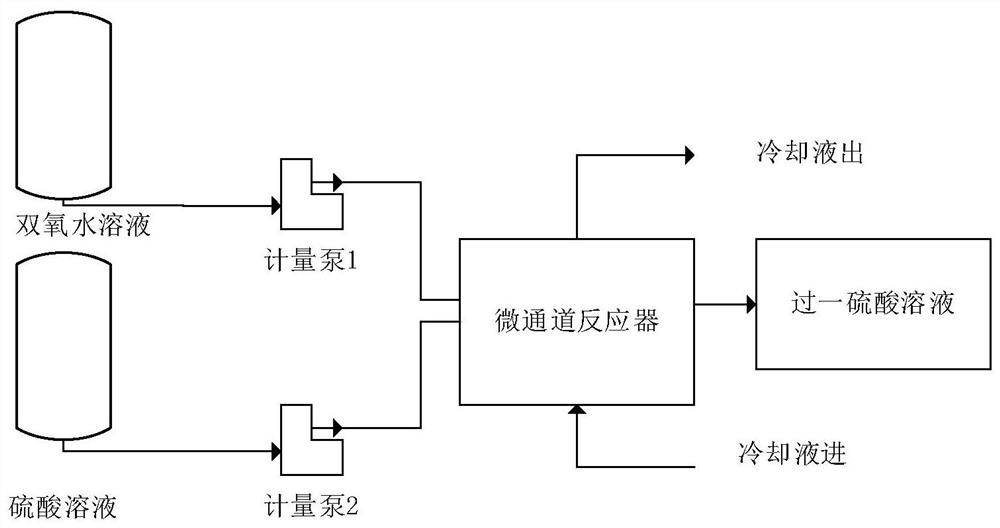

Method for continuously preparing peroxymonosulfuric acid by using microchannel reactor

A microchannel reactor, microchannel technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, etc., Achieve the effect of improving yield, less loss of active material and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

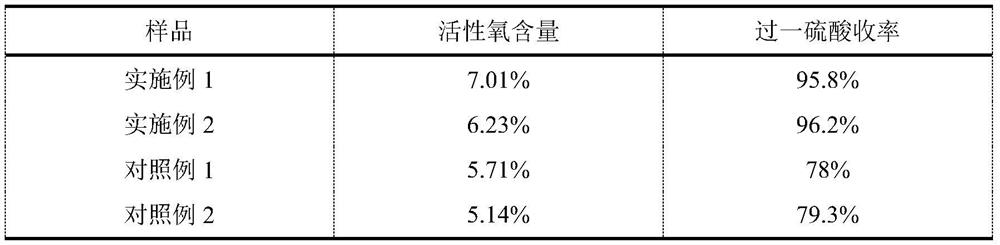

Embodiment 1

[0030] The hydrogen peroxide with a mass fraction of 70% and the sulfuric acid with a mass fraction of 98% were transported into the microchannel reactor at the same time according to the molar ratio of 1:1.7. The temperature of the reaction solution was controlled at 15°C and the reaction residence time was 2 minutes. Two sets of reaction modules were used. The liquid holding capacity of each group of reaction modules is 150mL, and the characteristic dimension of the microchannel is 0.4mm, and a persulfuric acid solution is prepared. The measured active oxygen content in the peroxymonosulfuric acid solution is 7.01%, and the yield of peroxymonosulfuric acid is 95.8% (the yield is based on hydrogen peroxide).

Embodiment 2

[0032] The hydrogen peroxide with a mass fraction of 50% and the sulfuric acid with a mass fraction of 115% are transported into the microchannel reactor at the same time according to the molar ratio of 1:2.1 respectively. The temperature of the reaction solution is controlled at 25°C and the reaction residence time is 3 minutes. Three sets of reaction modules are used. , the liquid holding capacity of each group of reaction modules is 300mL, the characteristic scale of the microchannel is 0.4mm, and a solution containing peroxymonosulfuric acid is prepared. The measured active oxygen content in the peroxymonosulfuric acid solution is 6.23%, and the yield of peroxymonosulfuric acid is 96.2% (the yield is based on hydrogen peroxide).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com