Metal strengthening heat transmission protection method in metal workpiece heating techniqiue

A heating process and metal strengthening technology, which is used in the field of metal material or workpiece heating to protect metal and strengthen heat transfer, so as to improve the output and productivity, reduce the loss rate, and increase the heating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

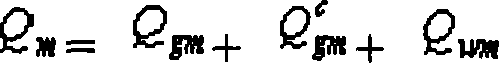

[0055] Referring to Fig. 2, the number in the figure: 1 is heating furnace No. 1, 2 is heating furnace No. 2, 3 is heating furnace No. 3, 4 is E1 vertical rolling mill, 5 is R1 rough rolling mill, 6 is E2 vertical rolling mill, 7 8 is the insulation cover, 8 is the flying shear, 9 is the vertical roll mill before finishing rolling, 10 is the finishing rolling unit, 11 is the laminar flow cooling device, 12 is the coiler, and 13 is the paint spraying machine system, thus forming a new production line process flow.

[0056] According to the method for protecting metal and strengthening heat transfer in the metal object heating process of the present invention, the metal material or workpiece heating process includes a heating furnace and a rolling line, and a paint spraying machine system is added before the heating furnace, and the metal heating process of the continuous casting process is: a. Straightening the metal billet; b. Cutting the metal billet; c. Coating the metal bil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com