Double heat accumulation type high-temperature oxygen-deficient combustor with oxygen-enriched air supply

A technology of lean oxygen combustion and double heat storage, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of oxidative burning loss and aggravated production of nitrogen oxides, and achieve temperature increase, momentum increase, and increase The effect of heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

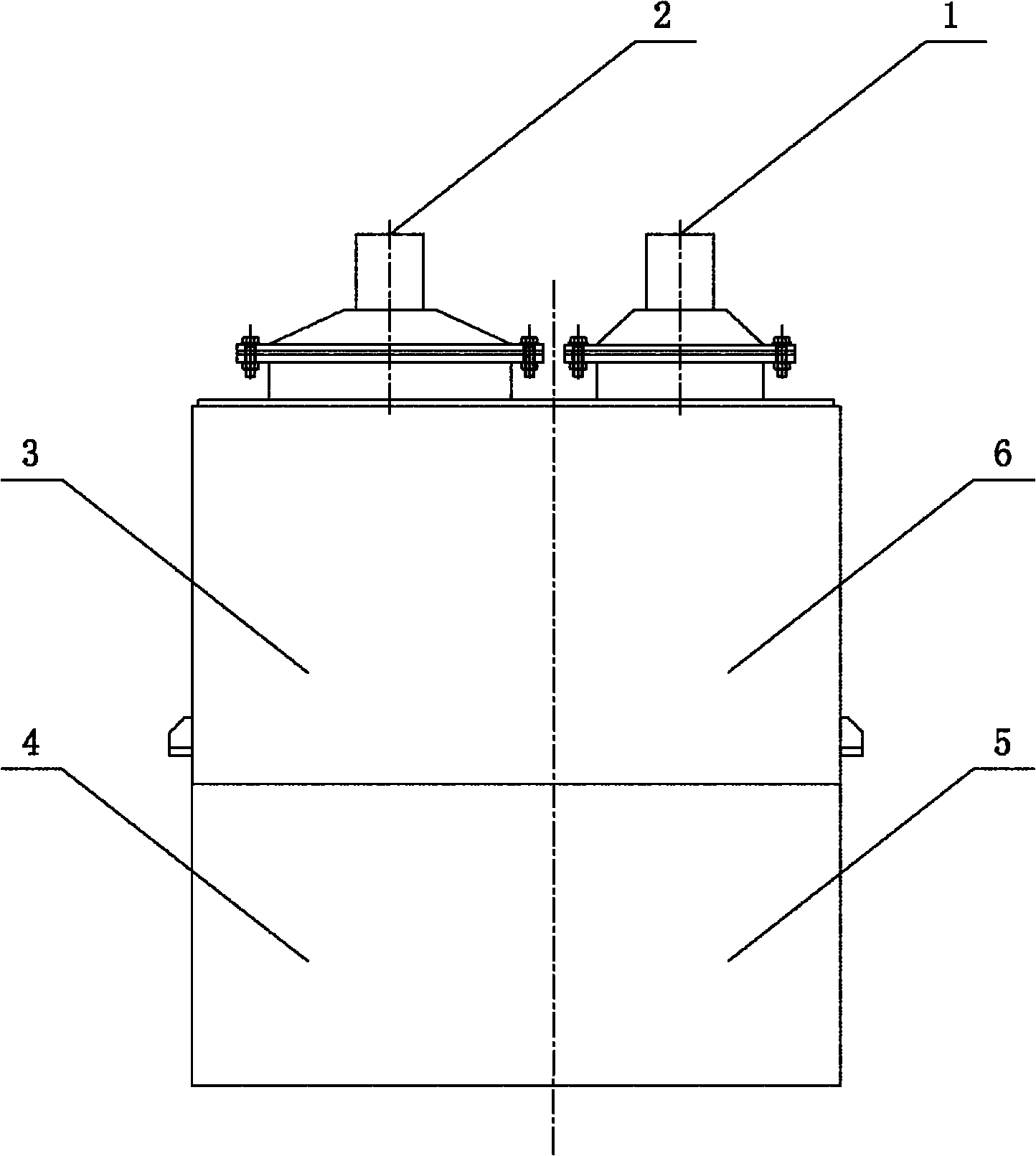

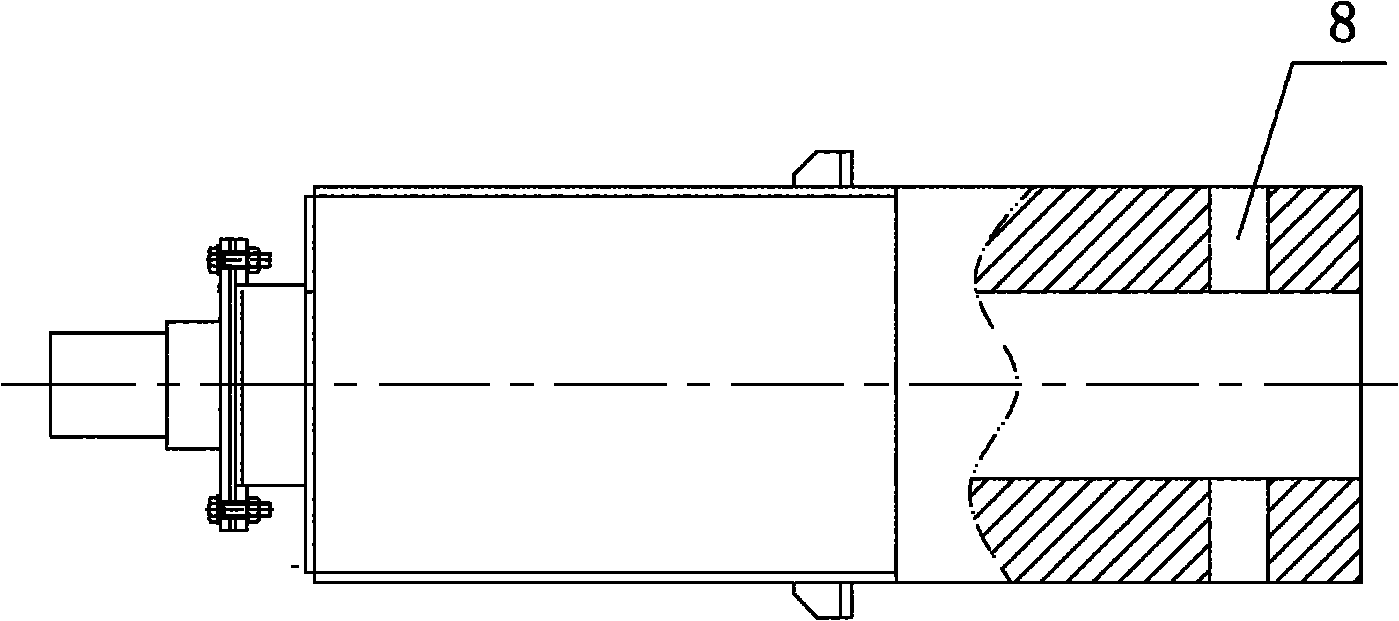

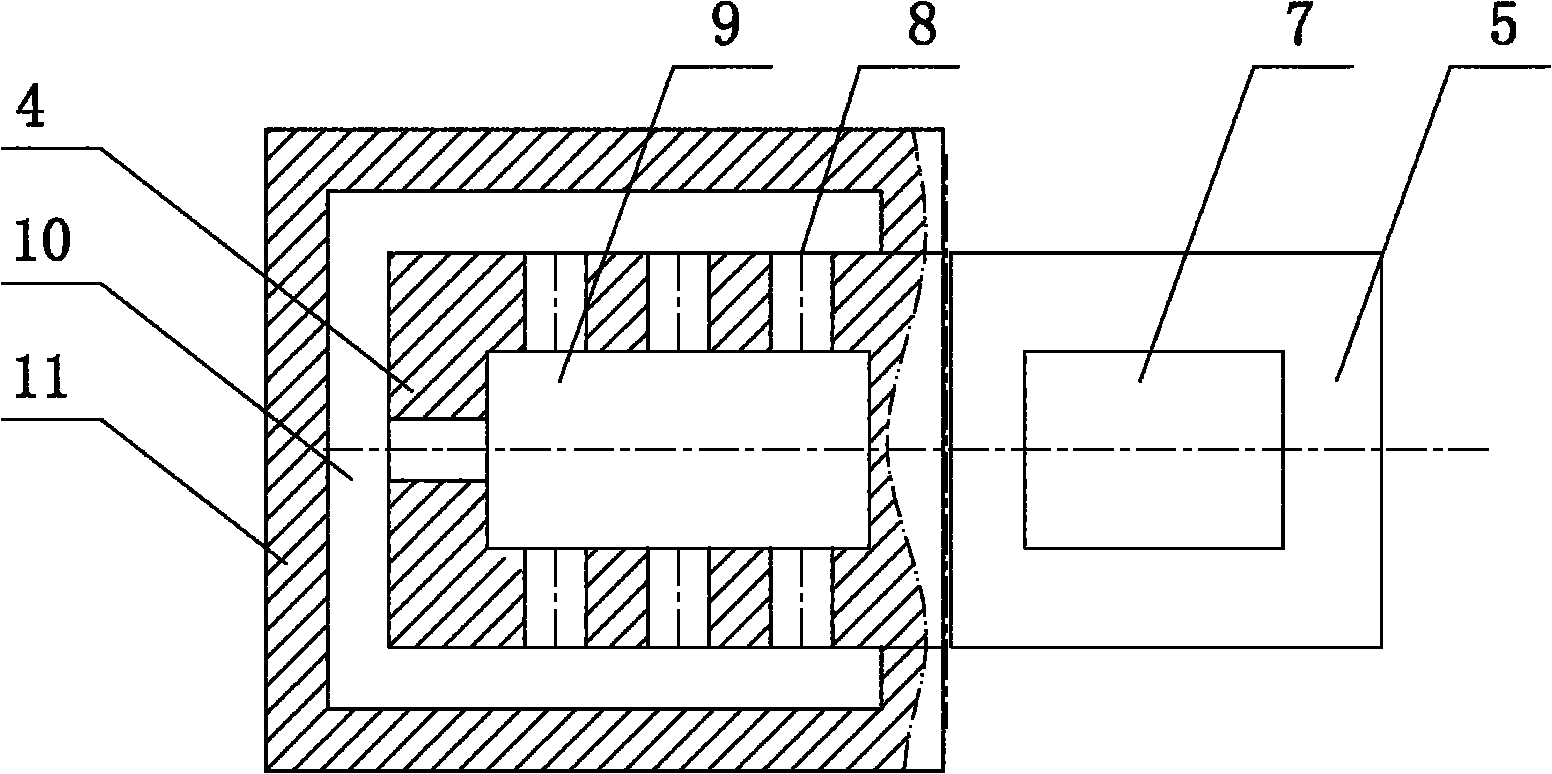

[0015] The invention includes gas inlet / flue gas outlet 1, oxygen-enriched air inlet / flue gas outlet 2, oxygen-enriched air regenerator box 3, oxygen-enriched air spout brick 4, gas spout brick 5, gas regenerator box 6, gas Nozzle 7, flue gas circulation channel 8, oxygen-enriched air and flue gas mixture gas nozzle 9, flue gas return port 10, flue gas return vent brick 11. The gas inlet / flue gas outlet 1 is connected to the pipeline of the gas outlet / flue gas inlet of the reversing valve, and the oxygen-enriched air inlet / flue gas outlet 2 is connected to the pipeline of the oxygen-enriched air outlet / flue gas outlet of the reversing valve. Gas inlet / flue gas outlet 1 and oxygen-enriched air inlet / flue gas outlet 2 are connected to the burner side by side, oxygen-enriched air regenerator box 3 is located behind oxygen-enriched air inlet / flue gas outlet 2, oxygen-enriched air regenerator box 3 is connected to the oxygen-enriched air nozzle brick 4, the flue gas circulation cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com