Method for improving yield of low-carbon high-microalloyed steel

A micro-alloyed steel, yield technology, applied in furnace control devices, lighting and heating equipment, furnace components, etc., can solve the problems of decreased product yield, increased oxidation burning loss, and excessive air volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific examples.

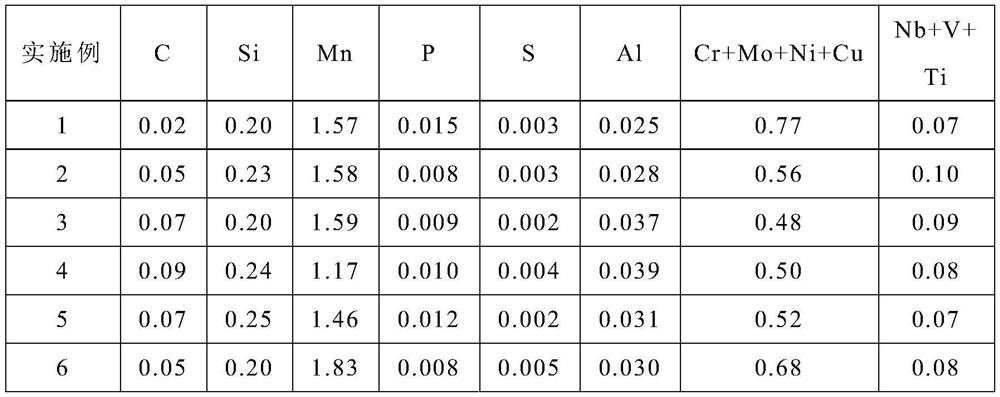

[0018] The steel slab is smelted by the oxygen converter, and the straight arc continuous casting machine is cast into a continuous casting slab. The chemical elements of each component are controlled as shown in Table 1.

[0019] Table 1 Slab Chemical Composition / wt%

[0020]

[0021] The cast slabs in Table 1 are put into the walking heating furnace after surface inspection, and the heating is controlled in sections. The heating rate and furnace temperature of each section are shown in Table 2.

[0022] Table 2 Actual performance of steel billet heating process

[0023]

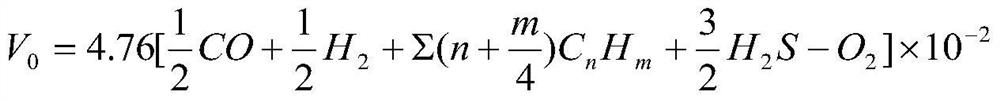

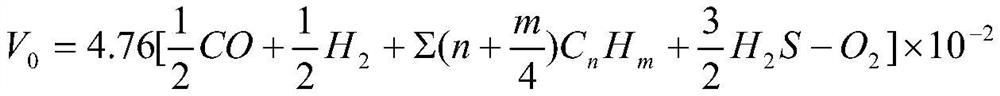

[0024] The atmosphere in the furnace is controlled by the calorific value of the gas and the amount of air introduced, and the actual results are shown in Table 3.

[0025] Table 3 Gas calorific value and air volume control performance

[0026]

[0027] See Table 4 for the scale weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com