A self-compensating concrete-integrated strain gauge

A self-compensating, concrete technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring devices, etc., can solve the problem of not strictly correcting the influence of wire resistance detection sensitivity, the inconsistency of the influence of wire resistance on detection sensitivity, and the difference in the length of connecting wires Larger problems, etc., to achieve the effect of safe positioning, convenient on-site installation, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

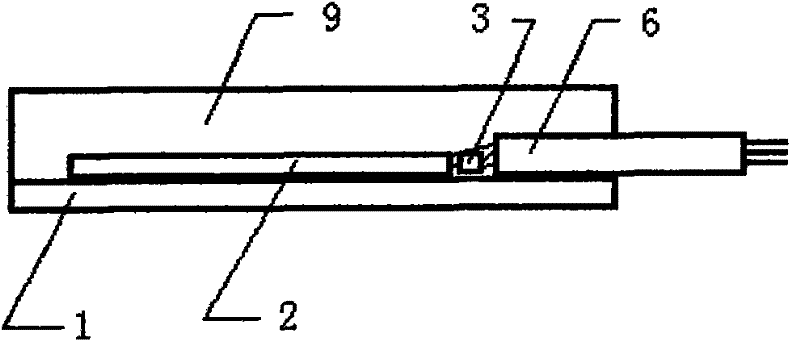

[0026] as attached figure 1 And attached figure 2 A self-compensating concrete integrated strain gauge is shown, which uses an epoxy resin glass fiber substrate, a long gauge temperature self-compensating strain gauge, and a precision non-inductive wire-wound resistor as compensation resistors. Strain gauges and precision non-inductive wire-wound resistors form a half-bridge circuit, connected to three-core wires, and are treated with silicone for overall waterproof sealing.

Embodiment 2

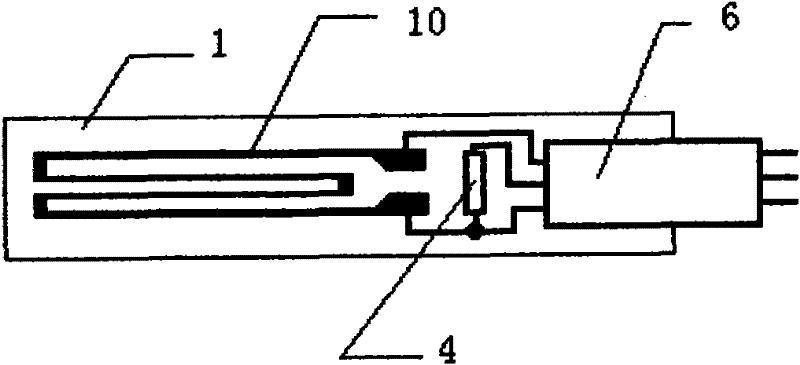

[0028] as attached image 3 A self-compensating concrete integrated strain gauge is shown. The strain sensitive resistor and the compensation resistor adopt foil strain gauges of the same material and resistance value. The strain sensitive resistor is a long gauge strain gauge, and the compensation resistor is a small gauge gauge strain gauge. The sensitive direction of the small gauge gauge is perpendicular to the long gauge gauge.

[0029] All the other are with embodiment 1.

Embodiment 3

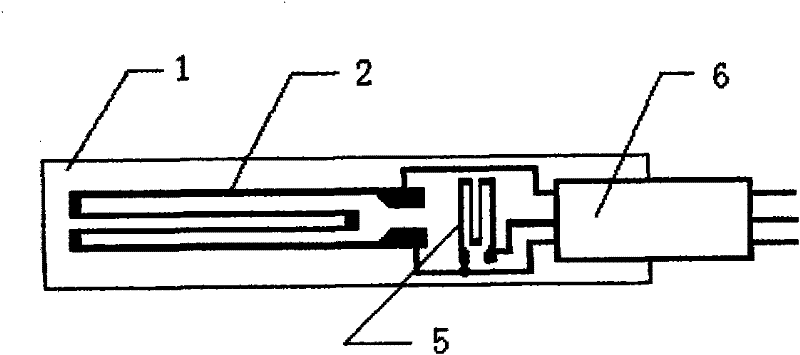

[0031] as attached Figure 4 A self-compensating concrete integrated strain gauge is shown, the strain sensitive resistor and the compensation resistor adopt foil strain gauges of the same material and resistance value, the strain sensitive resistor is a long gauge strain gauge, and the compensation resistor is a small gauge gauge strain gauge , the compensation sheet of the small gauge strain gauge is installed on the stress-free substrate, and the stress-free substrate is realized by suspending the small steel sheet in the fluid silica gel.

[0032] All the other are the same as embodiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com