Gasification forging continuous reheating furnace

A heating furnace and coal gasification technology, which is applied in the field of heating furnaces for preheating forging blanks, can solve problems such as increasing production costs, reducing production efficiency, and reducing quality of forgings, so as to improve forging quality, prolong service life, and improve heating quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

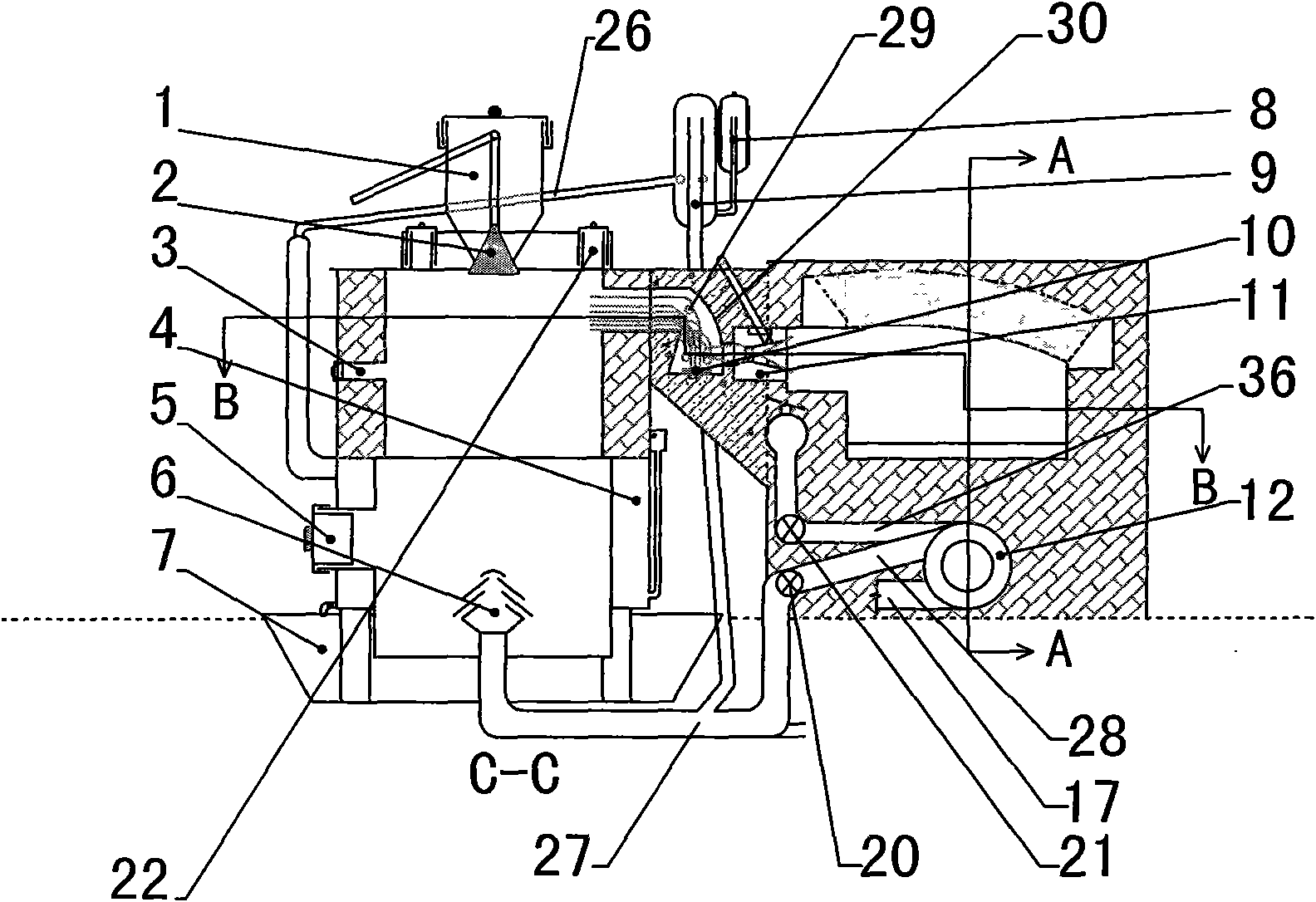

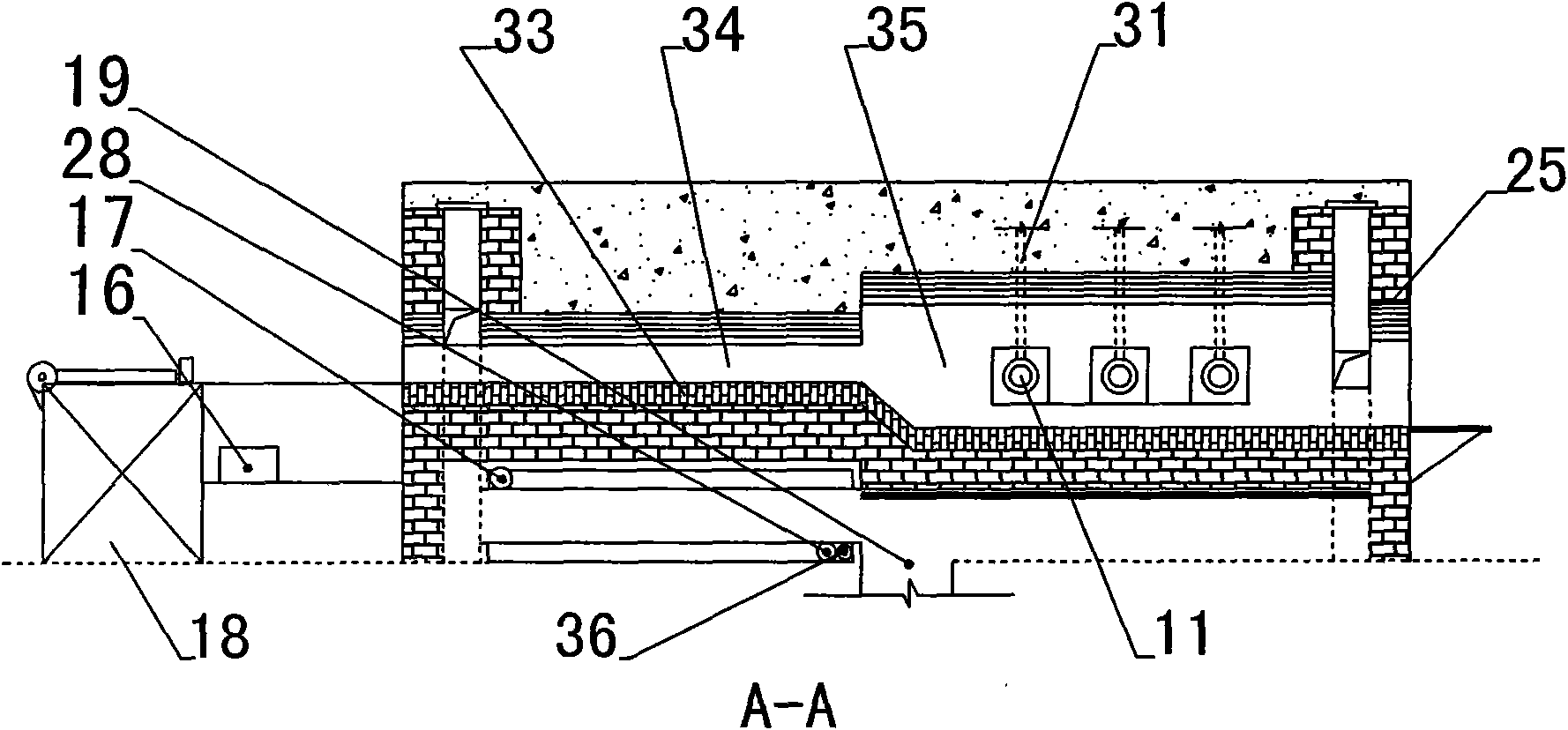

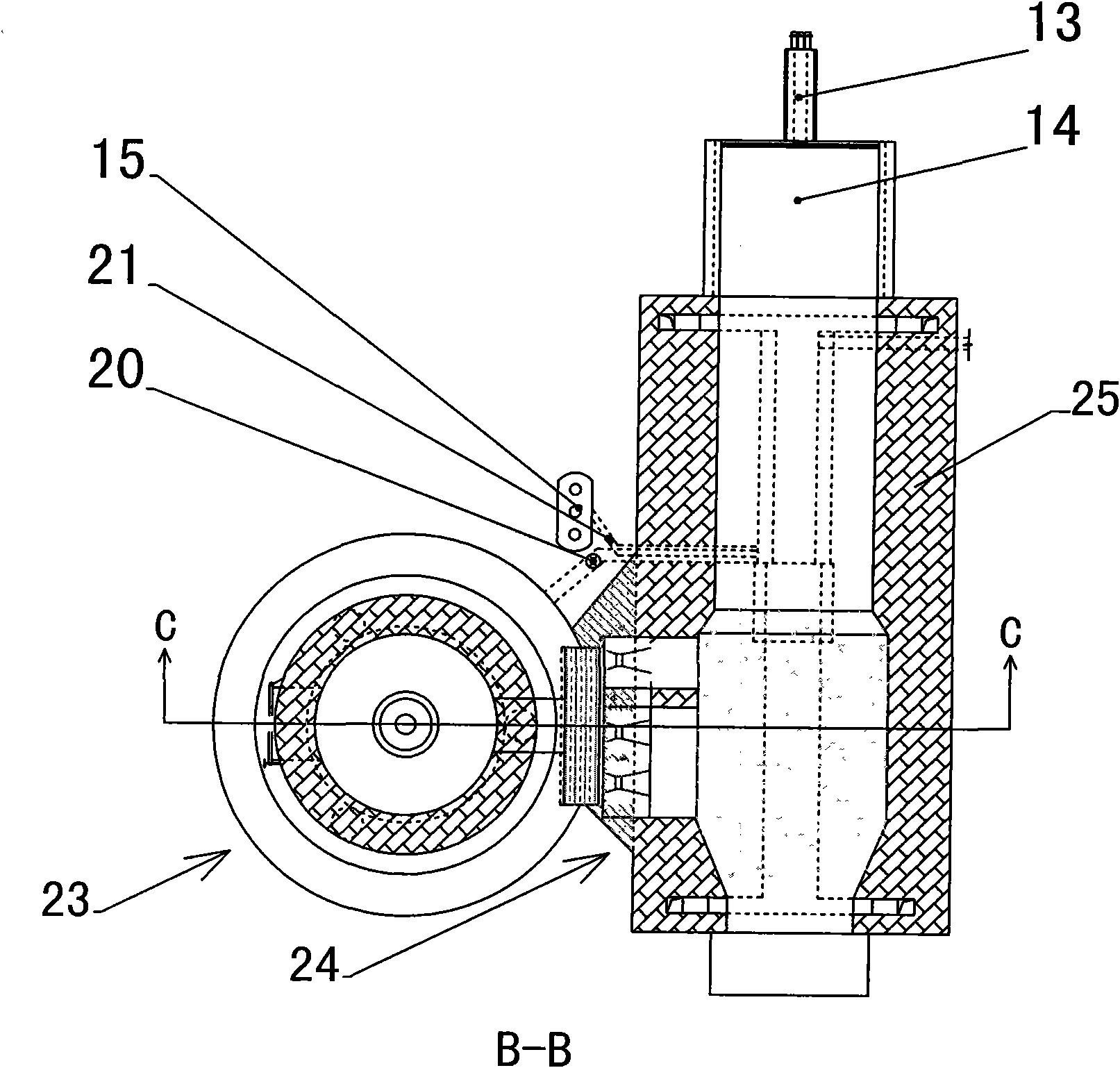

[0022] The coal gasification forging continuous heating furnace is composed of a gas generator 23 and a forging billet heating furnace 24 .

[0023] The gas generator comprises a body of furnace 25, on which a coal hopper 1 and a furnace cleaning hole 22 are installed on the upper cover of the body of furnace 25. A coal discharge valve 2 is provided at the discharge port of the coal hopper 1, and a water jacket 4 is arranged on the inner wall of the furnace part of the furnace body 25. The water jacket 4 is connected with the gas storage tank 9 through a pipeline 26, and the gas storage tank Safety relief valve 8 is installed on the 9. The air storage tank 9 is connected with the primary air inlet pipe 27 through a pipeline. When the water vapor pressure in the air storage tank 9 is greater than the set value, the safety pressure relief valve starts pressure relief. A wind cap 6 is arranged at the lower part of the furnace body 25, and the wind cap 6 is connected with the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com