Automatic control method and system device for adjustment on load of biogas supplied for steam boiler

An automatic control system and steam boiler technology, which is applied in the control system, steam generation, lighting and heating equipment, etc., can solve the problems that biomass gas is not suitable for boilers, so as to reduce the amount of human intervention, realize stable load changes, and ensure The effect of stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

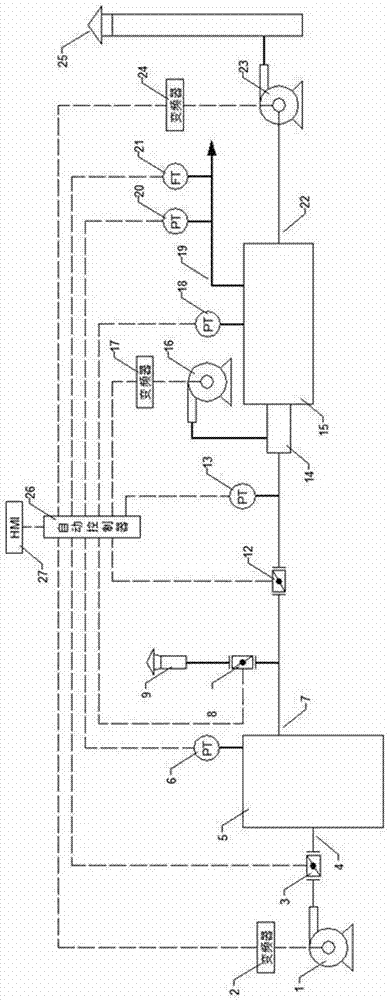

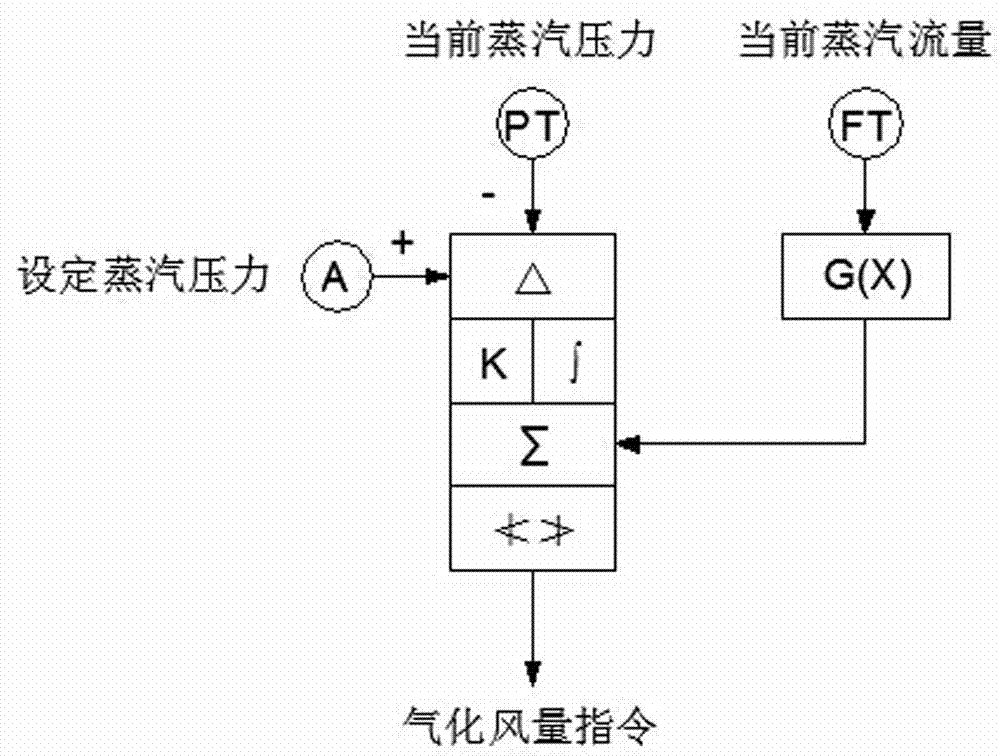

[0027] Such as figure 1 As shown, the gasification fan is an active regulating fan, and the other fans are passive regulating fans. The core of load control is the given method of the gasification air volume command. Under the normal working conditions of biomass gasifier and steam boiler, the gasification air volume basically determines the gas output of the gasifier, and the gas volume determines the steam output, so it can be considered that controlling the gasification air volume is equivalent to controlling the gas volume , the steam output can be controlled by controlling the gasification air volume, see image 3 , a given formula for gasification instructions is listed. The following is the control method of the driven regulating fan: the oxygen distribution fan of the burner is controlled according to the calibration value of the oxygen distribution amount and the gasification air volume, following the gasification air volume command, and the control goal is to ensur...

Embodiment 2

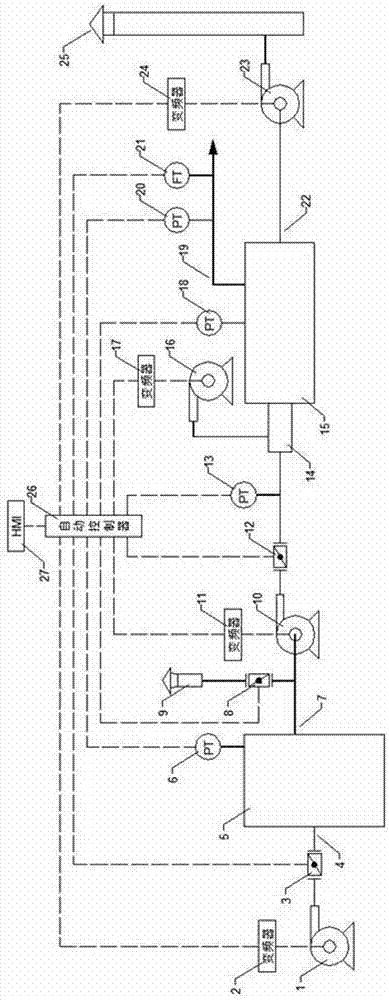

[0031] Such as figure 2 , In this embodiment, on the basis of Embodiment 1, a gas induced draft fan and a gas induced draft fan frequency converter are installed at the front end of the burner. In this embodiment, the gasification fan is used as an active regulating fan, and the other fans are all driven regulating fans. The core of load control is the method of setting the gasification air volume command. The gas induced draft fan is used as a driven regulating fan, and the gas induced draft fan is regulated by the gasification air volume command and the gas pressure value of the furnace top. The driven fan is the same as in Embodiment 1.

Embodiment 3

[0033] Such as figure 2 As shown, in this embodiment, the gas-fired induced draft fan is used as the active regulating fan, and the other fans are all driven regulating fans. The core of load control is the given method of gas quantity command. Under the normal working condition of biomass gasifier and steam boiler, the amount of gas determines the steam output, and the steam output can be controlled by controlling the amount of gas. Figure 4 A given formula of gas quantity command is listed. The following is the control method of the driven regulating fan: the gasification fan is adjusted according to the gas volume command and the pressure value of the furnace top gas. The control method of the oxygen distribution fan and the flue gas induced draft fan is similar to that of Example 1. The oxygen distribution fan of the burner is controlled according to the calibration value of the oxygen distribution amount and the gas volume, following the gas volume command; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com