Firework touch off base material taking amylum as base and method for preparing

A technology of starch and fireworks, which is applied in pyrotechnics, offensive equipment, textiles and papermaking, etc. It can solve problems such as complex process, unfavorable environmental protection, and influence on launch effect, and achieve simple process, stable product quality index, and labor saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

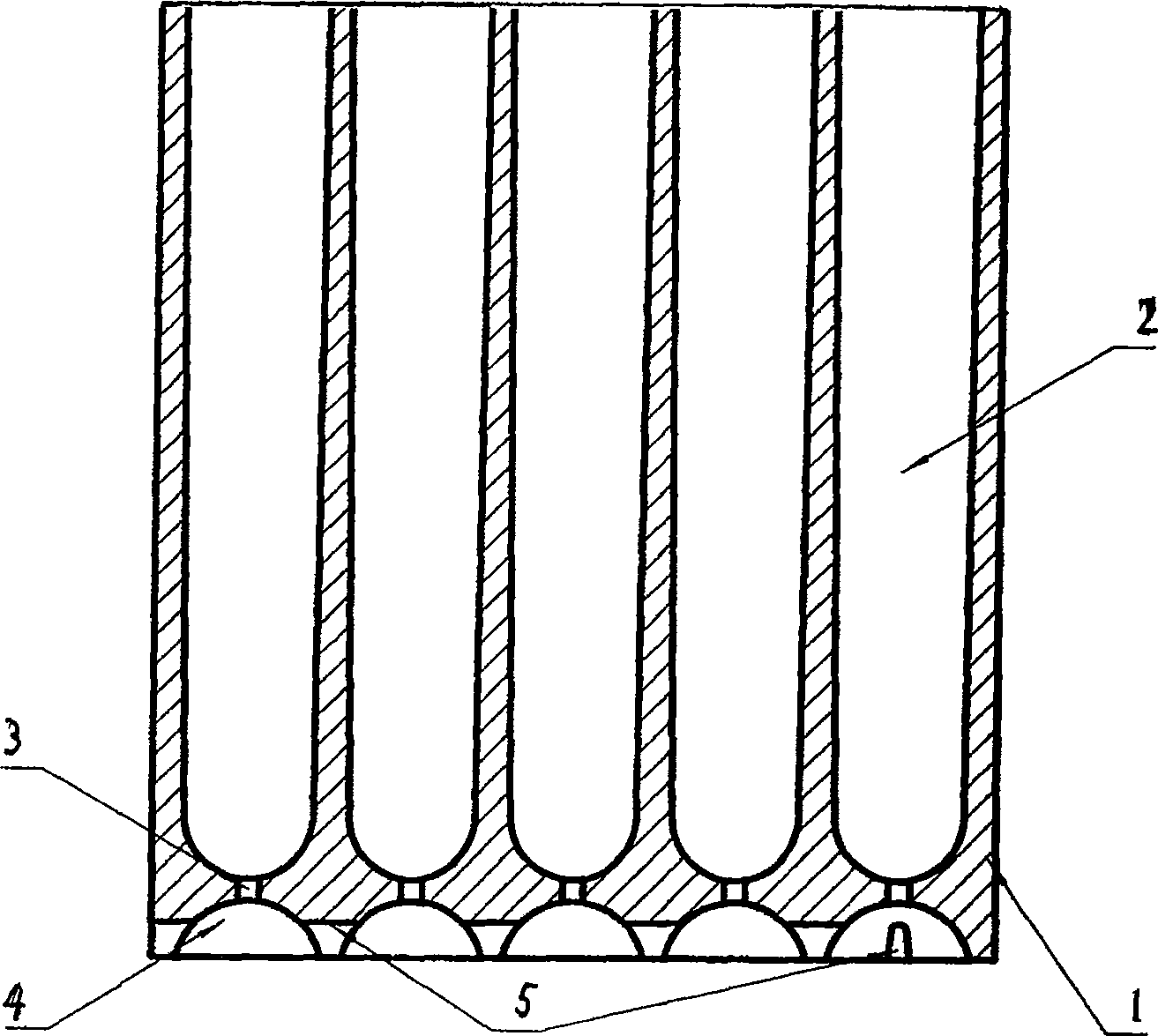

Image

Examples

preparation example Construction

[0028] The preparation method of the firework setting off base is to add 0.6-3.5 times the water of the total amount of starch after disintegrating the pulp, then add 5%-60% of the starch and stearic acid in the release agent, stir evenly and then stir Heat until the starch is completely gelatinized, cool slightly, add the remaining ingredients, mix thoroughly to form a mud, take the mud suitable for the mold cavity, fill it into a mold with a mold temperature of 150-280°C, close the mold and keep it warm until Dry and release the mold to get the product.

[0029] If inorganic fillers are used, after the starch is completely gelatinized, cool slightly, and then add 0.01-0.2 times the amount of starch release agent, 0.5-4 times the amount of starch inorganic fillers and the rest of the starch.

example 1

[0031] Example 1. Take 100g of coniferous wood pulp, filter it with hydraulic disintegration, squeeze it dry, add water to adjust the total weight to 700g, add 50g starch and 10g stearic acid, stir well, and heat until the starch is completely gelatinized while stirring. Cool slightly, then add 950g of starch and 500g of talcum powder, and mix well. Take an appropriate amount of the mixture and fill it into a firework discharge tube mold with a mold temperature of 150°C, keep it warm until no steam is released, and then take it out of the mold.

example 2

[0032] Example 2. Take 1 kg of waste paper, disintegrate it with water, filter it, squeeze it dry, add water to adjust the total weight to 4.5 kg, add 0.6 kg of starch and 100 g of stearic acid, stir well, and heat until the starch is completely gelatinized while stirring. Cool slightly, then add 0.4kg of starch, 100g of zinc stearate, 2.5kg of talcum powder, and 1.5kg of clay powder, and mix well. Take an appropriate amount of the mixture and fill it into the mold of the combined fireworks launcher with a mold temperature of 280°C, keep it warm until no steam is discharged, and then take it out of the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com