A method for smelting ultra-advanced duplex stainless steel made of cd3mwn

A technology of duplex stainless steel and process method, which is applied in the metallurgy field of metal materials, and can solve the problems of not very strict requirements, large investment in equipment, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

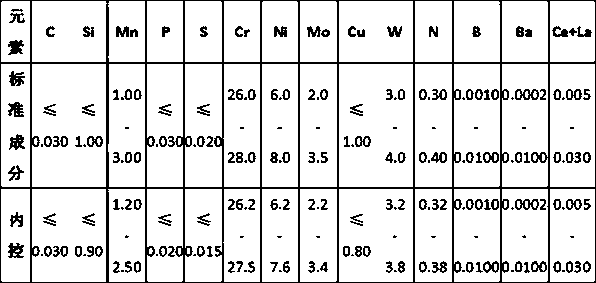

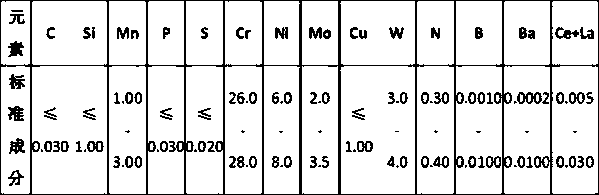

Image

Examples

Embodiment 1

[0060] Luoyang Shuangrui Special Equipment Co., Ltd. adopts the present invention when casting duplex stainless steel pump body castings made of ASTM A890 / A890M CD3MWN, and the implementation process is as follows:

[0061] (1) Prepare the alloy charge required for smelting ASTM A890 / A890M CD3MWN duplex stainless steel, pure iron, metallic chromium, ferrochromium nitride, electrolytic nickel, molybdenum bar, tungsten bar, crystalline silicon, electrolytic manganese, CD3MWN material return charge, lanthanum Cerium alloy (alloy block size 26-32mm, La+Ce content 99.1%), boron iron (alloy block size 16-23mm, B content 22%) and silicon-barium alloy (alloy block size 12-28mm, Ba content 26.1%, Si content is 45.8%.) etc. and slagging materials bagged active lime and fluorite etc.

[0062] (2) Medium frequency induction furnace is used for melting, and the furnace lining is made of neutral material.

[0063] (3) Active lime accounting for 1.2% of the mass of molten steel is added to ...

Embodiment 2

[0084] Luoyang Shuangrui Special Equipment Co., Ltd. adopts the present invention when casting duplex stainless steel impeller castings made of ASTM A890 / A890M CD3MWN, and the implementation process is as follows:

[0085] (1) Prepare the alloy charge required for smelting ASTM A890 / A890M CD3MWN duplex stainless steel, pure iron, metallic chromium, ferrochromium nitride, electrolytic nickel, molybdenum bar, tungsten bar, crystalline silicon, electrolytic manganese, CD3MWN material return charge, lanthanum Cerium alloy (alloy block size 26-32mm, La+Ce content 99.1%), boron iron (alloy block size 16-23mm, B content 22%) and silicon-barium alloy (alloy block size 12-28mm, Ba content 26.1%, Si content is 45.8%.) etc. and slagging materials bagged active lime and fluorite etc.

[0086] (2) Medium frequency induction furnace is used for melting, and the furnace lining is made of neutral material.

[0087] (3) Active lime accounting for 1.1% of the mass of molten steel is added to t...

Embodiment 3

[0107] Luoyang Shuangrui Special Equipment Co., Ltd. adopts the present invention when casting duplex stainless steel impeller castings made of ASTM A890 / A890M CD3MWN, and the implementation process is as follows:

[0108] (1) Prepare the alloy charge required for smelting ASTM A890 / A890M CD3MWN duplex stainless steel, pure iron, metallic chromium, ferrochromium nitride, electrolytic nickel, molybdenum bar, tungsten bar, crystalline silicon, electrolytic manganese, CD3MWN material return charge, lanthanum Cerium alloy (alloy size 20-34mm, La+Ce content 99.2%), boron iron (alloy size 18-24mm, B content 23.5%) and silicon-barium alloy (alloy size 15-25mm, Ba content 25.8%, Si content is 47%.), etc. and slag-making materials bagged active lime and fluorite, etc.

[0109] (2) Medium frequency induction furnace is used for melting, and the furnace lining is made of neutral material.

[0110] (3) Active lime accounting for 1.5% of the mass of molten steel is added to the bottom of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com