A kind of preparation method of aluminum-tantalum alloy

A tantalum alloy and alloy technology, which is applied in the field of master alloy preparation, can solve the problems of titanium alloy quality influence, poor alloy uniformity, etc., and achieve the effects of convenient production and operation, easy storage and transportation, and easy preparation.

Active Publication Date: 2016-05-04

CHENGDE TIANDA VANADIUM IND

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method has the advantages of simple equipment, convenient operation, and less investment. The disadvantage is that the uniformity of the alloy is poor, and impurities, especially gas phase impurities such as oxygen and nitrogen, cannot be controlled, which directly affects the quality of titanium alloys.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

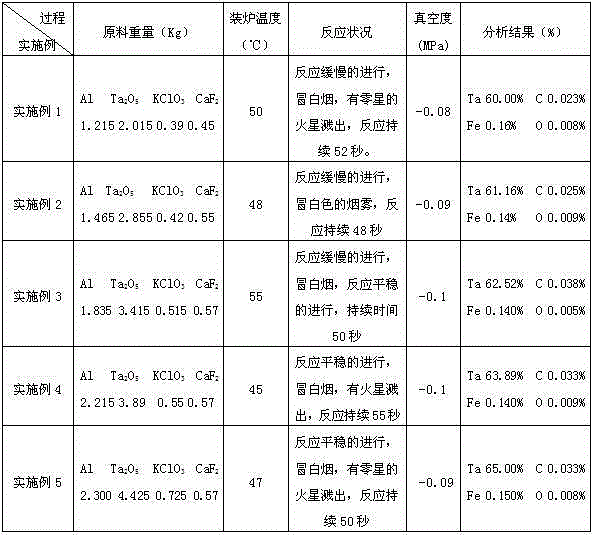

Embodiment 2~5

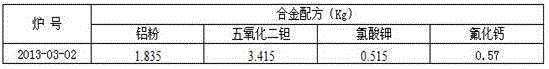

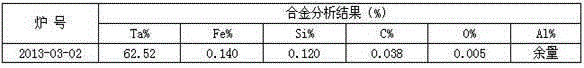

[0028] Embodiment 2~5, operate according to the method of embodiment 1, see the table below for the difference with embodiment 1.

[0029] Table 3 Aluminum-tantalum alloy embodiment

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a preparation method of an aluminum-tantalum alloy and relates to a preparation method of an intermediate alloy for producing a titanium alloy. The preparation method of the aluminum-tantalum alloy is characterized in that a vacuum aluminothermic reduction method is adopted for preparing the aluminum-tantalum alloy, and the aluminum-tantalum alloy is obtained by using aluminum and tantalum pentoxide as raw materials and by virtue of smelting by the vacuum aluminothermic reduction method. Compared with the prior art, the preparation method of the aluminum-tantalum alloy has the beneficial effects that the preparation of the titanium alloy can be carried out conveniently, the intermediate alloy obtained by the preparation method is used for preparing the titanium alloy, sponge titanium can be added in an alloy ladle, and when the titanium alloy is smelted by using a consumable electrode vacuum furnace, current can be controlled easily due to even components of an ingot, and therefore, the titanium alloy can be prepared conveniently; the alloy smelting method can be used for effectively solving the problem of easy segregation of the titanium alloy and overcoming the defects of poor compatibility and high content of gaseous phase impurities, and is convenient for titanium alloy production and operation. The preparation method of the aluminum-tantalum alloy has the advantage of being convenient for preparing the titanium alloy and the advantage of easiness for storage and transportation.

Description

technical field [0001] The invention discloses a method for preparing an aluminum-tantalum alloy, relating to a method for preparing a master alloy for producing a titanium alloy. Background technique [0002] Metal tantalum can be used as a structural material for the combustion chamber of an aircraft engine. Tantalum tungsten and tantalum hafnium alloys are used as heat-resistant high-strength materials for rockets, missiles and engines, as well as parts of control and regulation equipment. Tantalum nitrides and their alloys can be used as Heat release elements and liquid metal sheath materials in the atomic energy industry. Because the titanium-tantalum alloy produced by directly adding tantalum metal has poor compatibility and a large degree of alloy segregation, the production process of directly adding simple metal is generally not used. [0003] At present, the preparation method of aluminum-tantalum alloy is usually prepared by an out-of-furnace thermite method, for...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B5/04C22C27/02C22C1/02

Inventor 王志军刘建丰刘强朱艳彬胡利志

Owner CHENGDE TIANDA VANADIUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com