Method for preparing alternate layered biodegradable polymer barrier material with excellent water vapor and oxygen barrier properties

A water vapor barrier, biodegradable technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., to achieve the effects of improved diffusion paths, good humidity stability, and good water vapor and oxygen barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

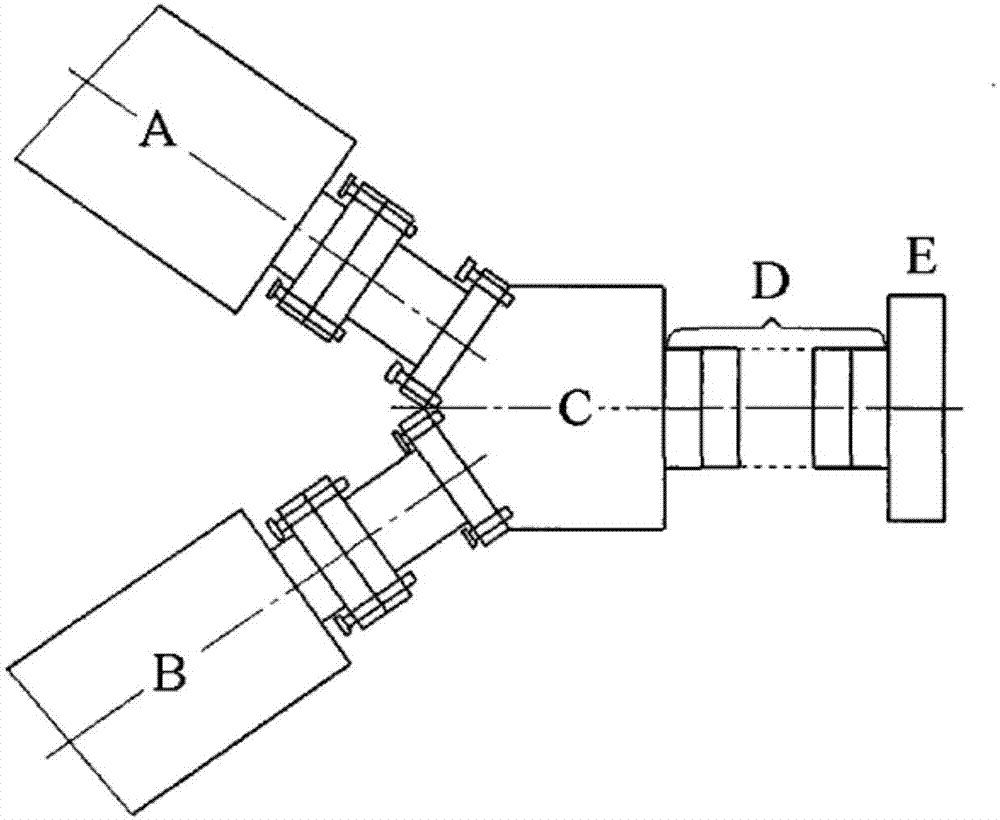

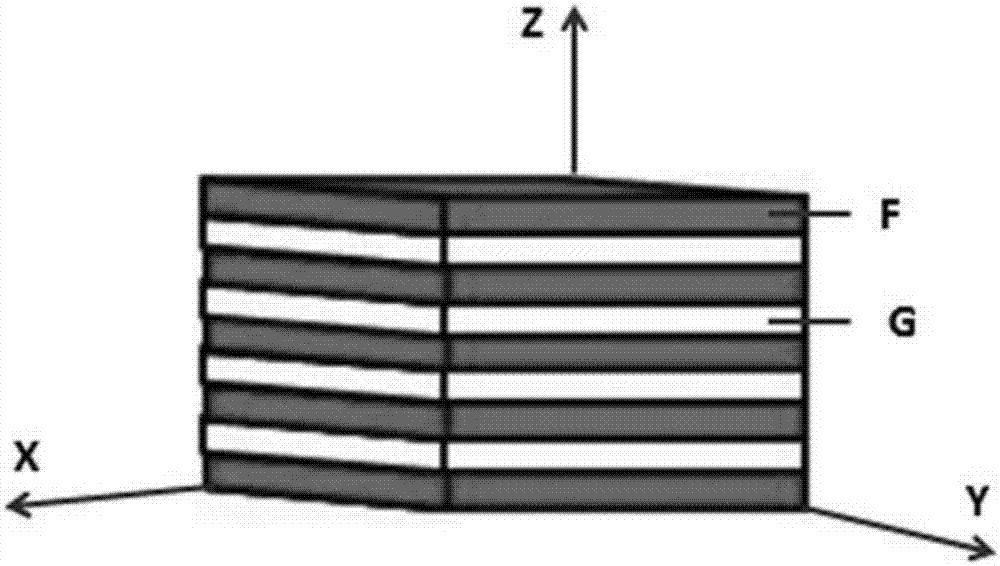

Method used

Image

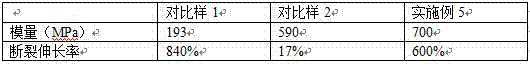

Examples

Embodiment 1

[0047] In the first step, the biodegradable polymer-based water vapor barrier layer (hereinafter referred to as the water vapor barrier layer) selects polycaprolactone as the matrix of the water vapor barrier layer, and glyceryl tristearate as the dispersed phase of the water vapor barrier layer; The molecular-based oxygen barrier layer (hereinafter referred to as the oxygen barrier layer) uses polyvinyl alcohol as the matrix of the oxygen barrier layer, and montmorillonite as the filler of the oxygen barrier layer, and prepares materials according to the following components and parts by weight:

[0048] Water vapor barrier layer components parts by weight

[0049] Polycaprolactone (for water vapor barrier matrix) 80

[0050] Glyceryl tristearate (for the dispersed phase of the water vapor barrier layer) 20

[0051] Oxygen barrier layer components parts by weight

[0052] Polyvinyl alcohol (for oxygen barrier layer matrix) 90

[0053] Montmorillonite (filler for oxygen bar...

Embodiment 2

[0069] In the first step, the biodegradable polymer-based water vapor barrier layer (hereinafter referred to as the water vapor barrier layer) selects polycaprolactone as the matrix of the water vapor barrier layer, and glyceryl tristearate as the dispersed phase of the water vapor barrier layer; The molecular-based oxygen barrier layer (hereinafter referred to as the oxygen barrier layer) uses polyvinyl alcohol as the oxygen barrier layer matrix, and montmorillonite as the oxygen barrier layer filler, and prepares materials according to the following components and parts by weight:

[0070] Water vapor barrier layer components parts by weight

[0071] Polycaprolactone (for water vapor barrier matrix) 70

[0072] Glyceryl tristearate (for the dispersed phase of the water vapor barrier layer) 30

[0073] Oxygen barrier layer components parts by weight

[0074] Polyvinyl alcohol (for oxygen barrier layer matrix) 85

[0075] Montmorillonite (filler for oxygen barrier layer) 15...

Embodiment 3

[0091] In the first step, the biodegradable polymer-based water vapor barrier layer (hereinafter referred to as the water vapor barrier layer) uses polycaprolactone as the water vapor barrier layer matrix, and trimyristin as the dispersed phase of the water vapor barrier layer; the biodegradable high The molecular-based oxygen barrier layer (hereinafter referred to as the oxygen barrier layer) uses polyvinyl alcohol as the matrix of the oxygen barrier layer, and montmorillonite as the filler of the oxygen barrier layer, and prepares materials according to the following components and parts by weight:

[0092] Water vapor barrier layer components parts by weight

[0093] Polycaprolactone (for water vapor barrier matrix) 80

[0094] Trimyristin (for the dispersed phase of the water vapor barrier layer) 20

[0095] Oxygen barrier layer components parts by weight

[0096] Polyvinyl alcohol (for oxygen barrier layer matrix) 85

[0097] Montmorillonite (filler for oxygen barrier ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com