High-temperature dust-containing flue gas moving particle bed purification and waste heat recovery system

A technology of waste heat recovery system and moving particle bed, which is applied in the direction of dispersed particle filtration, heat exchanger, gas treatment, etc., can solve the problem of lack of purification and heat exchange technology of high-temperature dusty flue gas containing condensable dust particles, lack of high-temperature flue gas Deep purification and heat exchange integrated integration technology, limited heat exchange specific surface area and other issues, to achieve the effect of simple structure, high waste heat recovery rate, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

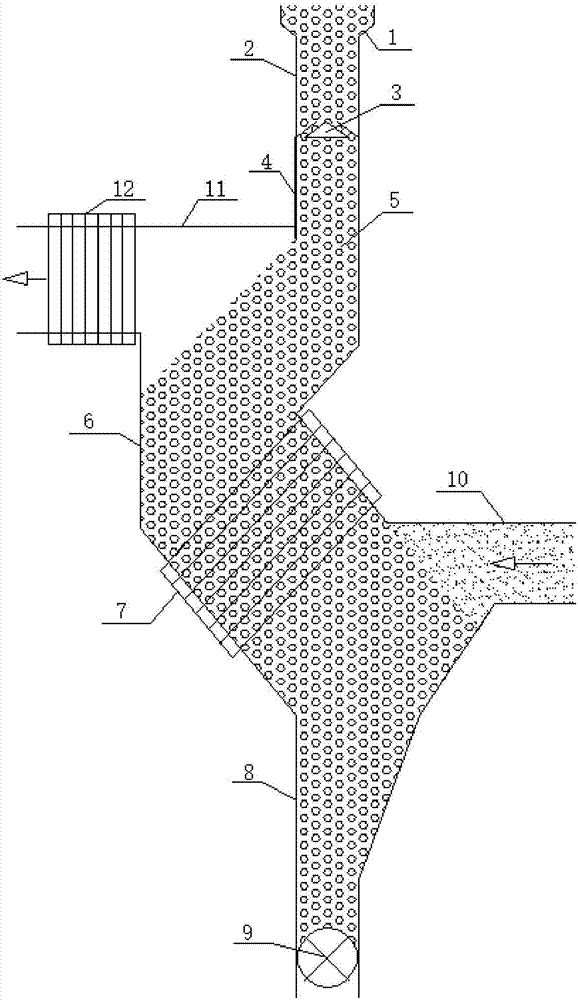

[0034] like figure 1 As shown, the embodiment of the present invention is a high-temperature dust-laden flue gas moving particle bed purification and waste heat recovery system. The high-temperature dust-laden flue gas moving particle bed purification and waste heat recovery system includes: feed channel 2, filter channel 6, discharge channel Channel 8, flue gas inlet channel 10, flue gas outlet channel 11, primary heat exchanger 7 and secondary heat exchanger 12, the top of the feed channel 2 is provided with a filter particle inlet 1, the bottom of the feed channel 2 is connected to the filter channel 6 is connected to the top, and the bottom of the filter channel 6 is connected to the top of the discharge channel 8; a primary heat exchanger 7 is arranged inside the filter channel 6; the flue gas inlet channel 10 and the flue gas outlet channel 11 are arranged in the horizontal direction, and the feed channel 2, The discharge channel 8 is arranged in the vertical direction. ...

Embodiment 2

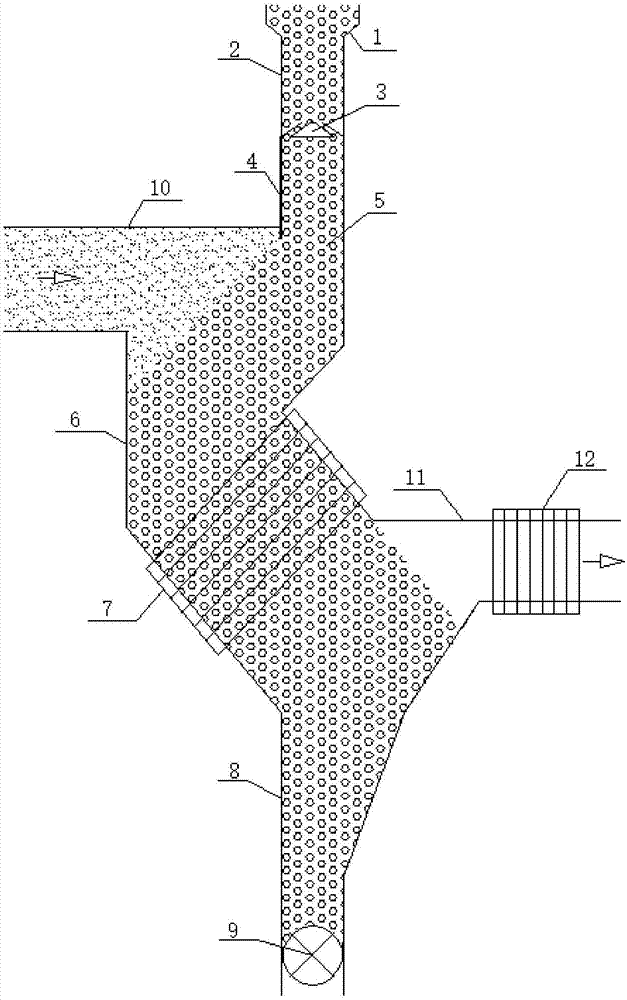

[0046] like figure 2 As shown, the embodiment 2 of the present invention provides a high-temperature dusty flue gas moving particle bed purification and waste heat recovery system. In the filter channel, the flow direction of the flue gas is the same as that of the particles, and the figure 1 The direction of flue gas flow in the middle is opposite to the direction of particle flow.

[0047] The following is a specific description of the high-temperature dust-laden flue gas moving particle bed purification and waste heat recovery system provided by the present invention with examples.

[0048] Build a set of high-temperature dusty flue gas mobile particle bed purification and waste heat recovery integrated experimental platform, including feed channel, filter channel, discharge channel, flue gas inlet channel, flue gas outlet channel, and a primary heat exchanger.

[0049] The cross-sectional size of the feed channel and the discharge channel is 100mm×100mm square structure, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com