Silicon smelting electric furnace waste heat power generation process flow and configuration

A technology for waste heat power generation and process flow. It is applied in lighting and heating equipment, mechanical equipment, and process efficiency improvement. It can solve the problems of immature flue gas extraction technology, high failure rate of heat exchangers, and fluctuation of waste heat. The effect of small leakage of cold air, improving the utilization rate of waste heat and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

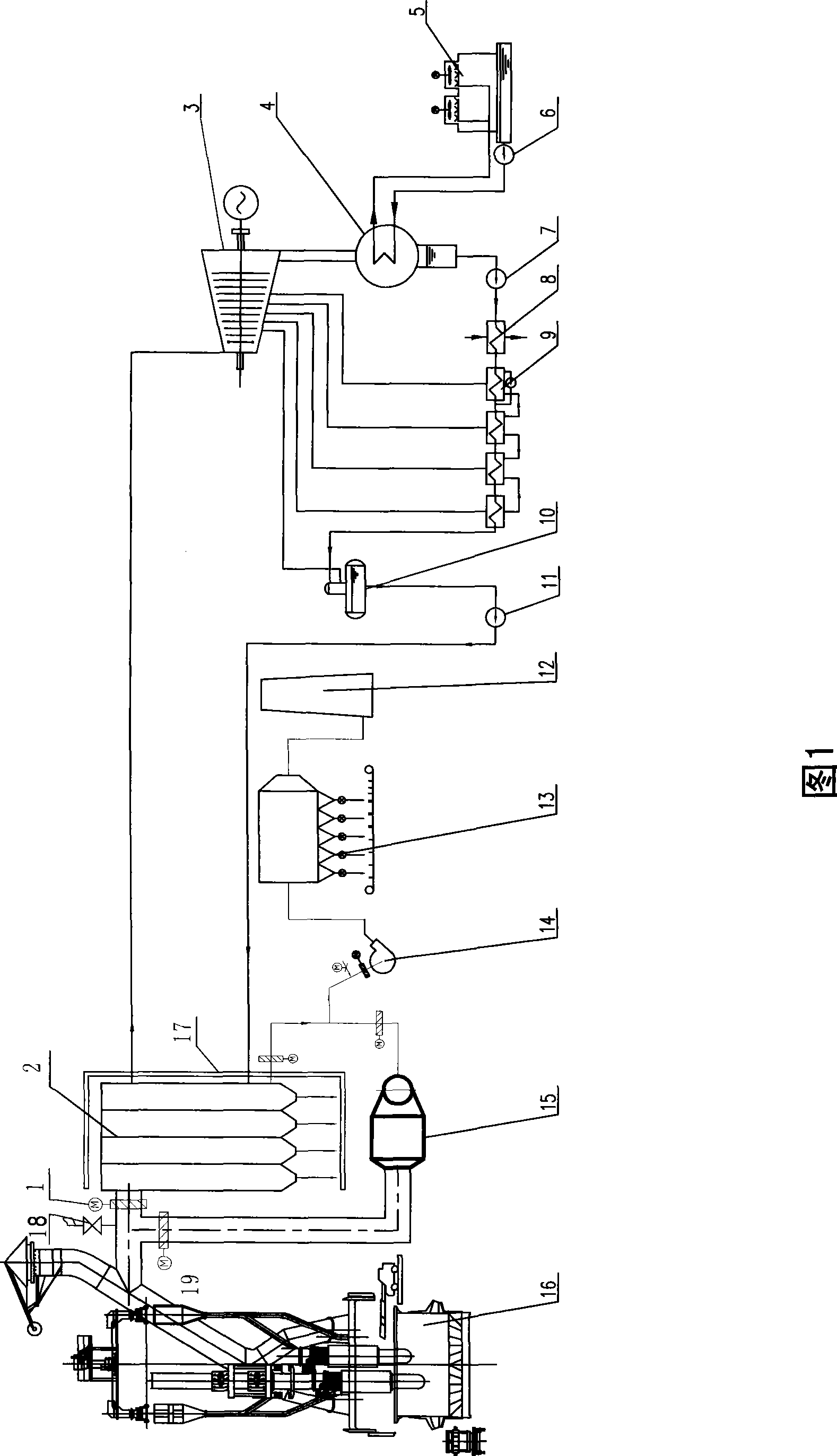

[0031] The waste heat power generation process of the silicon smelting electric furnace of the present invention is that the waste gas discharged from the top of the silicon smelting electric furnace is collected through a semi-closed smoke hood and introduced into the waste heat boiler through the pipeline. The superheated steam generated by the waste heat boiler enters the turbogenerator unit through the main steam valve to generate electricity, and the exhaust steam at the tail is cooled in the condenser by a circulating water system composed of a cooling tower and a circulating water pump. It is condensed water, and the condensed water enters the thermal deaerator after being heated by the condensate pump, steam seal heater and several low-pressure heaters. The steam extraction in the boiler heats the condensed water and desalinated water to about 104°C. After removing the oxygen in the water, it is pressurized by the feed water pump and enters the waste heat boiler. The fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com