Lithium ion powder battery liquid cooling structure

A power battery, liquid cooling technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of high battery operating temperature and uneven temperature distribution of battery packs, achieve excellent performance, ensure safe and effective operation, and novel structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

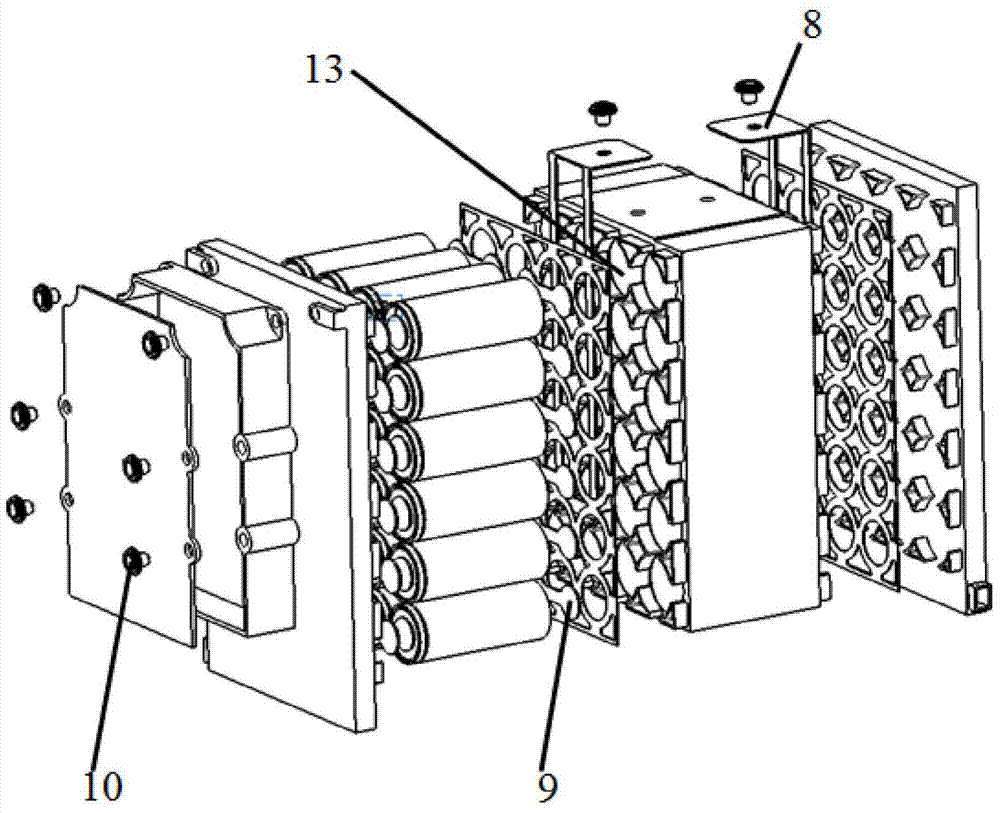

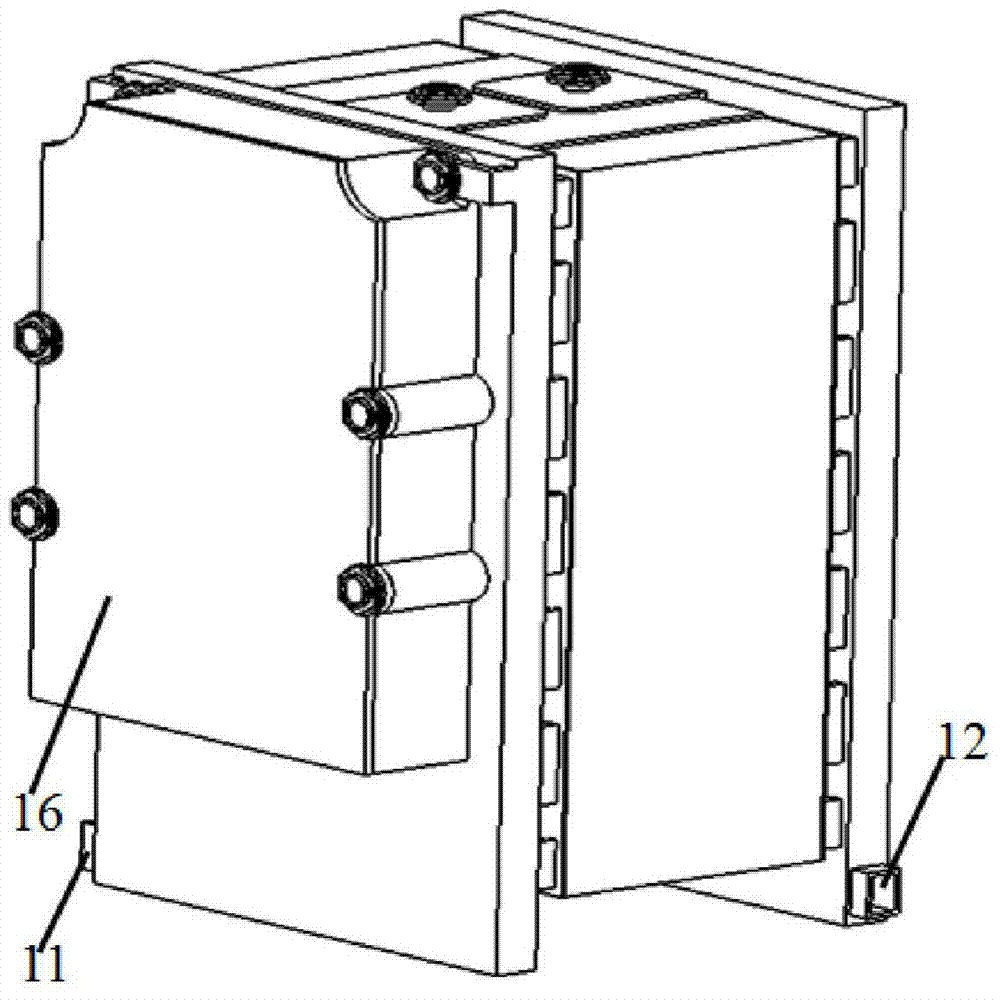

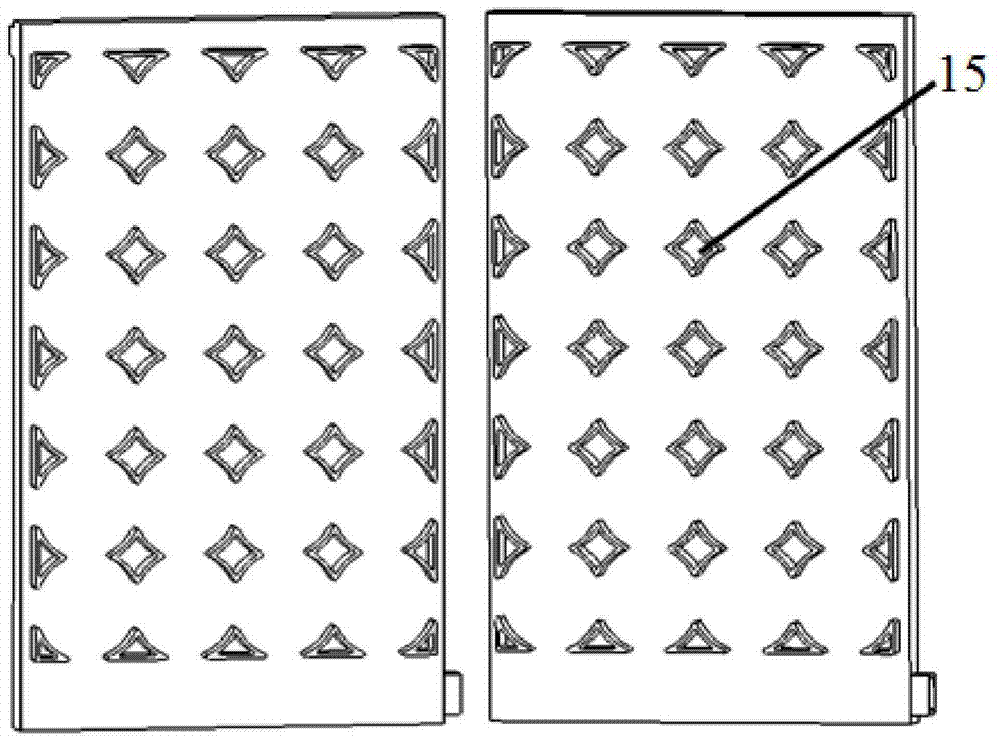

[0025] A lithium-ion power battery liquid cooling structure as shown in the present invention, the structure includes a main body frame, a water inlet end cover, a water outlet end cover, a gasket, a battery cell, a monitoring device main body, a monitoring device end cover, and a manifold 8 , busbar 9 and bolts 10 and other components. The water inlet end cover and the water outlet end cover are connected with the main frame through interference fit, forming 24 cylindrical cavities 13 and 35 coolant flow channels 14, 15; the gaskets are arranged between the end cover and the main frame The battery cells are installed in the cylindrical cavity 13, and the battery cells are connected in parallel through the busbar 9, and the positive and negative electrodes are drawn out through the busbar 8, and the busbar 8 is fixed on the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com