Method for improving billet descaling effect

A high-pressure water descaling and steel billet technology, which is applied in the field of steel billet rolling, can solve problems such as iron oxide scale not considered, achieve the effect of reducing rail surface quality problems and improving phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

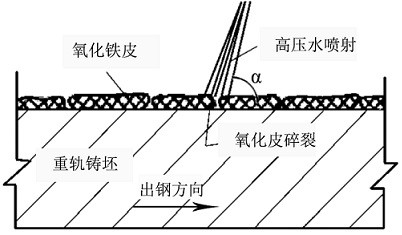

[0031] Before the high-speed heavy rail steel billet is heated in the heating furnace, the anti-oxidation coating is sprayed on the upper surface and two sides of the billet, and the thickness of the coating is 0.25mm. Heating in the heating furnace. After entering the furnace, the temperature of the preheating section is 910°C, the temperature of the heating section is 1178°C, the temperature of the soaking section is 1245°C, the residual oxygen in the furnace is 2%, and the heating time is 4.5h. After being heated by the heating furnace, the surface The thickness of the oxide scale is 1.5mm. After the steel billet leaves the heating furnace, it is descaled by high-pressure water, and the high-pressure water is sprayed obliquely to remove the oxide scale on the surface of the billet. °, the high-pressure water pressure is 22 MPa, which can remove 90% of the oxide scale on the surface of the high-speed heavy rail billet.

Embodiment 2

[0033]Before the high-speed heavy-rail steel billet is heated in the heating furnace, the anti-oxidation coating is sprayed on the upper surface and two sides of the billet. The coating thickness is 0.3mm. The two end faces and the lower surface of the billet are not sprayed with anti-oxidation coating. Heating in the heating furnace. After entering the furnace, the temperature of the preheating section is 920°C, the temperature of the heating section is 1149°C, the temperature of the soaking section is 1240°C, the residual oxygen in the furnace is 1.5%, and the heating time is 6.4h. After being heated by the heating furnace, the surface The thickness of the oxide scale is 1.3 mm. After the steel billet leaves the heating furnace, it is descaled by high-pressure water, and the high-pressure water is sprayed obliquely to remove the oxide scale on the surface of the billet. °, the high-pressure water pressure is 20 MPa, which can remove 92% of the oxide scale on the surface of th...

Embodiment 3

[0035] Before the high-speed heavy rail steel billet is heated in the heating furnace, the anti-oxidation coating is sprayed on the upper surface and two sides of the billet, and the thickness of the coating is 0.35mm. Heating in the heating furnace. After entering the furnace, the temperature of the preheating section is 930°C, the temperature of the heating section is 1223°C, the temperature of the soaking section is 1250°C, the residual oxygen in the furnace is 3%, and the heating time is 5.5h. After being heated by the heating furnace, the surface The thickness of the oxide scale is 0.8mm. After the billet leaves the heating furnace, it is descaled by high-pressure water, and the high-pressure water is sprayed obliquely to remove the oxide scale on the surface of the billet. °, the high-pressure water pressure is 19MPa, which can remove 96% of the oxide scale on the surface of the high-speed heavy rail billet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com