Method and device for position and posture monitoring of rocker arms of coal mining machine on basis of fiber grating

A technology of fiber grating and fiber grating demodulation, which is applied in the field of monitoring the position and posture of the rocker arm of the coal mining machine, and the field of the position and posture monitoring device of the rocker arm of the coal mining machine based on the fiber grating, which can solve the problem of the ineffective monitoring of the position and posture of the rocker arm of the coal mining machine. Ideal, low reliability of recognition results, unstable signal acquisition and other problems, to achieve the effect of strong anti-electromagnetic interference ability, high reliability, and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

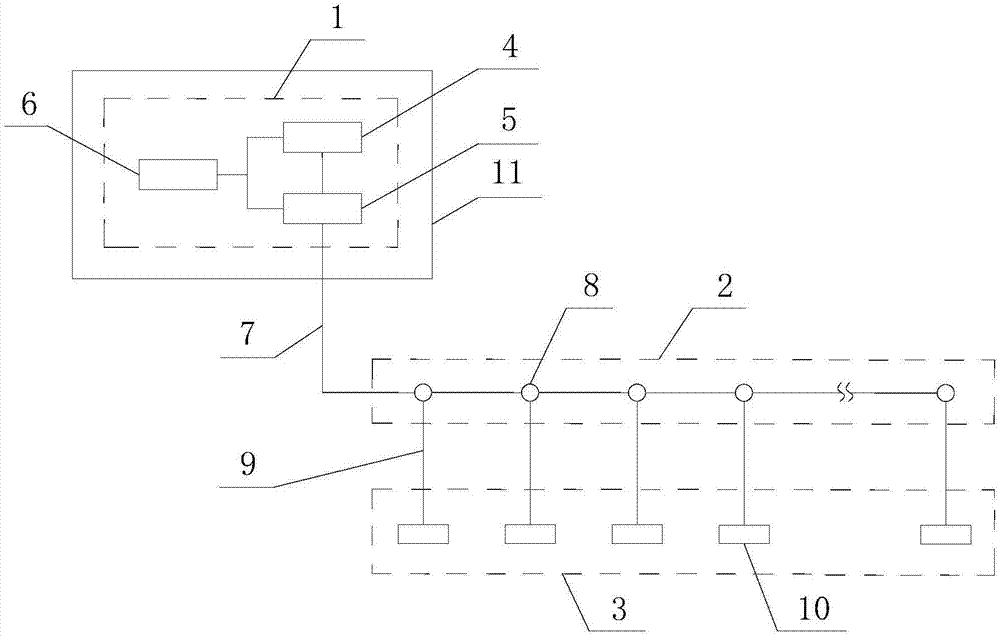

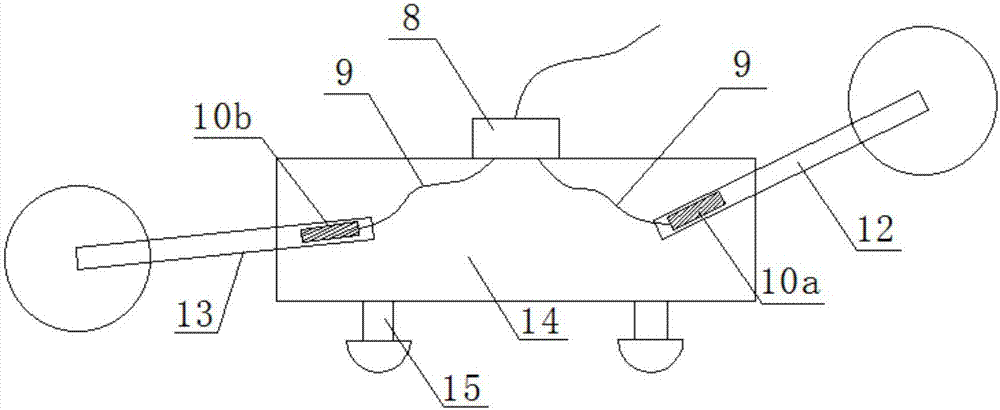

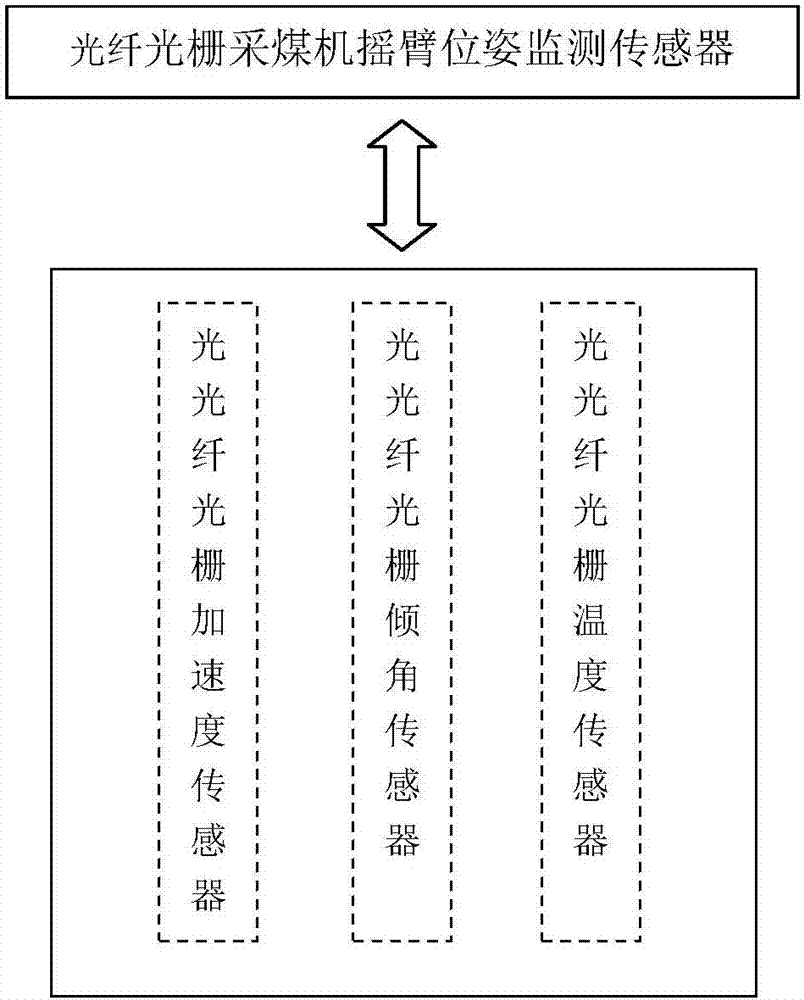

[0041]When the piston rod 12 of the front rocker arm hydraulic cylinder of the coal mining machine and the piston rod 13 of the rear rocker arm hydraulic oil cylinder are changed, the internal grating pitch of the fiber grating shearer rocker arm position monitoring sensor 10 is changed, thereby The central wavelength of the optical signal reflected by the grating drifts; the pose data transmission subsystem is composed of a mine-used transmission optical fiber 7, an optical fiber junction box 8 and an optical fiber pigtail 9, and the fiber grating shearer rocker arm pose monitoring The sensor 10 transmits the reflected optical signal to the mine transmission fiber 7 through its own fiber pigtail 9, and the fiber pigtail 9 is connected to the mine transmission fiber 7 through an optical fiber junction box 8; the data analysis subsystem is installed on the ground In the monitoring room, the data analysis subsystem consists of a monitoring computer 4, a fiber grating demodulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com