Monitoring method of heating time and heating temperature of heating furnace

A heating time and heating temperature technology, applied in heat treatment furnaces, heat treatment process control, furnaces, etc., can solve the problems of long heating time, increase oxidation burning loss, affect the cost per ton of steel, etc., to reduce the oxidation burning loss rate, The effect of preventing oxidation burning and reducing the cost per ton of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below by embodiment.

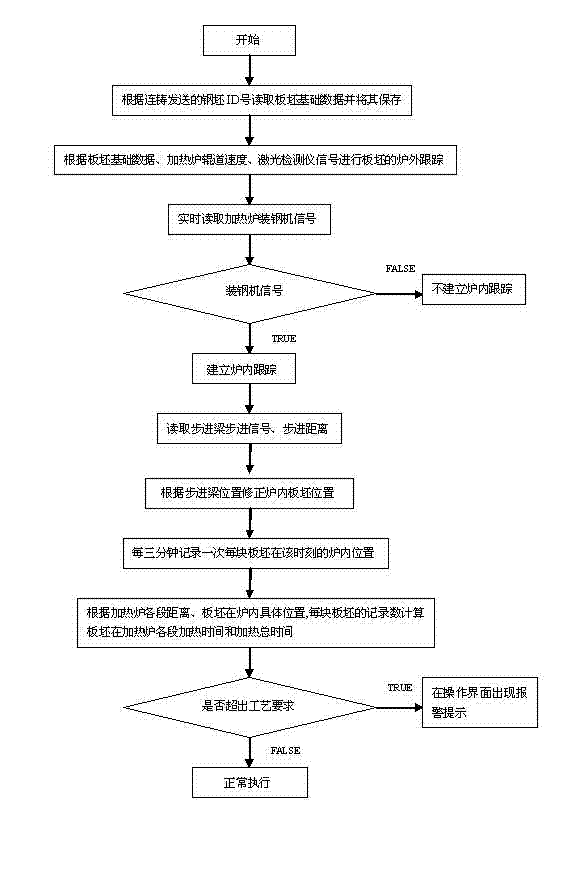

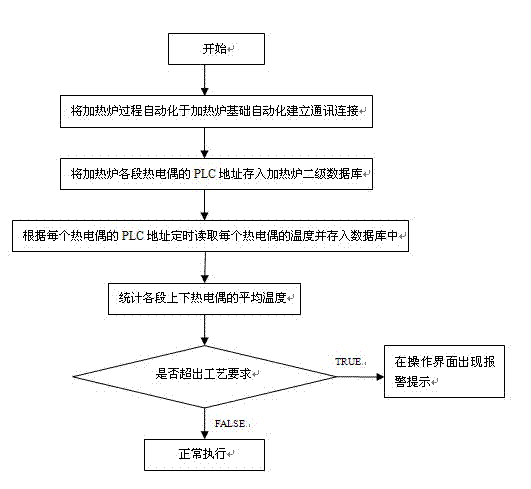

[0027] refer to figure 1 , the heating furnace heating time monitoring method comprises the following steps:

[0028] (1) The computer of the heating furnace process automation (heating furnace level 2) establishes a connection with the heating furnace basic automation (heating furnace level 1) PLC through OPC configuration, and uses the Visual Studio 2008 tool to write a program to read the continuous casting in real time and send it to the heating The billet ID number in the first-level PLC of the furnace (every time the continuous casting transfers a billet to the heating furnace, it will write down the ID number of the transferred billet to the first-level PLC of the heating furnace), and according to the ID number, go to the automation of the rolling line process (rolling line The basic data of the billet (including geometric dimensions, chemical composition, steel types, etc.) is read from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com