficient directly affects The yarn forming performance affects the subsequent pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com