Camphorwood vaporization water vapor drying and essential oil and waste heat recycling device and using method

A waste heat recovery device and waste heat recovery technology, which are applied in the directions of wood drying, drying gas arrangement, drying solid materials, etc., can solve the problems of difficulty in extracting essential oils, long drying time, and pollution of the environment by exhaust gas emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

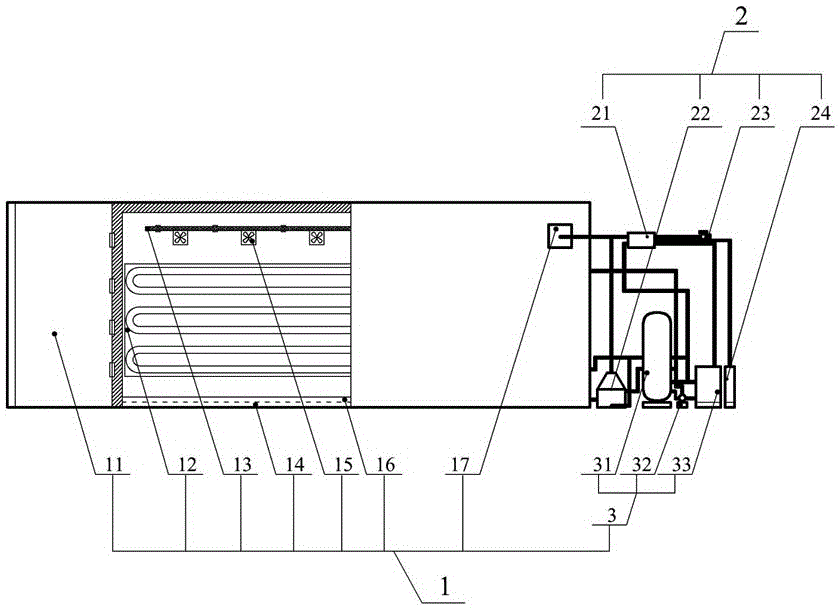

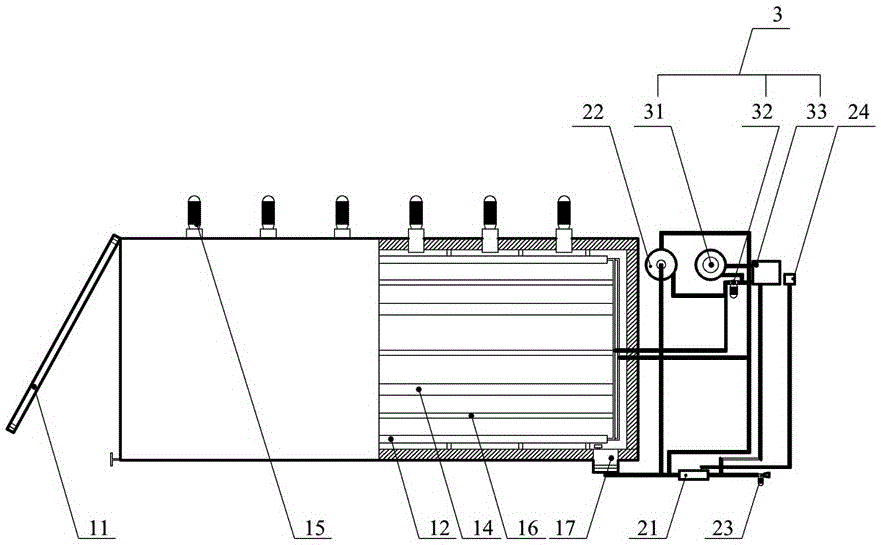

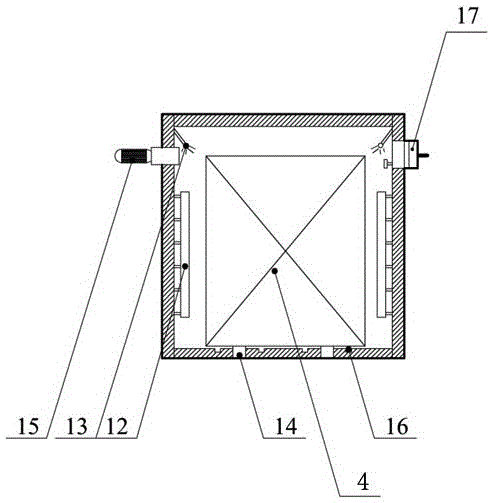

[0031] Figure 1 to Figure 6 It shows an embodiment of camphor wood vaporization steam drying and essential oil and waste heat recovery device of the present invention, the device includes a high-temperature drying chamber 1, an essential oil and waste heat recovery assembly 2 and a heat source assembly 3, and the front end of the high-temperature drying chamber 1 is provided with a The drying chamber door 11 that the camphor wood pile material 4 enters, the high temperature drying chamber 1 is provided with a cooling fin assembly 12 and a steam spray assembly 13 positioned at both sides of the camphor wood pile material 4, and the bottom of the high temperature drying chamber 1 is provided with a The bottom rail 14 of the material 4 and the condensed water recovery channel 16 for recovering condensed water. The high-temperature dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com