Method for preparing polymer/inorganic filler composite material

A technology of inorganic fillers and composite materials, which is applied in the field of preparation of polymer/inorganic filler composite materials, can solve the problems of complex process and increased cost, and achieve the effects of simple process, reduction of defects, and improvement of dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

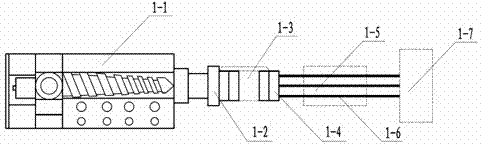

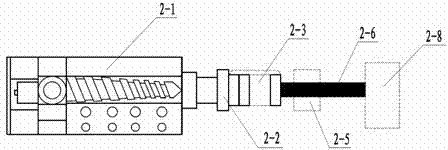

Method used

Image

Examples

Embodiment 1

[0057] A raw material of polyethylene / inorganic filler composite material comprises the following components and their contents in parts by weight:

[0058] components weight ratio Polyethylene (PE, as a crystalline polymer matrix) 95 Talc (Talc, a layered silicate filler) 5

[0059] Note: The above components do not contain compatibilizers.

[0060] The first step, at first prepare raw materials by above-mentioned components;

[0061] In the second step, first place the talc powder (Talc) in an oven at 120°C for 12 hours;

[0062] In the third step, the dry talcum powder and polyethylene obtained in the second step are placed in a high-mixer and pre-mixed for 6 minutes at a speed of 150 revolutions per minute; to obtain a polyethylene / talcum powder premix;

[0063] Then, put the obtained polyethylene / talcum powder premix into a twin-screw extruder for melt blending, extruding and granulating to obtain polyethylene / talcum powder premixed composite...

Embodiment 2

[0068] A raw material of polyethylene / inorganic filler composite material comprises the following components and their contents in parts by weight:

[0069] components weight ratio Polyethylene (PE, as a crystalline polymer matrix) 30 Talc (Talc, a layered silicate filler) 40 Polyethylene grafted maleic anhydride (PE-MA, as compatibilizer) 30

[0070] The first step, at first prepare raw materials by above-mentioned components;

[0071] In the second step, first place the talc powder (Talc) in a 120°C oven for 12 hours, and put the compatibilizer polyethylene grafted maleic anhydride in an 80°C oven for 12 hours;

[0072] In the third step, the polyethylene, dry talcum powder and compatibilizer obtained in the second step are placed in a high mixer and pre-mixed for 5 minutes at a speed of 100 rpm to obtain polyethylene / talcum powder / polyethylene bonded branched maleic anhydride premix;

[0073] Then, put the obtained polyethylene / talcum pow...

Embodiment 3

[0078] A kind of raw material of polypropylene / inorganic filler composite material comprises following component and its weight portion content:

[0079] components weight ratio Isotactic polypropylene (PP, as a crystalline polymer matrix) 70 Graphite (NG, for inorganic filler) 30

[0080] Note: The above components do not contain compatibilizers.

[0081] The first step, at first prepare raw materials by above-mentioned components;

[0082] In the second step, first place the inorganic filler graphite (NG) in an oven at 80°C for 12 hours;

[0083] In the third step, the isotactic polypropylene obtained in the second step and the dry graphite are placed together in a high-mixer and premixed for 5 minutes, and its rotating speed is 100 rpm to obtain an isotactic polypropylene / graphite premix;

[0084] Then, put the obtained premix into a twin-screw extruder for melt blending, extrusion, and granulation to obtain isotactic polypropylene / graphite pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com