Environment-friendly non-woven wallpaper body paper and method for producing same

A production method and wallpaper technology, applied in pulp beating/refining method, textiles and papermaking, paper, etc., can solve problems such as environmental pollution, poor surface performance, easy lint and powder loss, etc., to reduce environmental pollution and stabilize paper type , good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

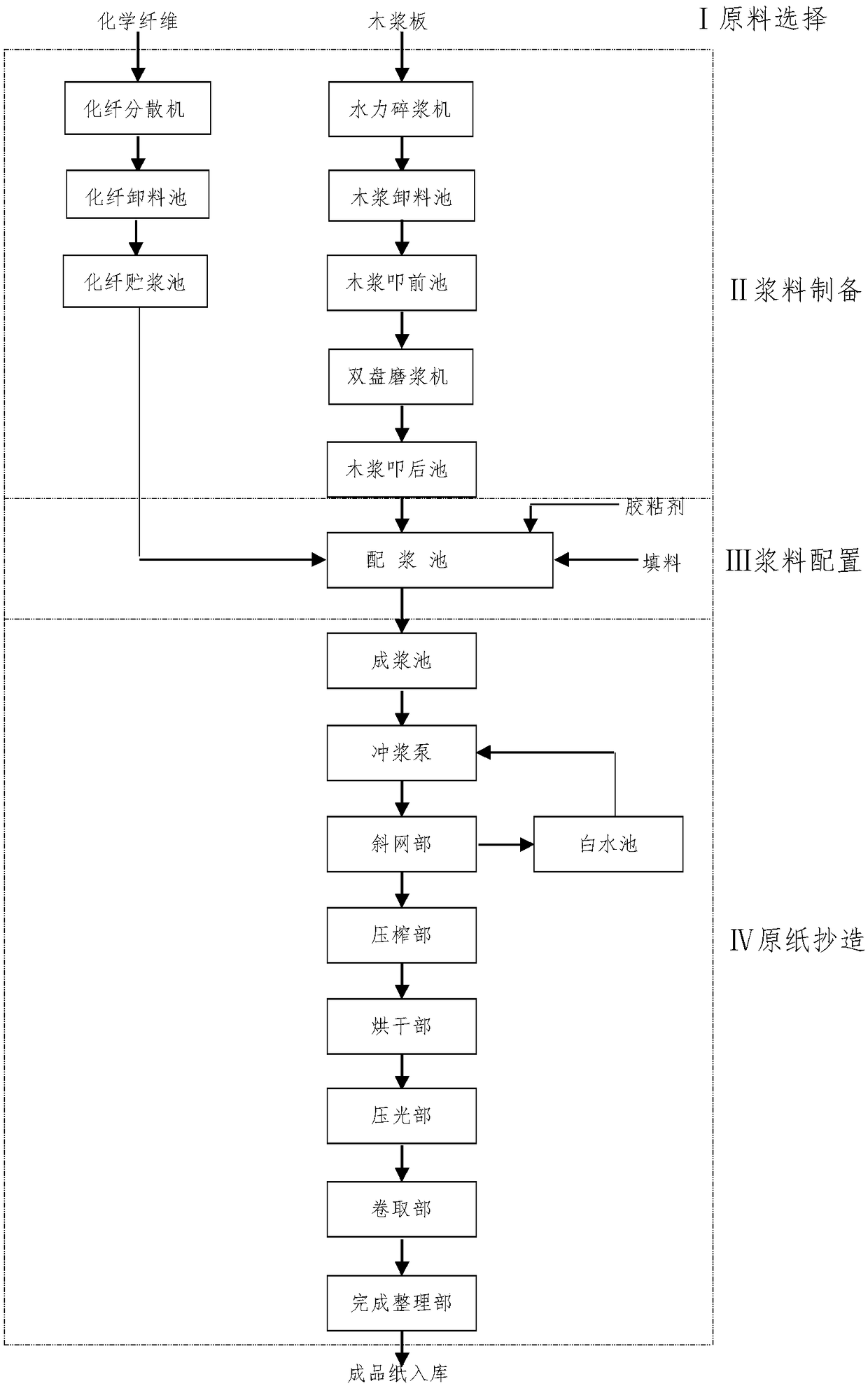

[0021] like figure 1 As shown, the production method of environmentally friendly non-woven wallpaper base paper includes four steps: raw material selection, slurry preparation, slurry configuration, and base paper making. First, select coniferous wood pulp boards and hardwood pulp boards, as well as polyester fibers with good chemical stability and elasticity in chemical fibers, and then proceed to the slurry preparation process: among them, the coniferous wood pulp boards and hardwood pulp boards are each 50% , crushed by a hydraulic pulper, the crushing concentration is 3% to 5%, the crushing time is 10min to 15min, and the crushing temperature is 40°C to 50°C; the crushed pulp enters the wood pulp discharge tank, and then enters the wood pulp After the pulp is tapped in the front tank, it is refined by a double-disc refiner, and the knocking degree reaches 30°SR~35°SR. -3 mol / L sodium dodecylbenzene sulfonate washing to remove surface grease, hot water washing temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com