Magnetic element with permanent magnetic bias

A technology of magnetic components and permanent magnets, applied in the field of magnetic components, can solve the problems of permanent magnet temperature failure, large eddy current loss, permanent magnet demagnetization, etc., and achieve the effect of improving anti-biasing ability, reducing cross-sectional area, and increasing inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0020] The invention takes the inductor coil element as an example, but is not limited thereto. It can also be applied to the structure of combined magnetic components that need to use permanent magnetic materials to improve the anti-biasing ability of the magnetic core of the magnetic circuit, such as transformers, multi-channel output integrated inductors and the like. Specific examples are as follows:

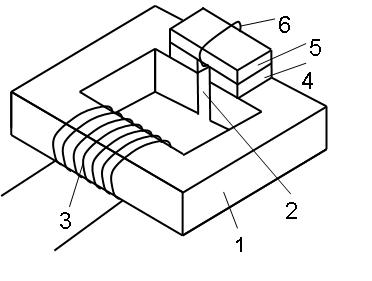

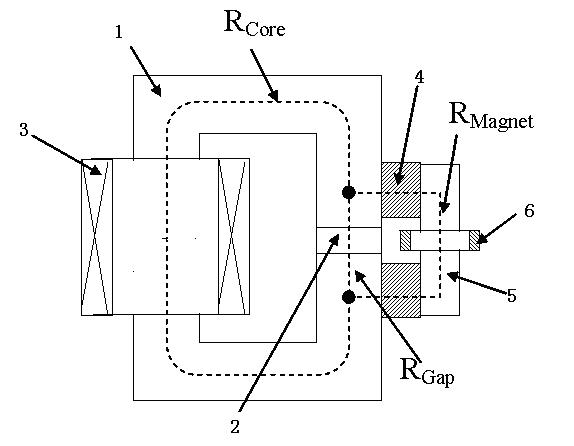

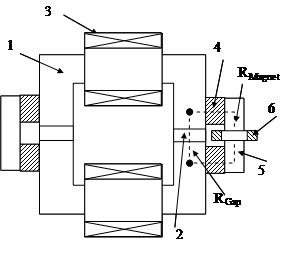

[0021] Figure 6 It is composed of a magnetic core 1, a coil 3, two air-gap fractures 2 of two high-side columns, four permanent magnets 4, a soft magnetic material 5, and a short-circuit coil 6 with at least one turn. The thin arrows (polarization direction and bias direction of the permanent magnet) appear opposite to the thick arrows (the direction of the magnetic field generated by the DC coil), and can be reversed at the same time. Due to the biasing effect of the permanent magnet, the direct current power passed through the working coil can be greatly increased. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com