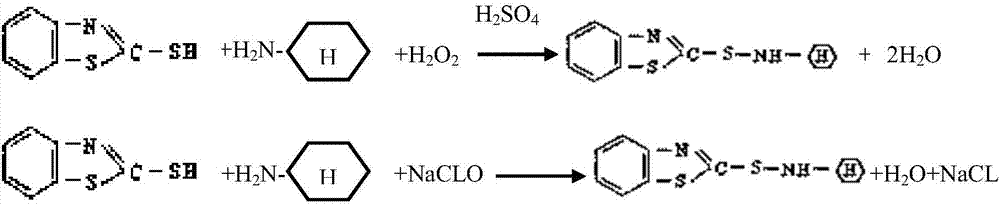

Method for using rubber accelerator M to synthesize sulfonamide accelerator CBS by solvent purification method

A technology of rubber accelerator and sulfenamides, which is applied in the field of solvent purification rubber accelerator M to synthesize sulfenamide accelerator CBS, to achieve the effect of reducing dried sludge, reducing CODcr, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

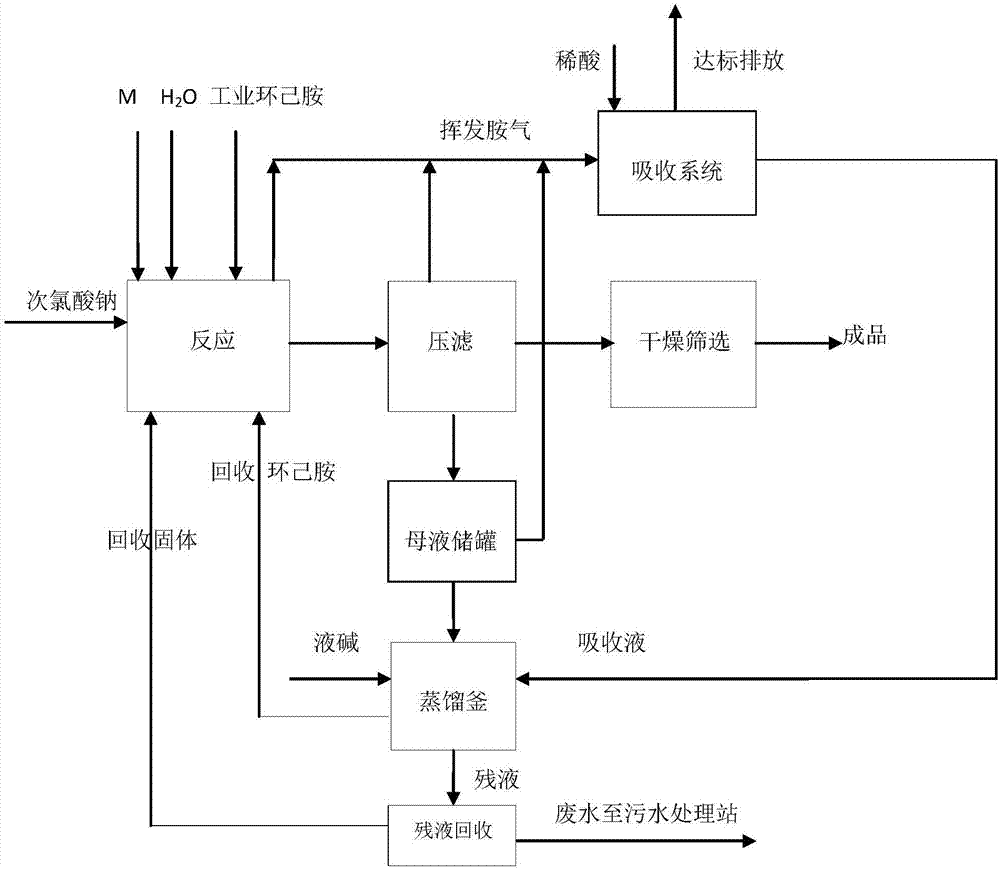

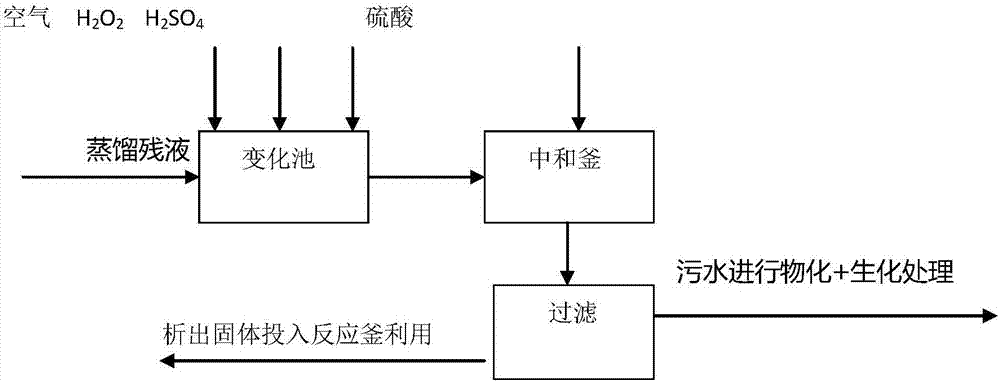

Method used

Image

Examples

Embodiment

[0028] 1. Determine the best production process conditions through the following experiments:

[0029] (1) The influence of raw material ratio on product quality and yield

[0030] When the reaction temperature is controlled at 35-40°C and the reaction time is 2.0-3.0 hours, the influence of the experimental raw material ratio on product quality and yield:

[0031]

[0032] Note: The dual oxidant system is used, and the amount of sodium hypochlorite used is subject to the end point detection.

[0033] According to experimental data analysis, when M and cyclohexylamine are in molar ratio of 1:1.8, the product appearance is light yellow, and yield, fusing point are all on the low side, along with the reduction of M and cyclohexylamine mol ratio, appearance, yield, The melting point is all improved, when there is too much cyclohexylamine, because the product is dissolved in the cyclohexylamine solution, the yield is reduced, and the post-treatment recovery of cyclohexylamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com