Preparation method of macromolecular multi-layered hydrogel drug sustained-release material

A technology of slow-release materials and polymers, which is applied in the preparation of polymer polyelectrolyte drug sustained-release materials and the field of multi-layer hydrogel drug sustained-release materials, which can solve the problems of inability to achieve therapeutic effects, long time-consuming, low drug concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the first step, sodium alginate and water are 10%:90% by weight, calcium carbonate-gluconolactone system (a sodium alginate cross-linking agent, wherein the molar ratio of calcium carbonate and gluconolactone is 1:2) According to 20% of the weight of sodium alginate, the drug methylene blue is compounded according to the total weight of sodium alginate and water 4%, and the polyanionic polymer blend A is obtained by degassing and stirring with a vacuum defoaming mixer.

[0040] Chitosan and water are mixed according to the weight percentage of 10%: 90%, genipin (which is chitosan cross-linking agent) is mixed according to 10% of the mass of chitosan, and the drug methylene blue is prepared according to the total weight of chitosan and water 1%. , and the vacuum defoaming mixer defoaming and stirring evenly to obtain polycationic polymer blend B.

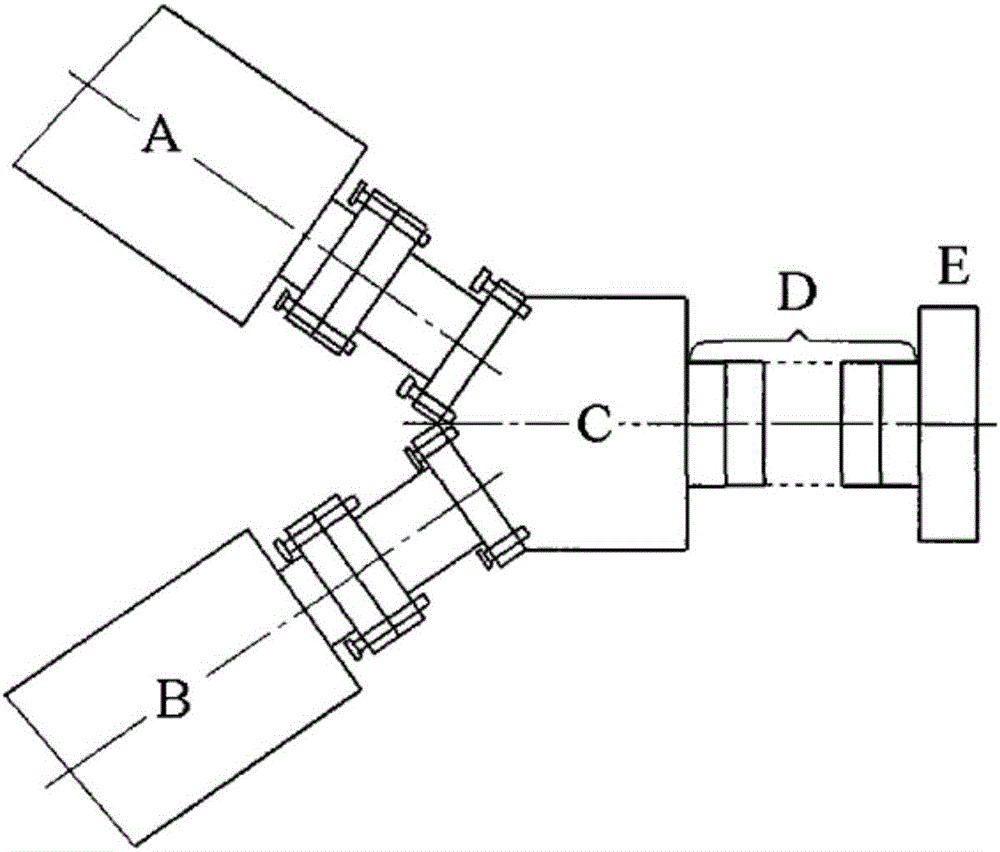

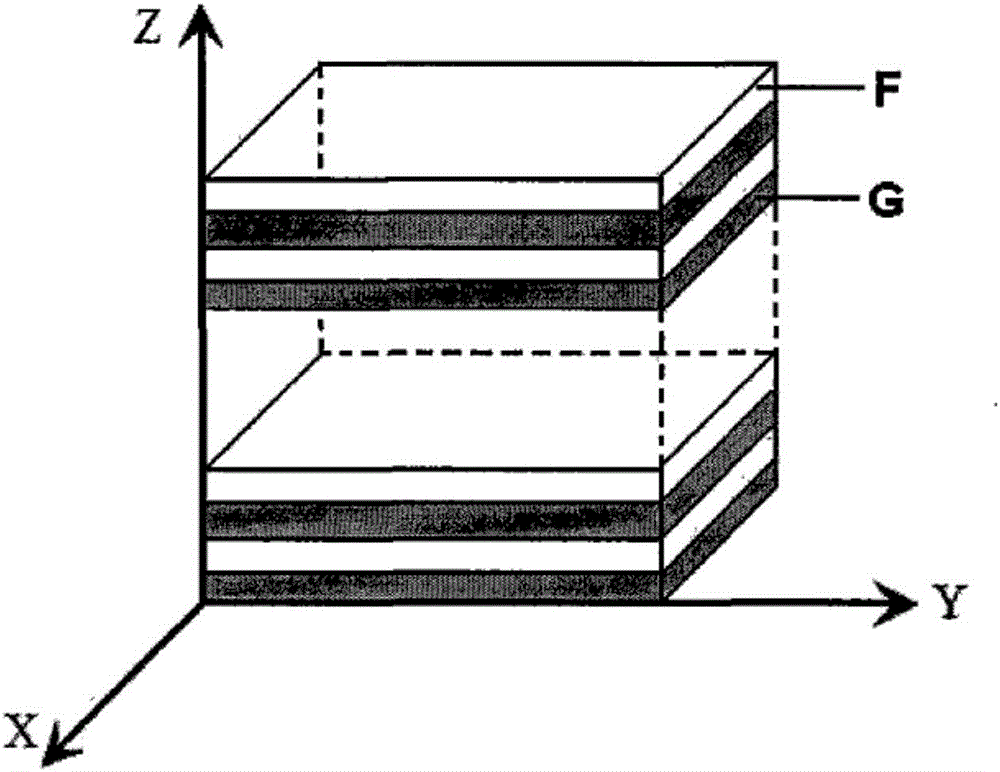

[0041] In the second step, the uniformly mixed sodium alginate blend solution (polyanionic polymer blend solution A) and ...

Embodiment 2

[0046] In the first step, the weight percentage of sodium alginate and water is 10%: 90%, calcium sulfate (as a sodium alginate crosslinking agent) is 20% of the weight of sodium alginate, and the drug methylene blue is 10% of the total weight of sodium alginate and water. % carry out batching, and obtain the polyanionic macromolecular blend liquid A evenly through vacuum defoaming mixer defoaming and stirring.

[0047] Chitosan and water are mixed according to the weight percentage of 10%: 90%, genipin (which is chitosan cross-linking agent) is mixed according to 10% of the mass of chitosan, and the drug methylene blue is prepared according to the total weight of chitosan and water 1%. , and the vacuum defoaming mixer defoaming and stirring evenly to obtain polycationic polymer blend B.

[0048] In the second step, the uniformly mixed sodium alginate blend solution (polyanionic polymer blend solution A) and chitosan blend solution (polycation polymer blend solution B) were ex...

Embodiment 3

[0053]In the first step, the weight percentage of hyaluronic acid and water is 30%: 70%, glutaraldehyde (as a hyaluronic acid crosslinking agent) is 5% of the weight of hyaluronic acid, and the drug ibuprofen is mixed with hyaluronic acid and water. The total weight is 30% for batching, and the polyanionic polymer blend A is obtained by degassing and stirring with a vacuum defoaming mixer.

[0054] Mix gelatin and water at 20%:80% by weight, glutaraldehyde (gelatin cross-linking agent) at 2% of the gelatin mass, drug ibuprofen at 10% of the total weight of gelatin and water, and vacuum defoam The mixer degasses and stirs evenly to obtain the polycationic polymer blend B.

[0055] In the second step, the above-mentioned homogeneously mixed hyaluronic acid blend solution (polyanionic polymer blend solution A) and gelatin blend solution (polycation polymer blend solution B) are respectively stirred by an extruder at 25°C extruded, and stacked together at the outlet of the conflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com