Preparation method and application method of nitrogen-doped porous carbon based on straw hydrothermal carbonization

A technology of hydrothermal carbonization and nitrogen doping, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of waste of biological resources, air pollution, etc., and achieve renewable cost, high specific capacitance, and high value effect of chemical utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

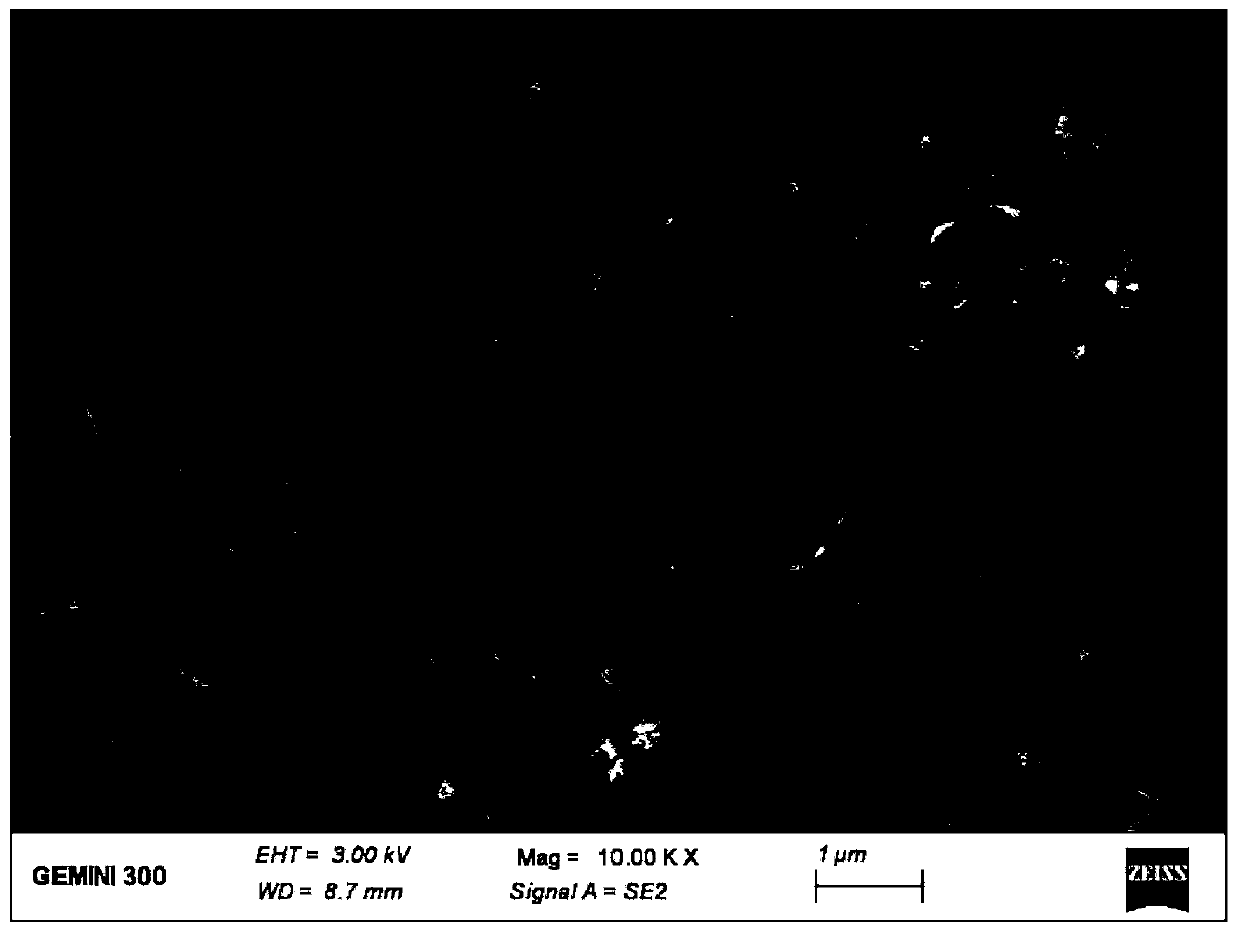

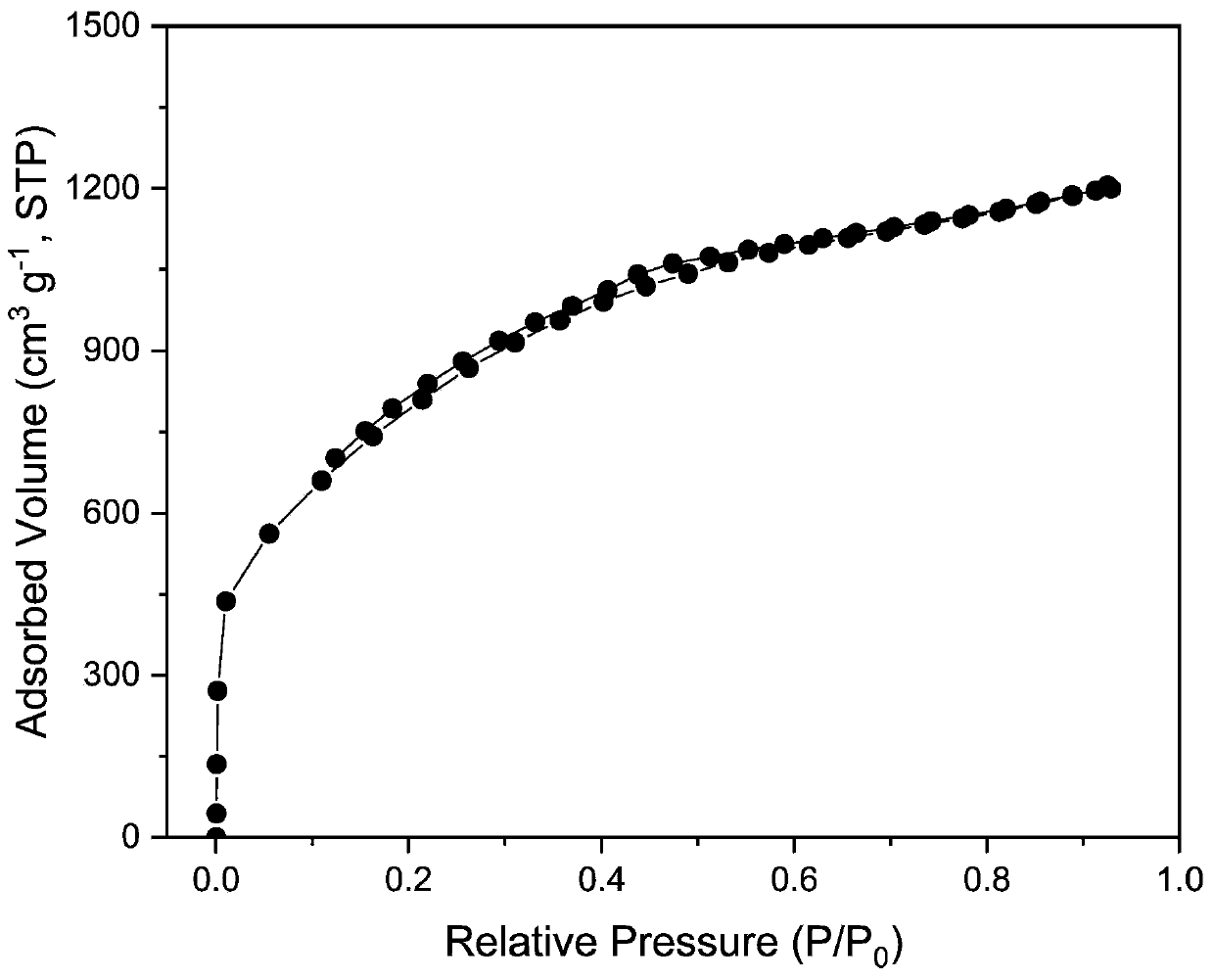

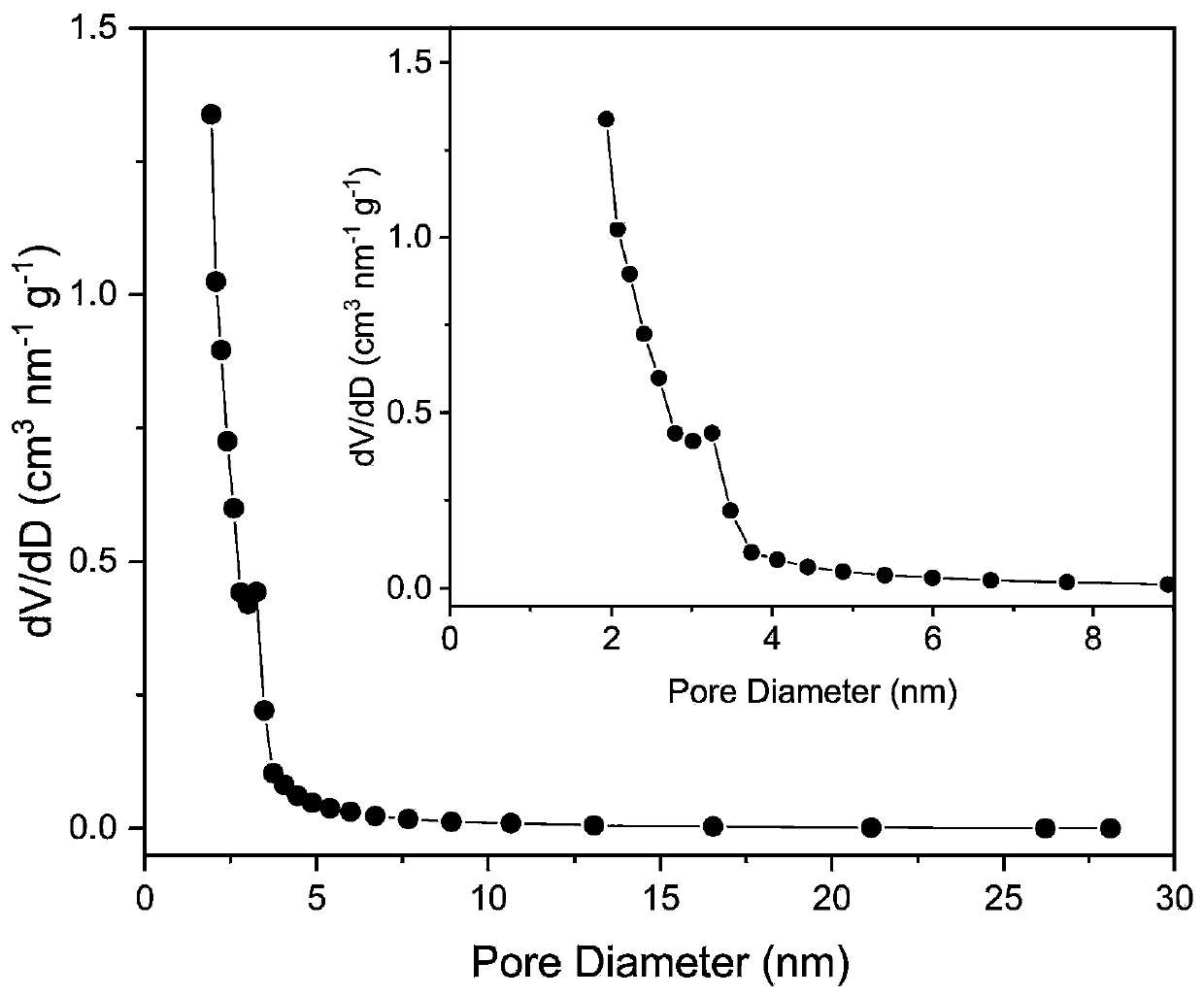

[0037]The raw rice straw was pulverized by a turbine grinder, passed through a 40-mesh standard sieve, and then dried in a blast drying oven at 105°C for 12 hours. Soak 50g of crushed straw raw material in 500ml of ionized water, ultrasonicate at room temperature for 1h, then seal it in a high-temperature and high-pressure reaction kettle with a quartz lining, heat it to 240°C, keep it warm for 4h, and the stirring speed during the hydrothermal reaction process is 100r / min. Naturally cool to room temperature after the reaction is completed, filter with suction, wash with absolute ethanol and ultrapure water to remove impurities, and dry at 105°C for 12 hours to obtain brown-black straw hydrothermal charcoal. The straw hydrothermal charcoal, potassium bicarbonate and melamine are mixed in a mass ratio of 1:6:1 and then fully ground in a mortar. The obtained mixture was placed in a tube furnace, and the temperature was raised to 850° C. at a rate of 5° C. / min under a nitrogen ...

Embodiment 2

[0045] The raw rice straw was pulverized by a turbine grinder, passed through a 40-mesh standard sieve, and then dried in a blast drying oven at 105°C for 12 hours. Soak 50g of crushed straw raw material in 750ml of ionized water, ultrasonicate at room temperature for 1h, then seal it in a high-temperature and high-pressure reaction kettle with a quartz lining, heat it to 240°C, keep it warm for 4h, and the stirring speed during the hydrothermal reaction is 100r / min. Naturally cool to room temperature after the reaction is completed, filter with suction, wash with absolute ethanol and ultrapure water to remove impurities, and dry at 105°C for 12 hours to obtain brown-black straw hydrothermal charcoal. The straw hydrothermal charcoal, potassium bicarbonate and melamine are mixed in a mass ratio of 1:6:1 and then fully ground in a mortar. The obtained mixture was placed in a tube furnace, and the temperature was raised to 850° C. at a rate of 5° C. / min under a nitrogen atmosph...

Embodiment 3

[0047] The raw rice straw was pulverized by a turbine grinder, passed through a 40-mesh standard sieve, and then dried in a blast drying oven at 105°C for 12 hours. Soak 50g of crushed straw raw material in 500ml of ionized water, ultrasonicate at room temperature for 1h, then seal it in a high-temperature and high-pressure reactor with a quartz lining, heat it to 220°C, keep it warm for 4h, and the stirring speed during the hydrothermal reaction process is 100r / min. Naturally cool to room temperature after the reaction is completed, filter with suction, wash with absolute ethanol and ultrapure water to remove impurities, and dry at 105°C for 12 hours to obtain brown-black straw hydrothermal charcoal. The straw hydrothermal charcoal, potassium bicarbonate and melamine are mixed in a mass ratio of 1:6:1 and then fully ground in a mortar. The obtained mixture was placed in a tube furnace, and the temperature was raised to 850° C. at a rate of 5° C. / min under a nitrogen atmosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com