Heat treatment method for improving room-temperature ductility of high-silicon electrical steel

A technology of high silicon electrical steel and heat treatment method, which is applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of limited increase in plasticity of high silicon electrical steel and no consideration of residual stress, so as to improve heat treatment efficiency and reduce Small residual tensile stress, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

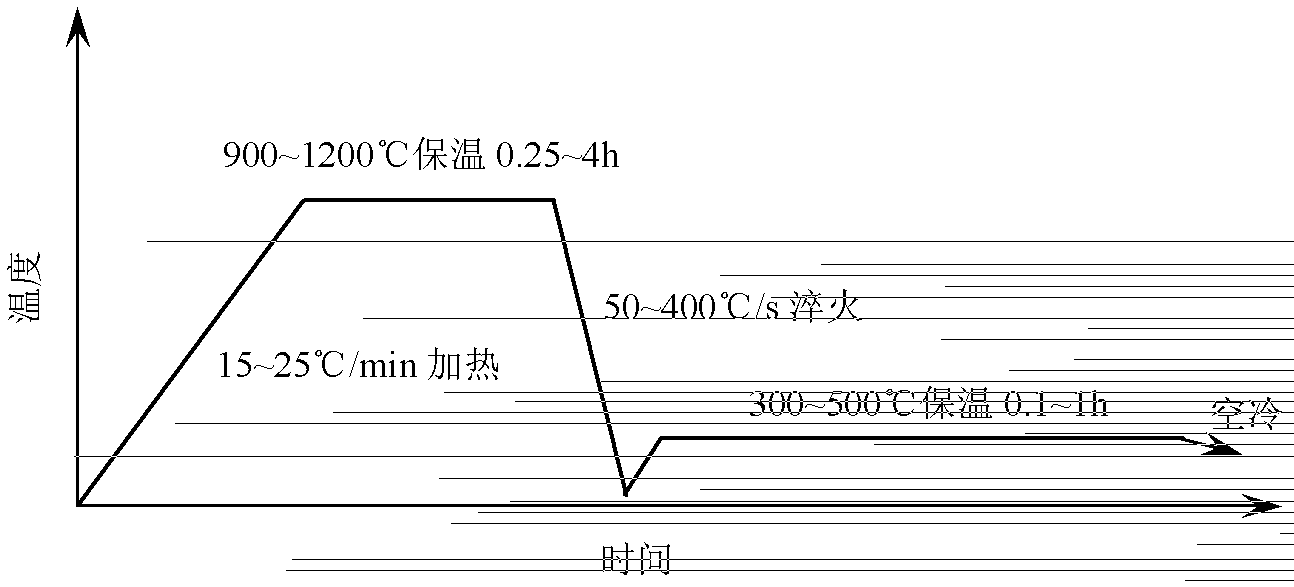

Method used

Image

Examples

Embodiment 1

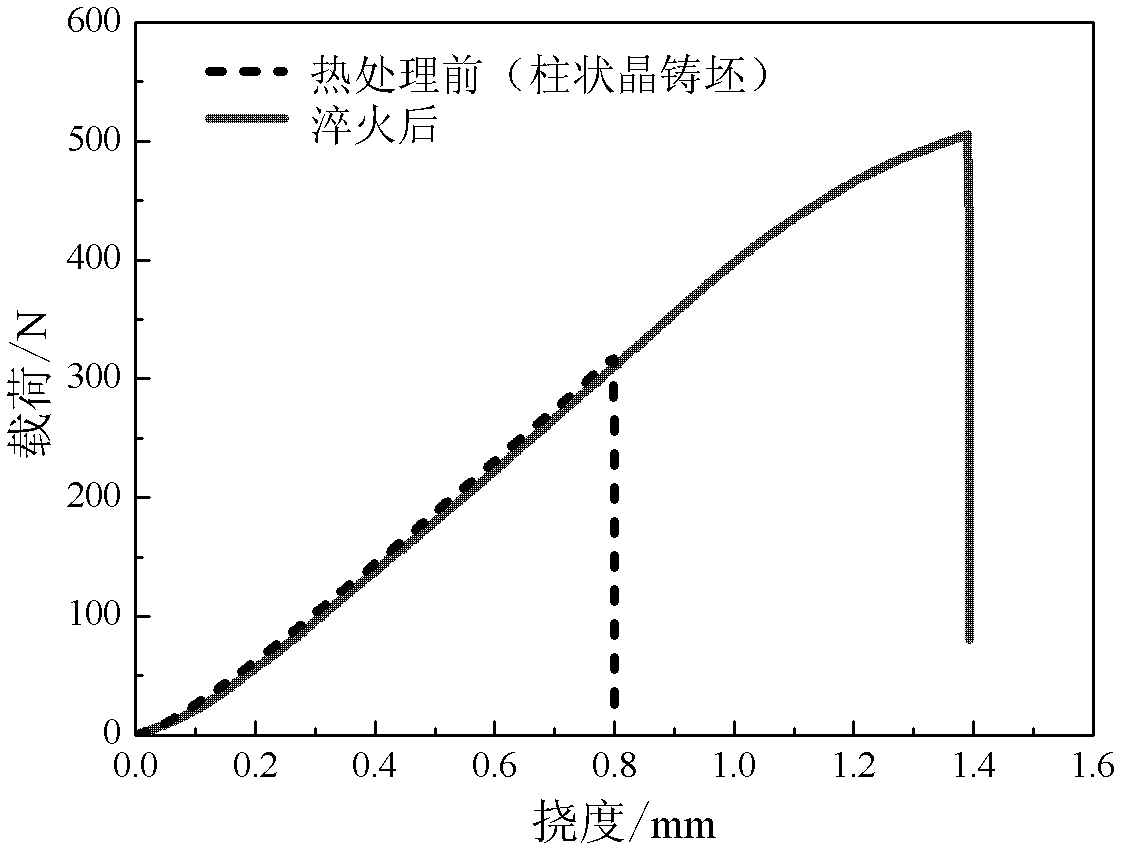

[0024] Example 1: Effect of heat treatment on bending mechanical properties of columnar high-silicon electrical steel slab at room temperature

[0025] Wire cutting and grinding the directional solidified columnar high-silicon electrical steel (Fe-6.52Si-0.05B) billet into 2×5×35mm 3 The bulk sample was heated to 900°C at 15°C / min, then kept for 1h, and cooled by oil quenching method commonly used in engineering. The samples before and after quenching were subjected to a three-point bending mechanical performance test. The experimental standard was in accordance with GB / T 14452-93. The changes in the measured bending mechanical properties were as follows: figure 2 shown. It can be seen that after quenching, the maximum bending stress of the sample increased by 45%, the fracture deflection increased by 74%, the bending fracture energy increased by 200%, and the plasticity at room temperature was significantly improved.

Embodiment 2

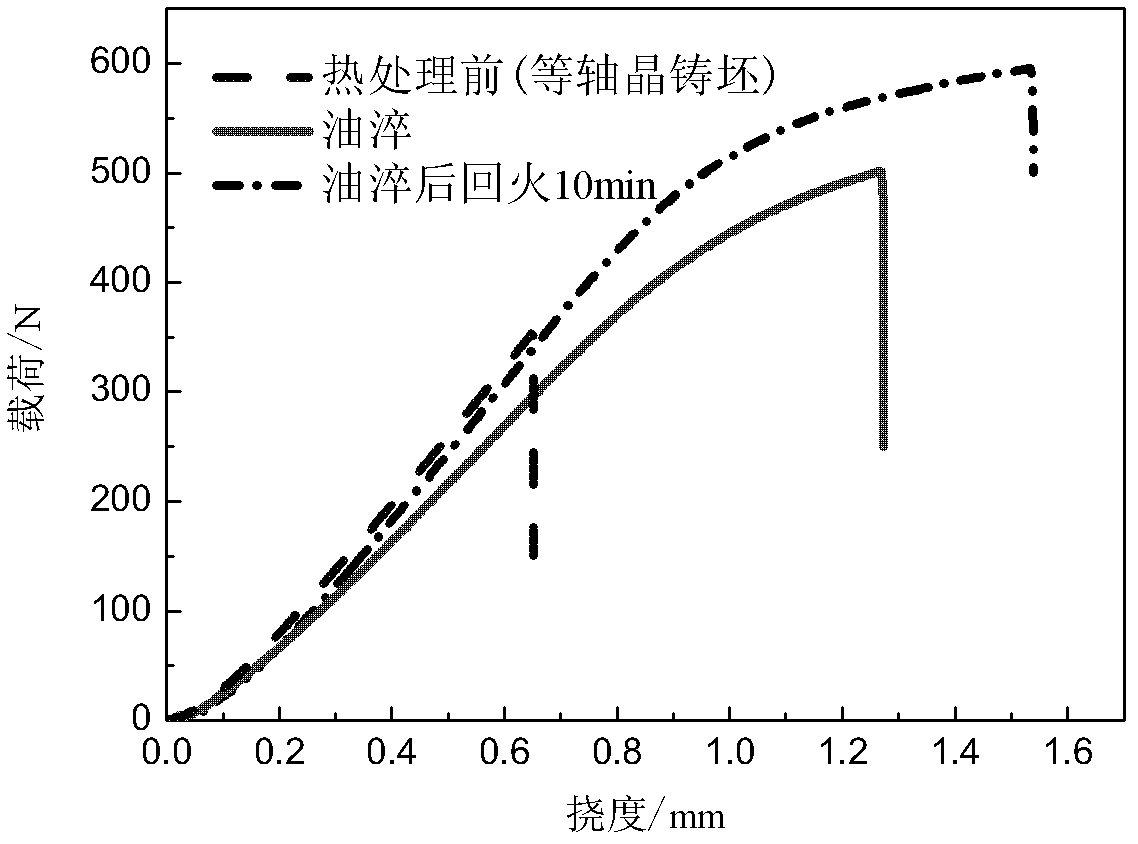

[0026] Example 2: Effect of heat treatment on bending mechanical properties of equiaxed as-cast high-silicon electrical steel at room temperature

[0027] The high-silicon electrical steel (Fe-6.47Si-0.01B) casting slab with equiaxed grain structure prepared by vacuum melting was wire-cut and ground into 2×5×35mm 3 The block sample was heated at 25°C / min to 1100°C and held for 1 hour, then oil quenched (cooling rate 74°C / s), and the cooled sample was annealed at 400°C for 10 minutes to reduce the quenching residue stress. The annealed sample was subjected to a three-point bending mechanical property test. The experimental standard was in accordance with GB / T 14452-93. The measured bending mechanical properties were as follows: image 3 shown. It can be seen that the average fracture deflection of the oil-quenched sample is 1.27mm, which is 95% higher than that of the cast state; the average fracture deflection of the sample after stress relief annealing is 1.53mm, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com