Continuous producing technology and device for thermal insulation dry powder mortar

A technology of dry powder mortar and production process, which is applied to clay preparation equipment, clay mixing equipment, and sales raw material supply equipment, etc., which can solve problems such as high productivity, segregation differences, and poor product uniformity, and achieve high production efficiency and low labor intensity. , the effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

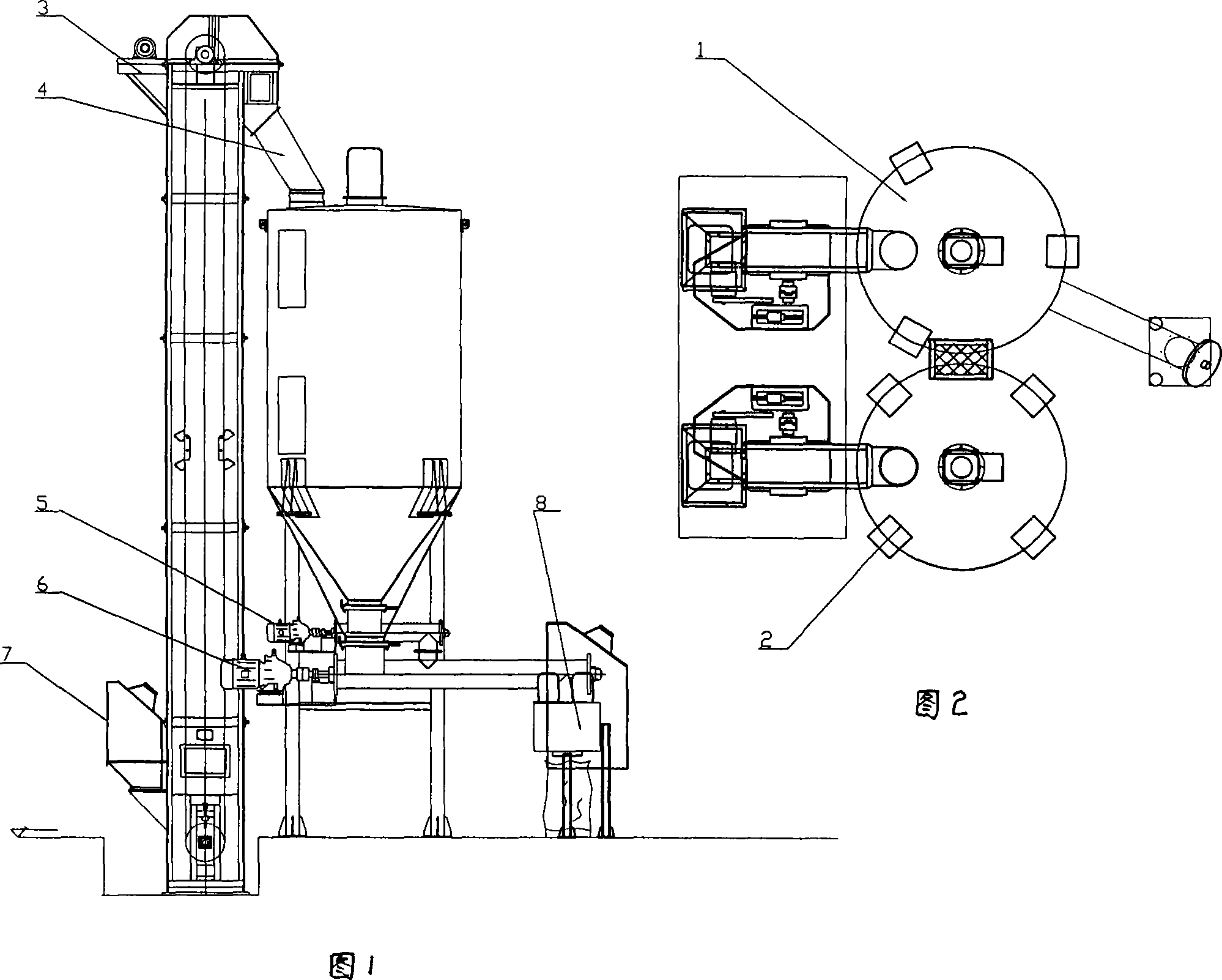

[0021] With reference to accompanying drawing, the present invention is described in detail:

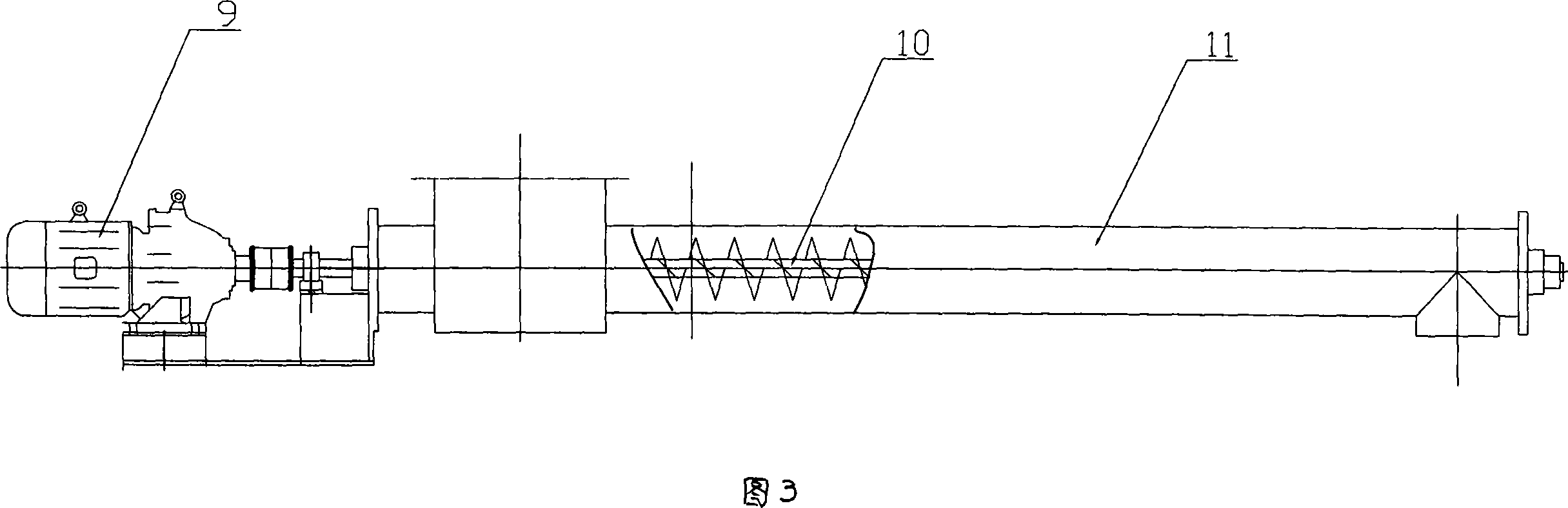

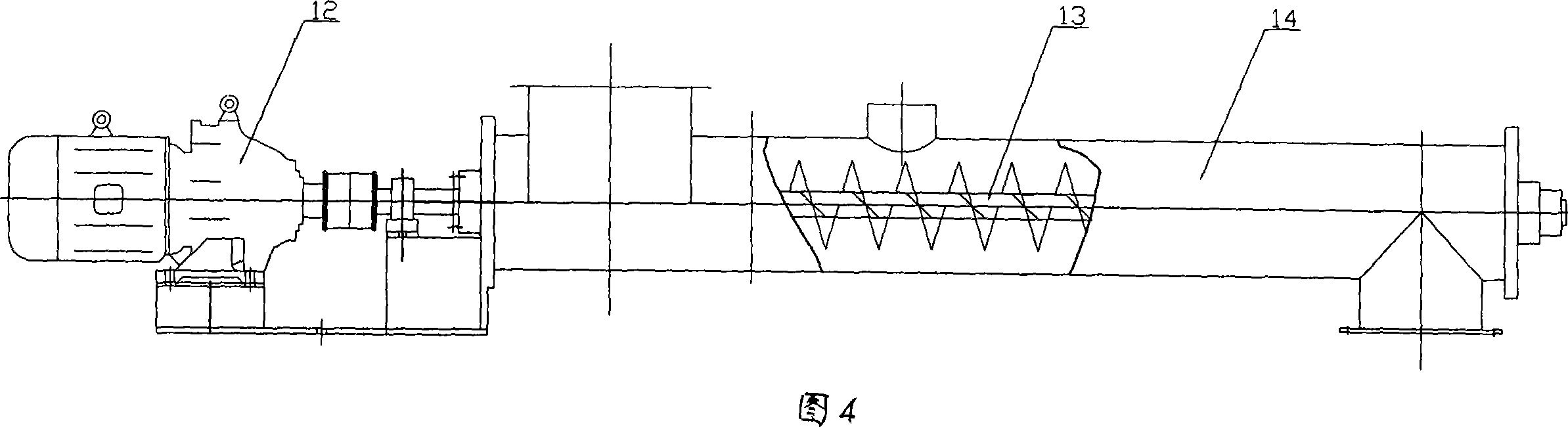

[0022] Feed the uniformly mixed powder material from the hopper 7, and enter the silo 1 through the bucket elevator 3 through the chute 4; and feed the inorganic lightweight aggregate from another hopper, through the other bucket elevator through the chute Enter bin 2. The material in the silo 1 enters the feeder 5, and enters the mixer 6 uniformly from the housing 11 at a set speed; the material in the silo 2 enters the feeding section at the left end of the feeding mixer 6, and the material flows from the The housing 14 enters evenly at a set speed and mixes with the powder from the feeder 5, and the mixed material is bagged and packaged into a product by the packaging machine 8. The whole working process is continuous quantitative batching, mixing and packaging.

[0023] Product quality parameter comparison:

[0024] Performance name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com