Polyester drawn textured yarn process optimization method

A polyester low elastic yarn, process optimization technology, applied in design optimization/simulation, instrumentation, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

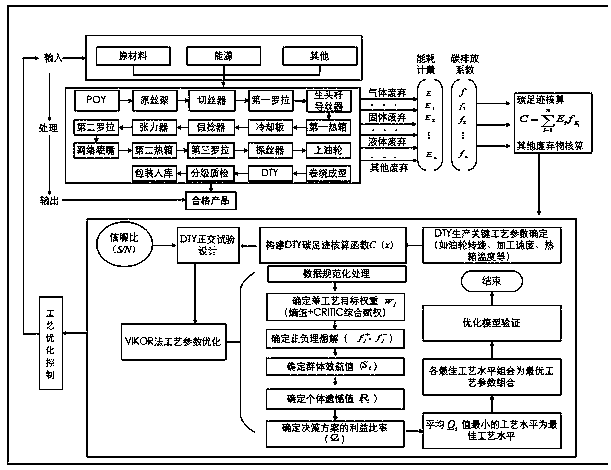

Method used

Image

Examples

experiment example

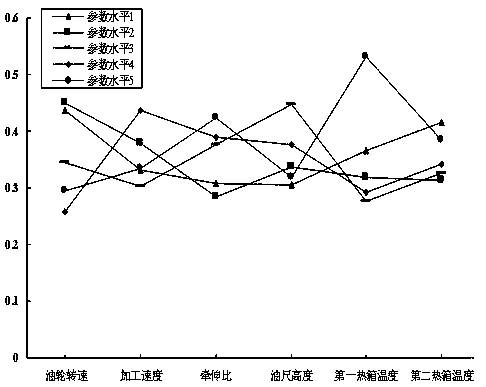

[0159] 3.2 Orthogonal test factor determination

[0160] On the basis of step S103A, select the tanker speed from the production process parameters ( ), processing speed ( ), draft ratio ( ), dipstick height ( ), the first hot box temperature ( ) and the second hot box temperature ( ) is used as the test optimization index, and other parameters are set as standard values; to reflect the polyester low stretch yarn ( DTY ) breaking strength of finished product quality ( ), elongation at break ( ), crimp shrinkage ( ), boiling water shrinkage ( ), curl stability ( ) and carbon emissions ( ) as a comprehensive process optimization goal, an orthogonal experiment with 6 factors and 5 levels was designed , see Table 1 for specific parameter settings.

[0161] Table 1 Orthogonal test design scheme table

[0162]

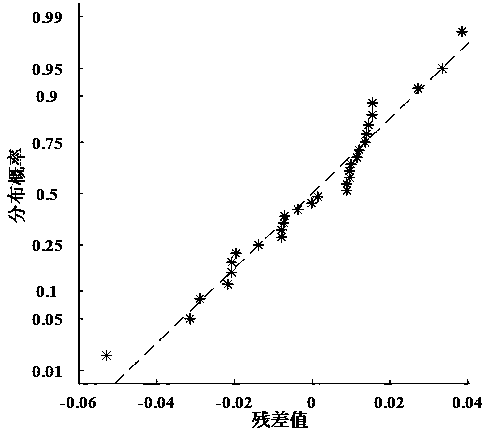

[0163] According to the test factors and levels in Table 1, 25 sets of tests were designed through the orthogonal table to obtain the polyester ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com