Rare earth aluminum alloy foam and preparation method thereof

An aluminum alloy foam and rare earth technology, which is applied in the field of alloys to achieve the effects of low oxidation burnout rate and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

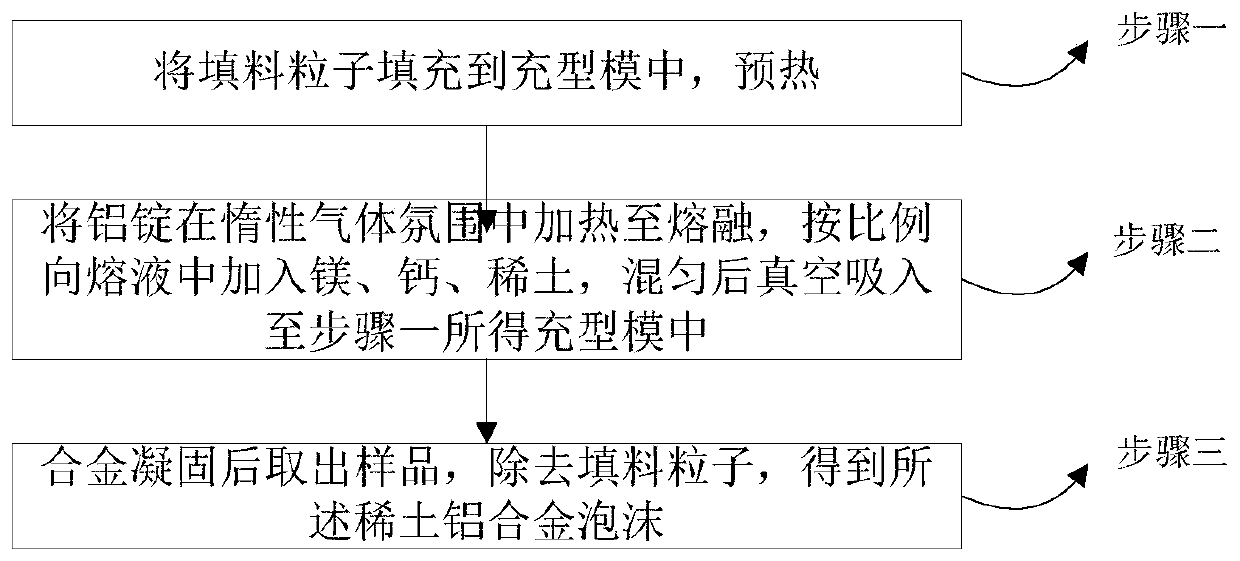

[0023] like figure 1 As shown, the embodiment of the present invention provides a method for preparing a rare earth aluminum alloy foam, comprising the following steps:

[0024] Step 1, filling filler particles into the filling mold and preheating;

[0025] Step 2, heating the aluminum ingot in an inert gas atmosphere until it melts, adding magnesium, calcium, and rare earth to the melt in proportion, mixing and sucking it into the filling mold obtained in step 1 by vacuum;

[0026] Step 3, after the alloy is solidified, the sample is taken out, the filler particles are removed, and the rare earth aluminum alloy foam is obtained.

[0027] In the above technical solution, rare earth, magnesium and calcium are added to the molten aluminum, wherein magnesium accounts for 1% to 12% by mass of aluminum, calcium accounts for 0.5% to 4% by mass of aluminum, and rare earth accounts for 1% by mass of aluminum. The mass percentage is 0.10% to 1.2%.

[0028] Rare earth elements play a...

Embodiment 1

[0034] Step 1: Fill filler particles with a particle size of 1.4mm into the filling mold and preheat to 450°C;

[0035] Step 2, heating the aluminum ingot to 750°C in an argon atmosphere to melt, and then adding magnesium accounting for 5% of the mass percentage of aluminum and 2% of calcium accounting for aluminum to the melt in proportion The rare earth with a mass percentage of 1% is sucked into the filling mold obtained in step 1 under the vacuum condition of 0.04-0.06 MPa after mixing;

[0036] Step 3, after the alloy in the die is solidified, the sample is taken out, and the filler particles are removed to obtain the rare earth aluminum alloy foam.

Embodiment 2

[0038] Step 1: Fill filler particles with a particle size of 1.2mm into the filling mold and preheat to 470°C;

[0039] Step 2, heating the aluminum ingot to 790°C in an argon atmosphere to melt, and then adding magnesium accounting for 10% by mass percentage of aluminum, calcium accounting for 1% by mass percentage of aluminum, and The rare earth with a mass percentage of 0.5% is sucked into the filling mold obtained in step 1 under a vacuum condition of 0.04-0.06 MPa after mixing;

[0040] Step 3, after the alloy in the die is solidified, the sample is taken out, and the filler particles are removed to obtain the rare earth aluminum alloy foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com