Patents

Literature

40results about How to "Increase waste heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

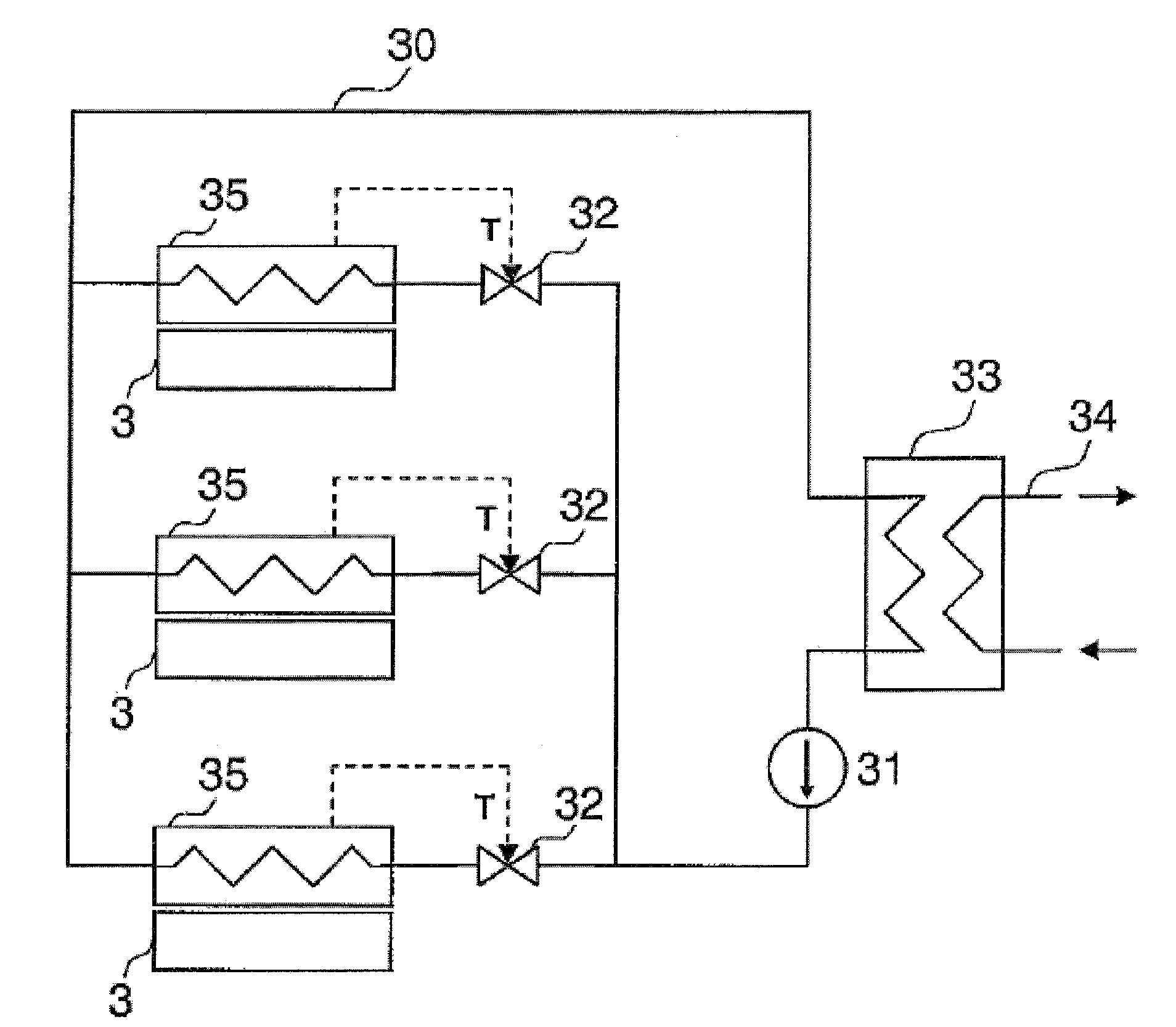

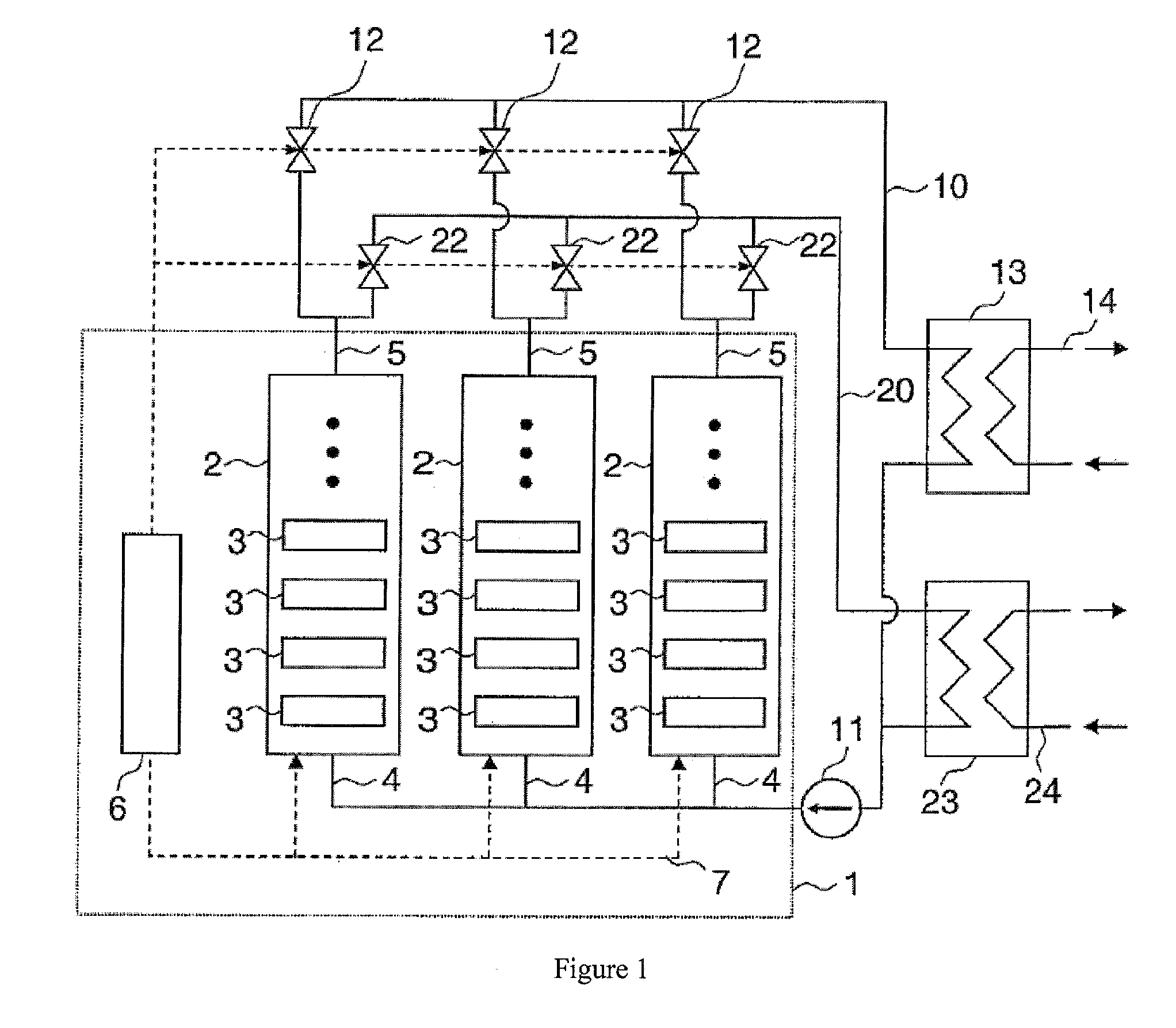

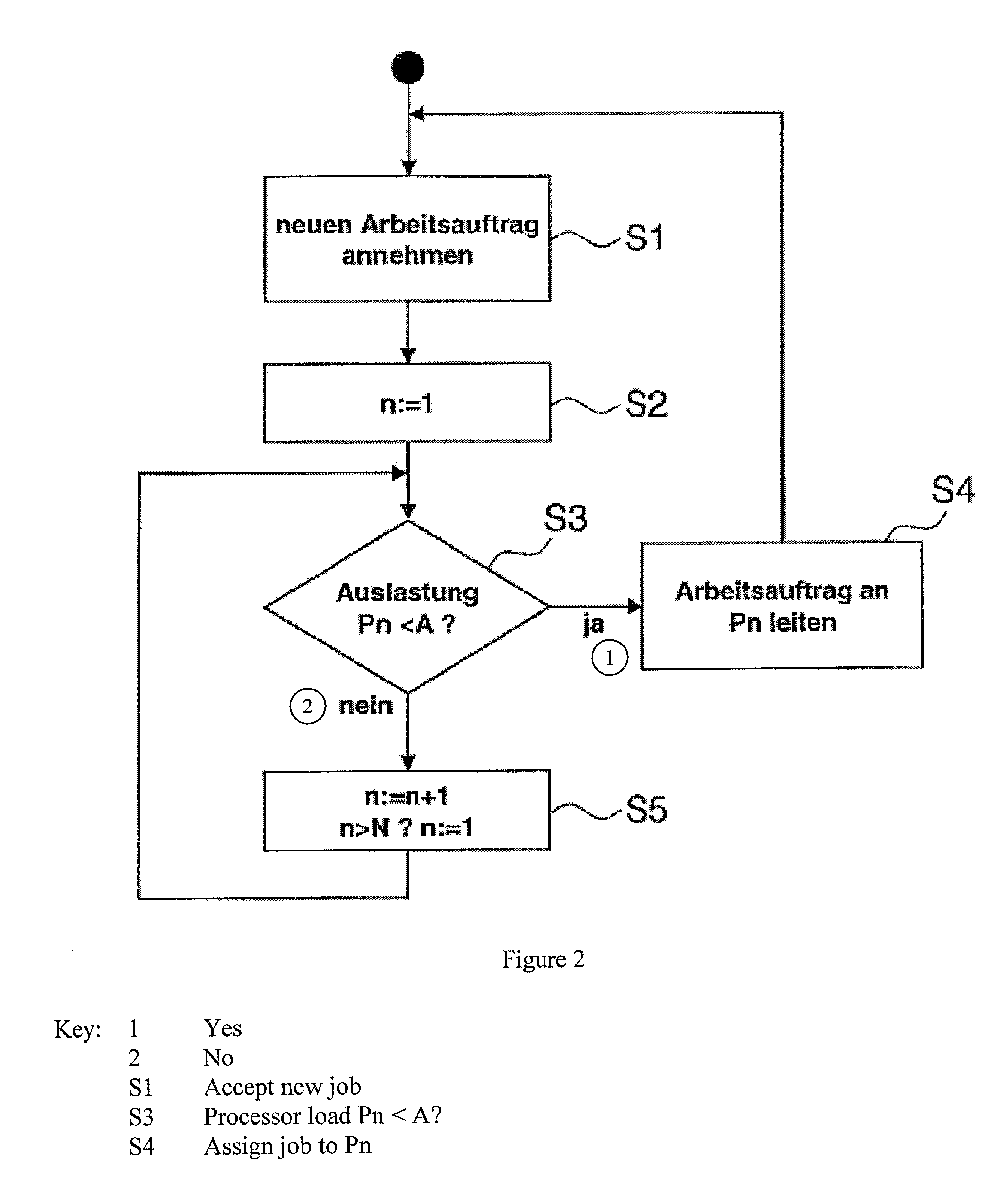

Method and system for using the waste heat of a computer system

InactiveUS20090114370A1Improve efficiencyUse waste heatDigital data processing detailsAir heatersComputerized systemWaste heat

A method for using the waste heat of a computer system with a plurality of processors comprises the following steps. Jobs in the computer system are distributed to the processors in such a way that processors of a first group of processors are operated with a high processor load and processors of a second group of processors are operated with only a minimal processor load. In another method, waste heat is dissipated from the processors by a cooling device, wherein the waste heat dissipated from the processors is regulated in such a way that the processor assumes a temperature that is greater than a given minimum temperature. In both cases, the waste heat of the processors is transferred to a device for using the waste heat.

Owner:KONIG CHRISTOPH

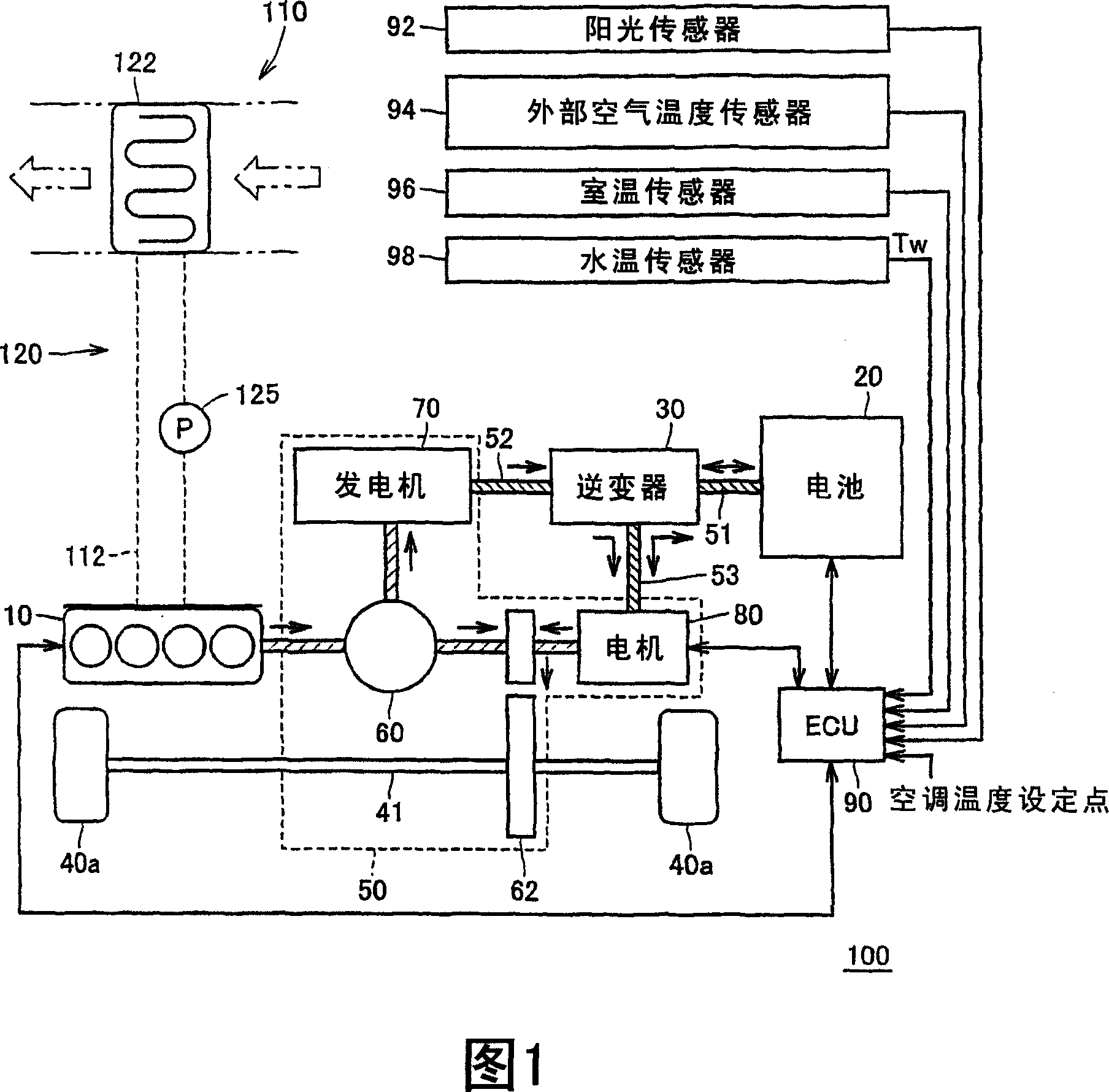

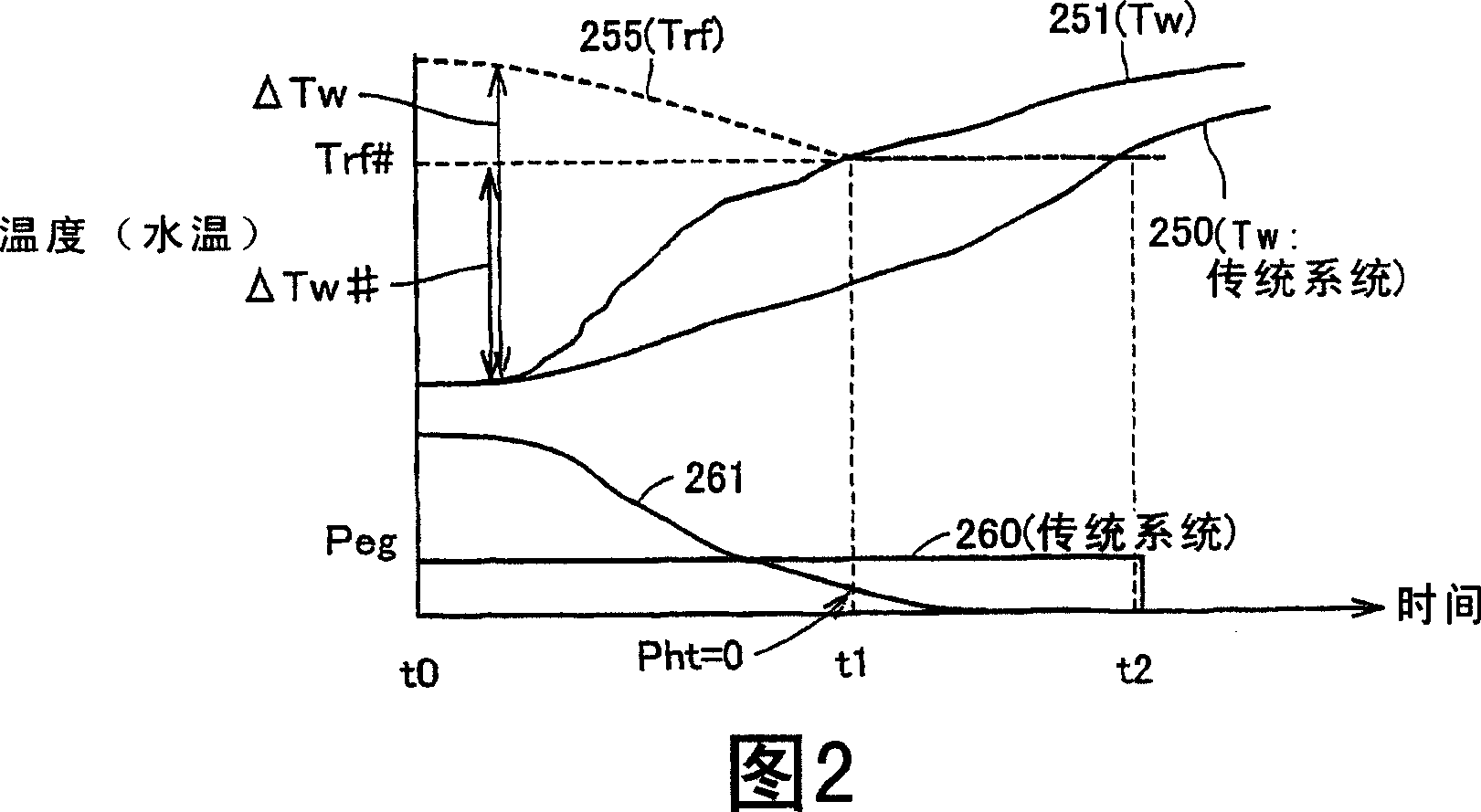

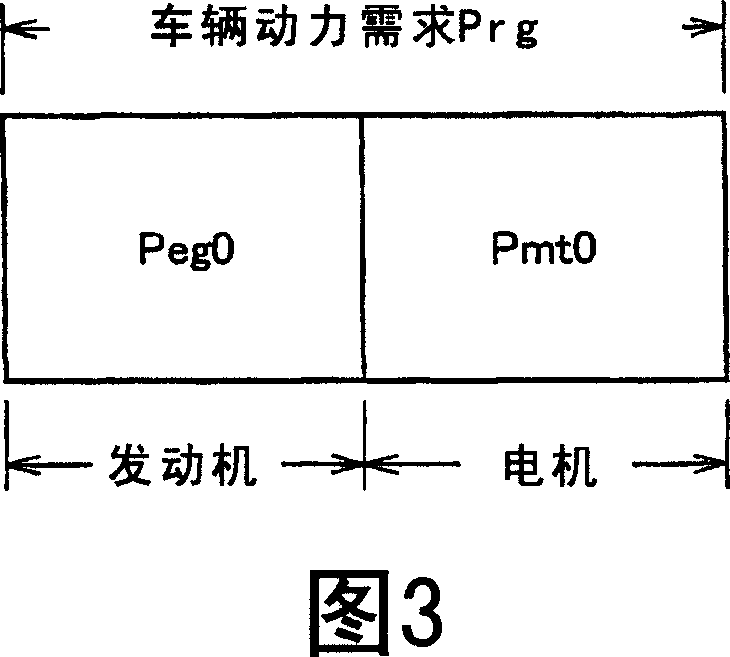

Heating control system for vehicle

InactiveCN1950223AImprove economyIncrease temperatureHybrid vehiclesAir-treating devicesThermal energyEngine efficiency

A hybrid vehicle can be driven using both of respective driving forces from an engine and a motor. A heating mechanism of an air conditioning apparatus uses thermal energy from cooling water of the engine to heat the interior of a passenger compartment. An ECU takes into consideration engine efficiency from the standpoint of fuel economy enhancement to primarily determine the driving force share ratio between the engine and the motor. Further, the ECU calculates a preset temperature corresponding to a cooling water temperature necessary for desired heating as well as a control target temperature in which the preset temperature is reflected, and corrects the primarily determined driving force share ratio to increase the share of the driving force of the engine by an amount according to a deviation between the cooling water temperature measured by a water temperature sensor and the control target temperature. Heating performance can thus be ensured promptly without deterioration of fuel economy.

Owner:TOYOTA JIDOSHA KK

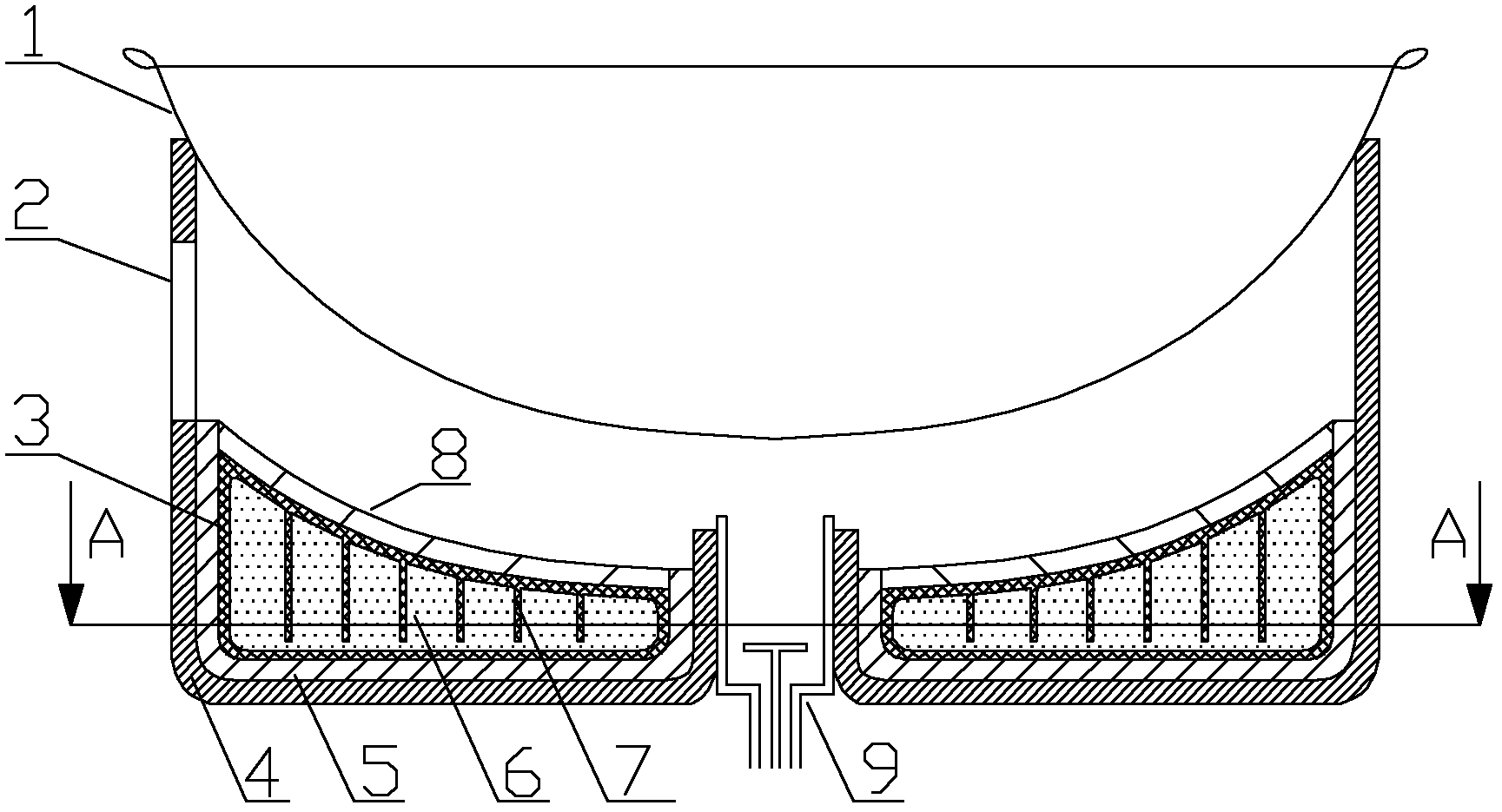

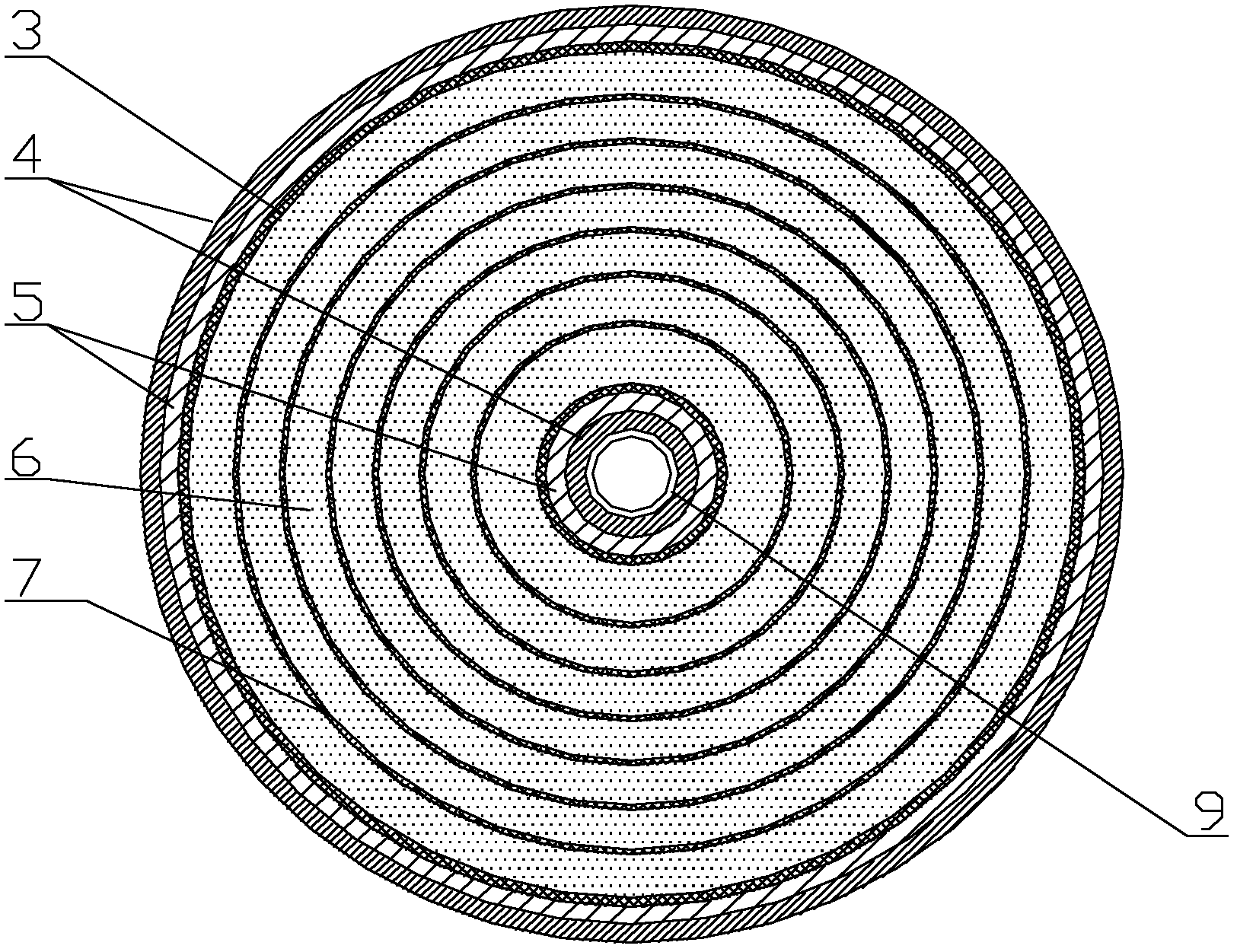

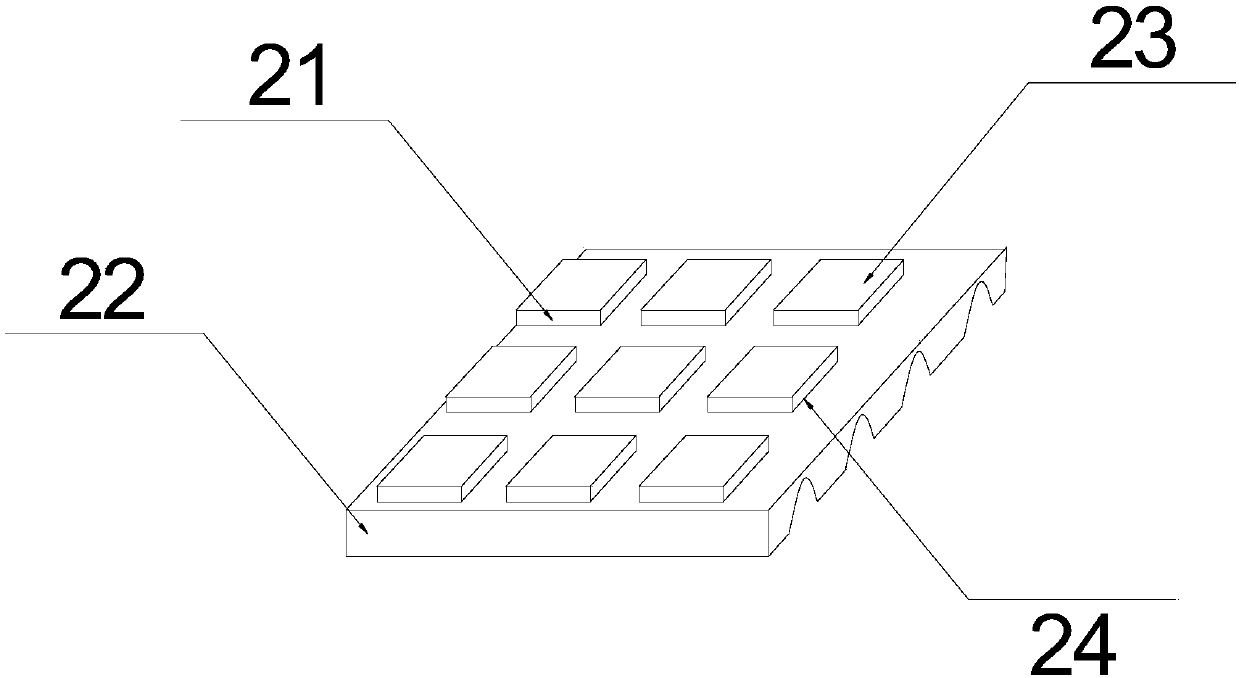

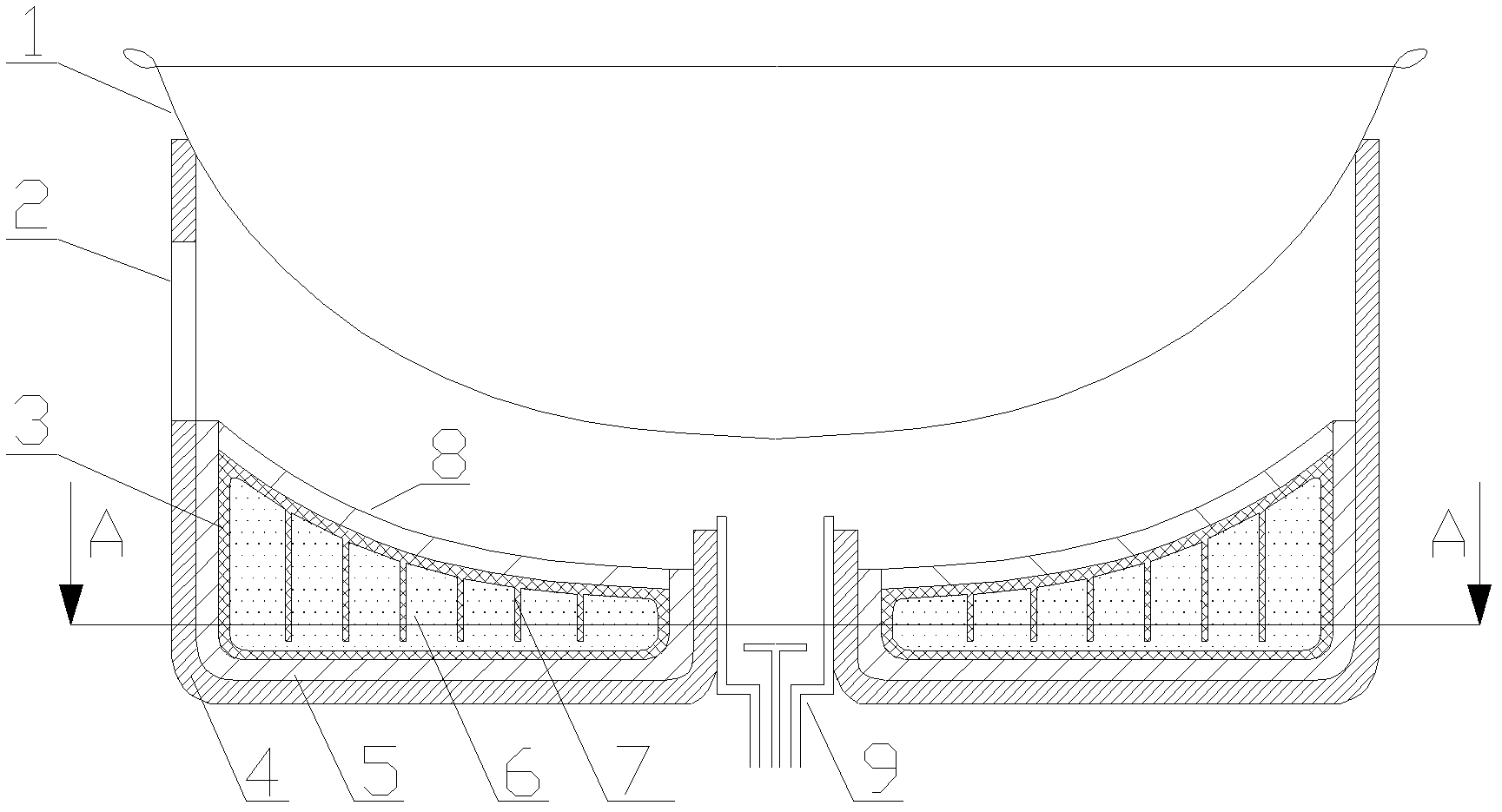

Energy-saving gas stove

ActiveCN102620321AIncrease profitImprove gas utilizationDomestic stoves or rangesLighting and heating apparatusEngineeringPhase change

The invention discloses an energy-saving gas stove which comprises an energy collecting cavity, a stove wall, a phase change heat accumulator, ribs, an infrared radiation ceramic plate and a gas stove head, wherein the stove wall is of an opening cavity structure; the upper end of an opening is used for holding cookware; the gas stove head is arranged in the opening at the bottom center of the stove wall; the energy collecting cavity is arranged at the lower end in the stove wall cavity and is of a cylindrical cavity structure; the upper surface of the energy collecting cavity is a pot-shaped curved surface; a plurality of ribs are arranged between an upper bottom surface and a lower bottom surface in the cavity of the energy collecting cavity at intervals; the infrared radiation ceramic plate is attached to the upper surface of the energy collecting cavity; and the phase change heat accumulator is arranged in the energy collecting cavity. According to the energy-saving gas stove disclosed by the invention, the infrared radiation ceramic plate reflects and absorbs the heat which is not utilized by an iron pan and part of heat is transmitted to the energy collecting cavity for storing energy. When the energy collecting cavity releases the heat, the heat is transmitted to the infrared radiation ceramic plate and generates infrared radiation for heating the iron pan. According to the gas cooking stove disclosed by the invention, the heat energy utilization rate of the gas cooking stove is increased and the aim of saving energy is achieved.

Owner:GUANGDONG HENGLIAN FOOD MACHINERY

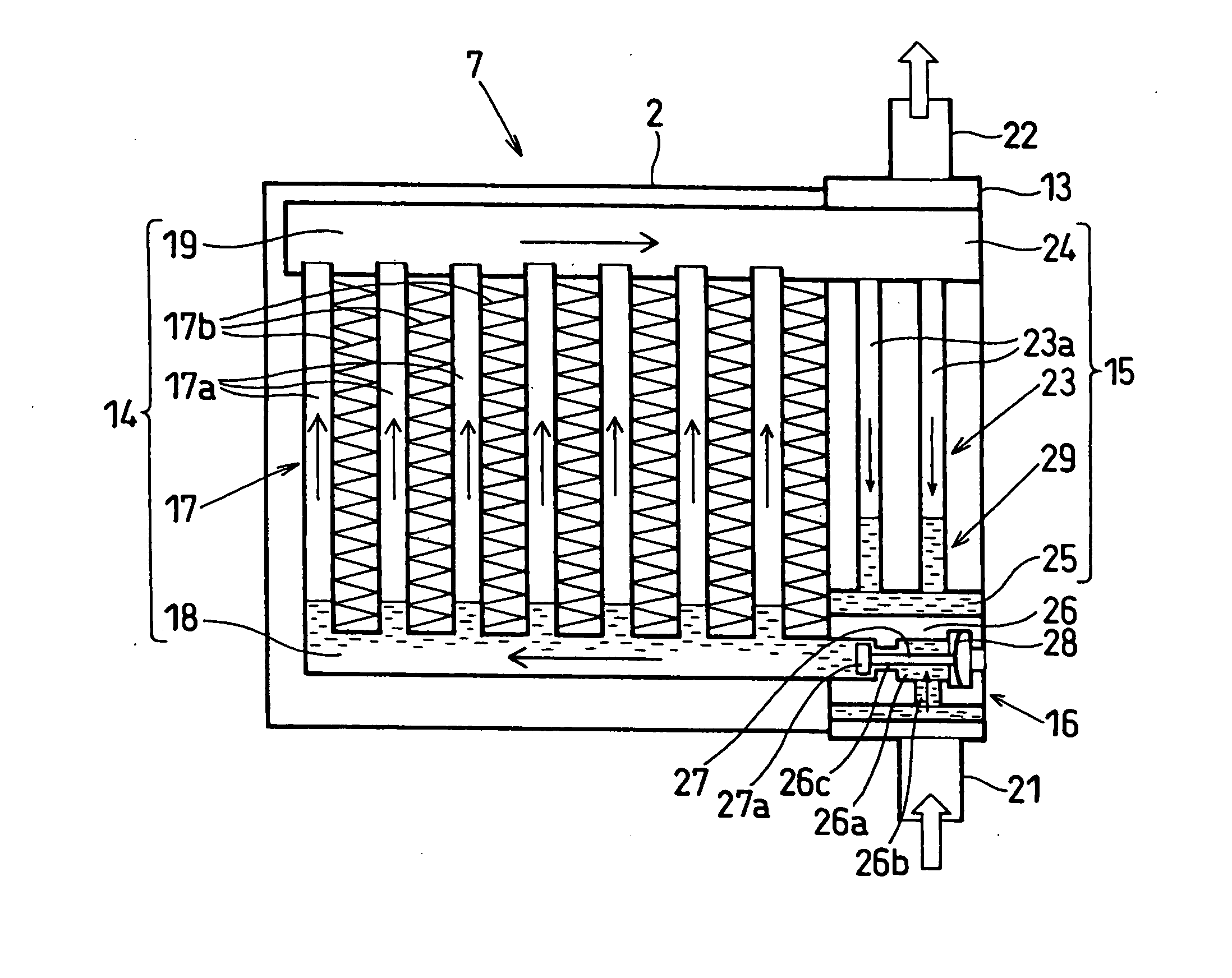

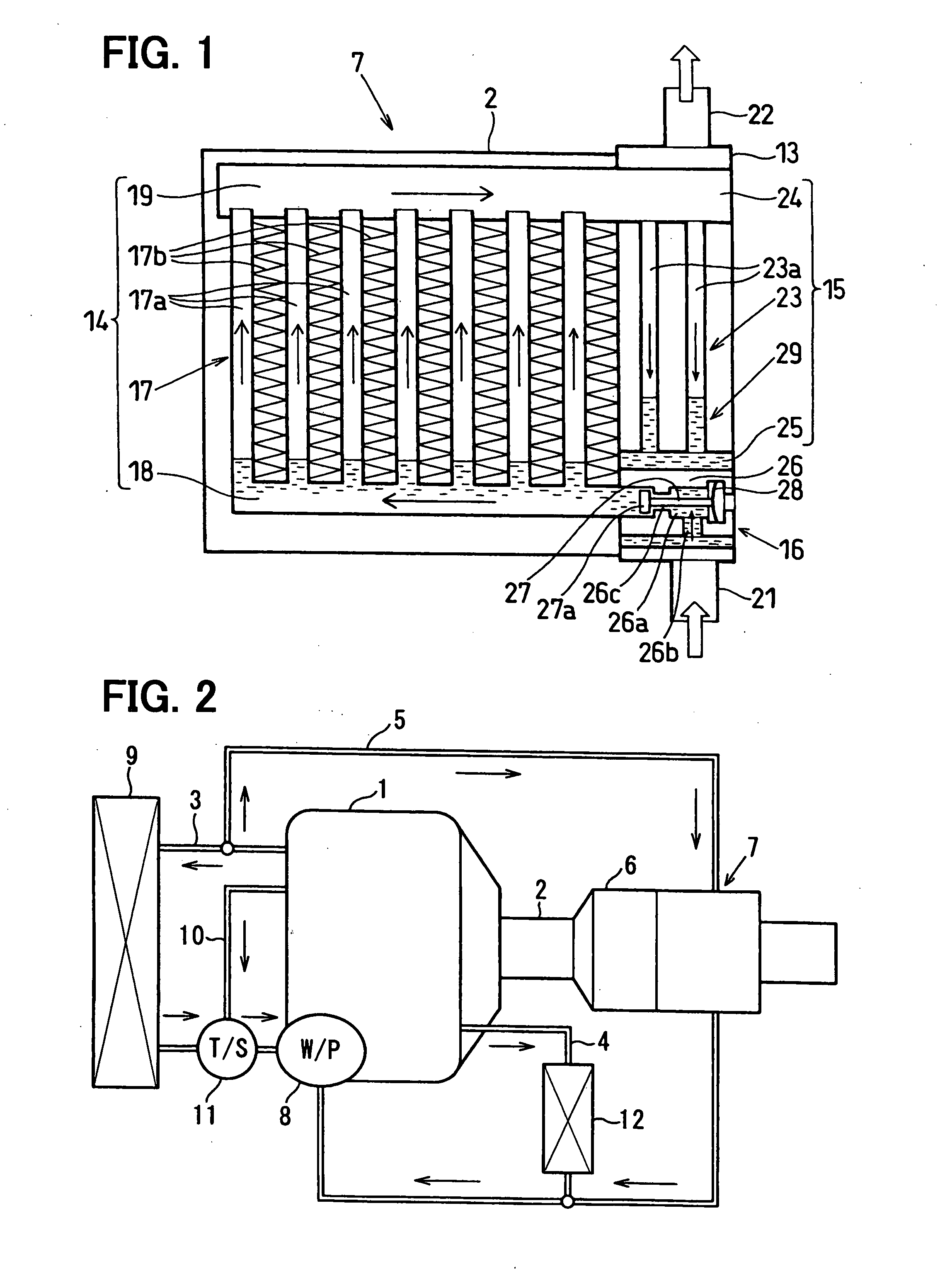

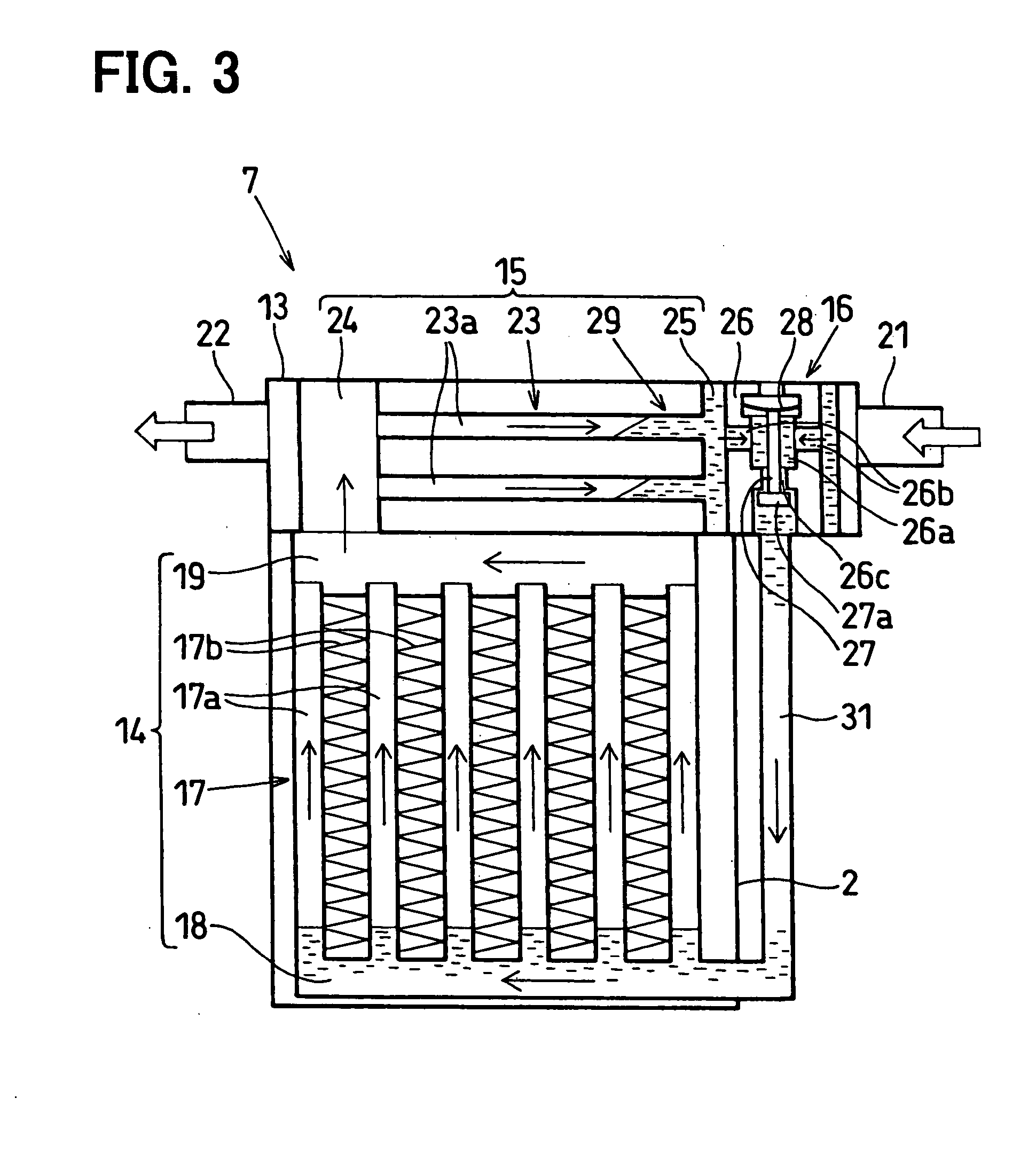

Loop type heat pipe and waste heat recovery device

InactiveUS20070289721A1Lower temperature of liquidIncrease waste heatRecuperative heat exchangersRefrigerantEvaporator

A loop type heat pipe includes an evaporator located to evaporate a refrigerant by heat-exchanging with a first fluid as a heat source, and a condenser located to liquefy and condense the evaporated vapor refrigerant by heat-exchanging with a second fluid to be heated. The condenser has a refrigerant condensation side on which the condensed liquid refrigerant flows, and a refrigerant un-condensation side on which the vapor refrigerant before being condensed flows. In addition, the loop type heat pipe is provided with a flow limitation portion for flowing the second fluid from the refrigerant condensation side toward the refrigerant un-condensation side. For example, the loop type heat pipe is suitably used for a waste heat recovery device.

Owner:DENSO CORP

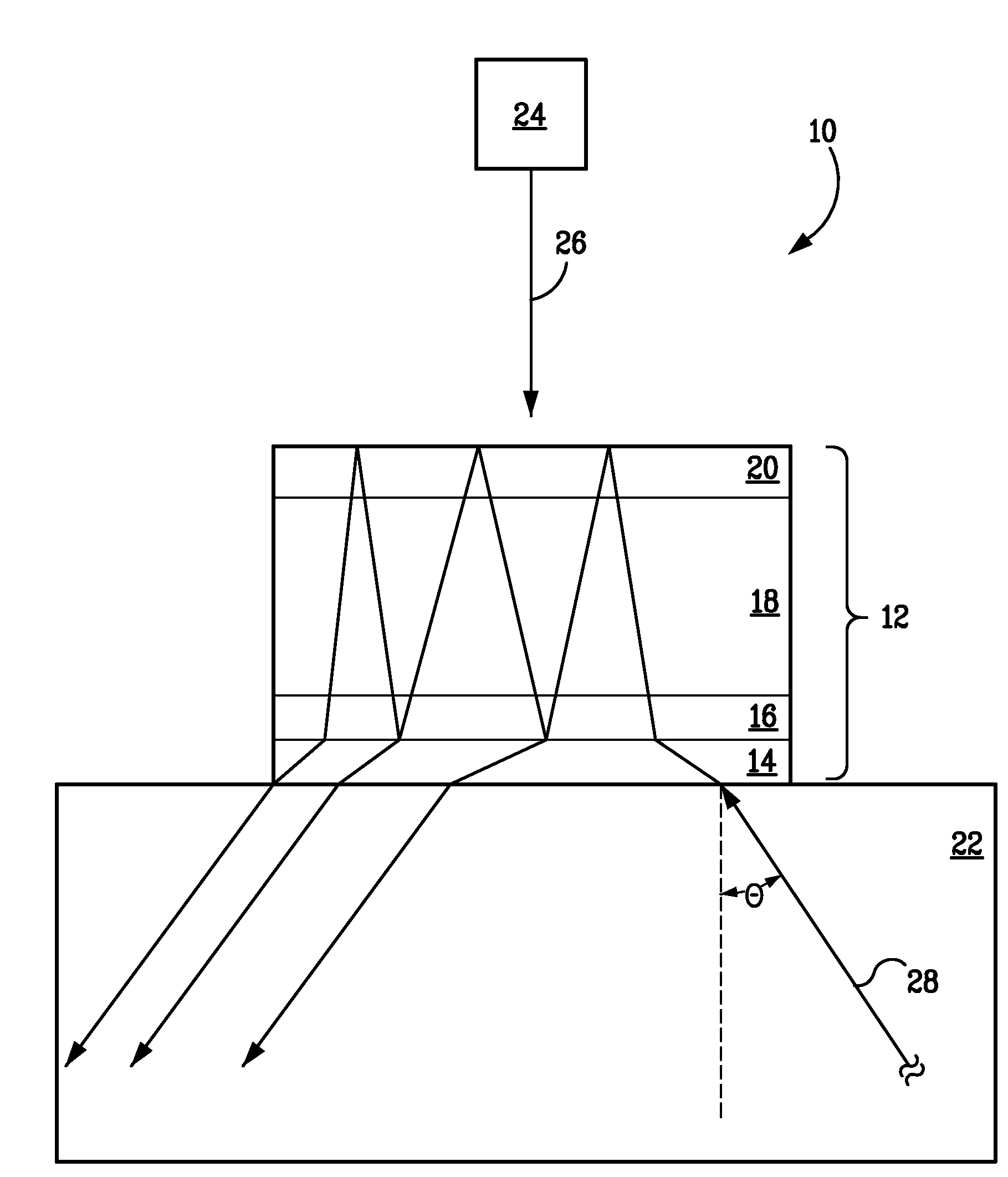

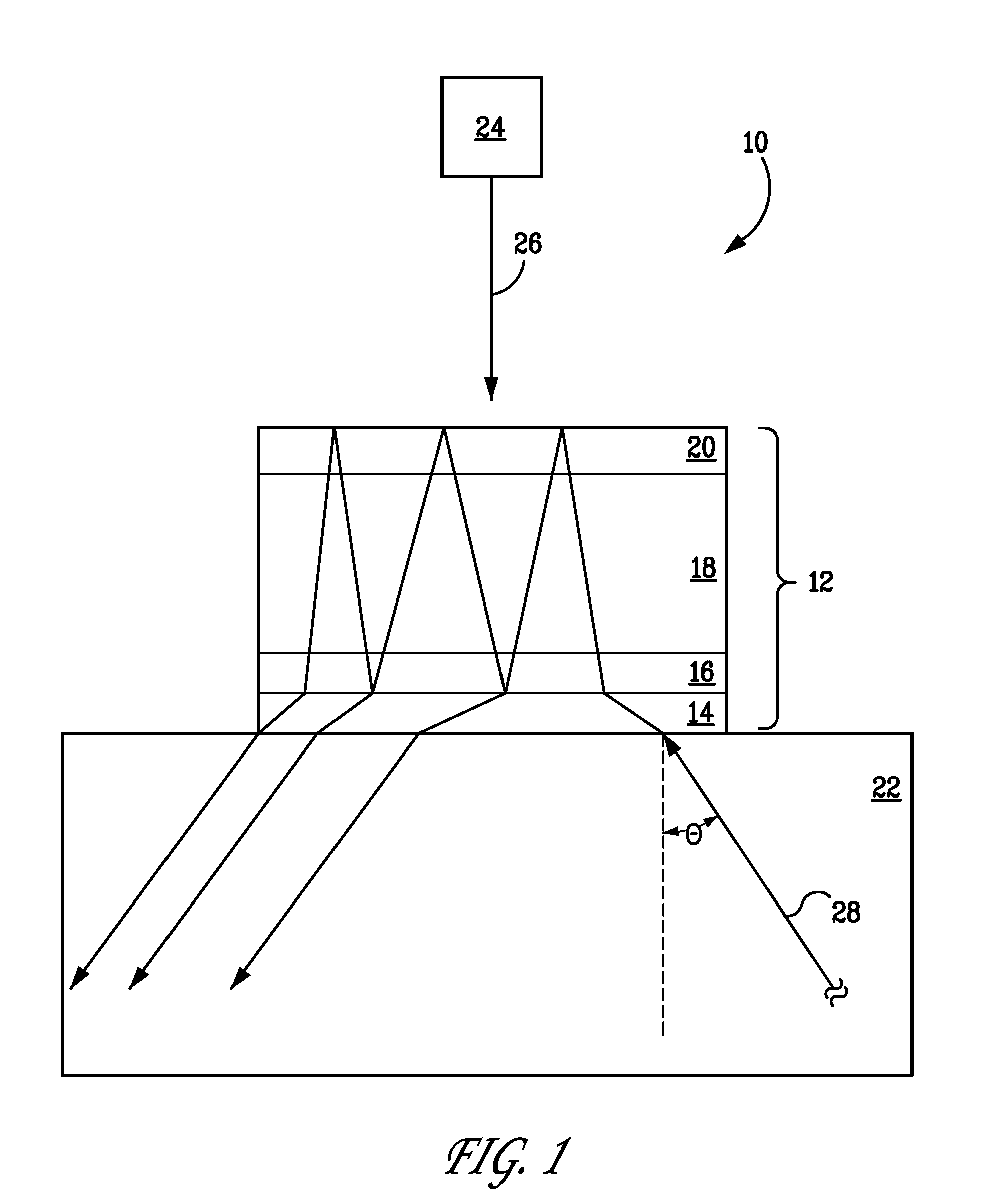

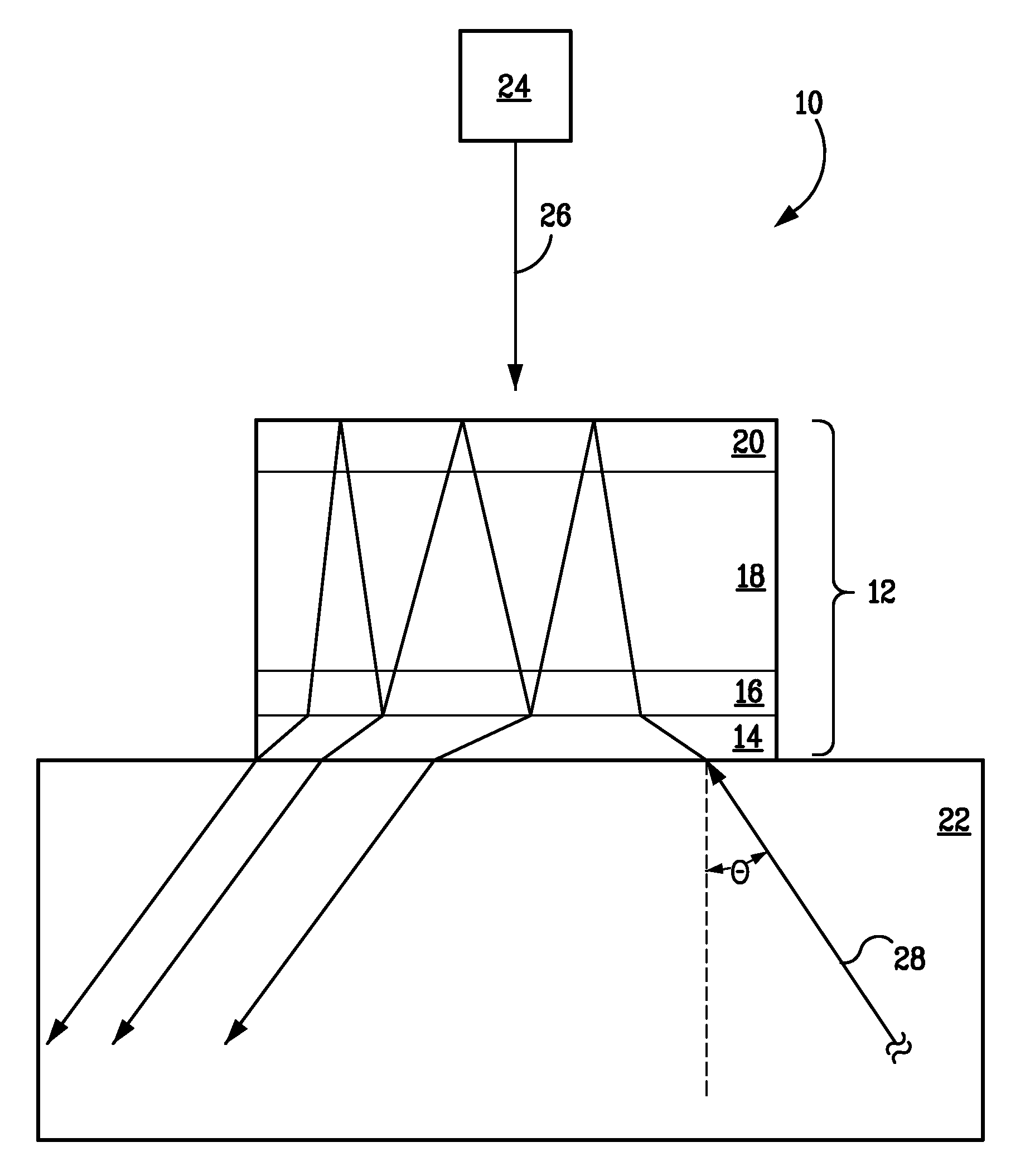

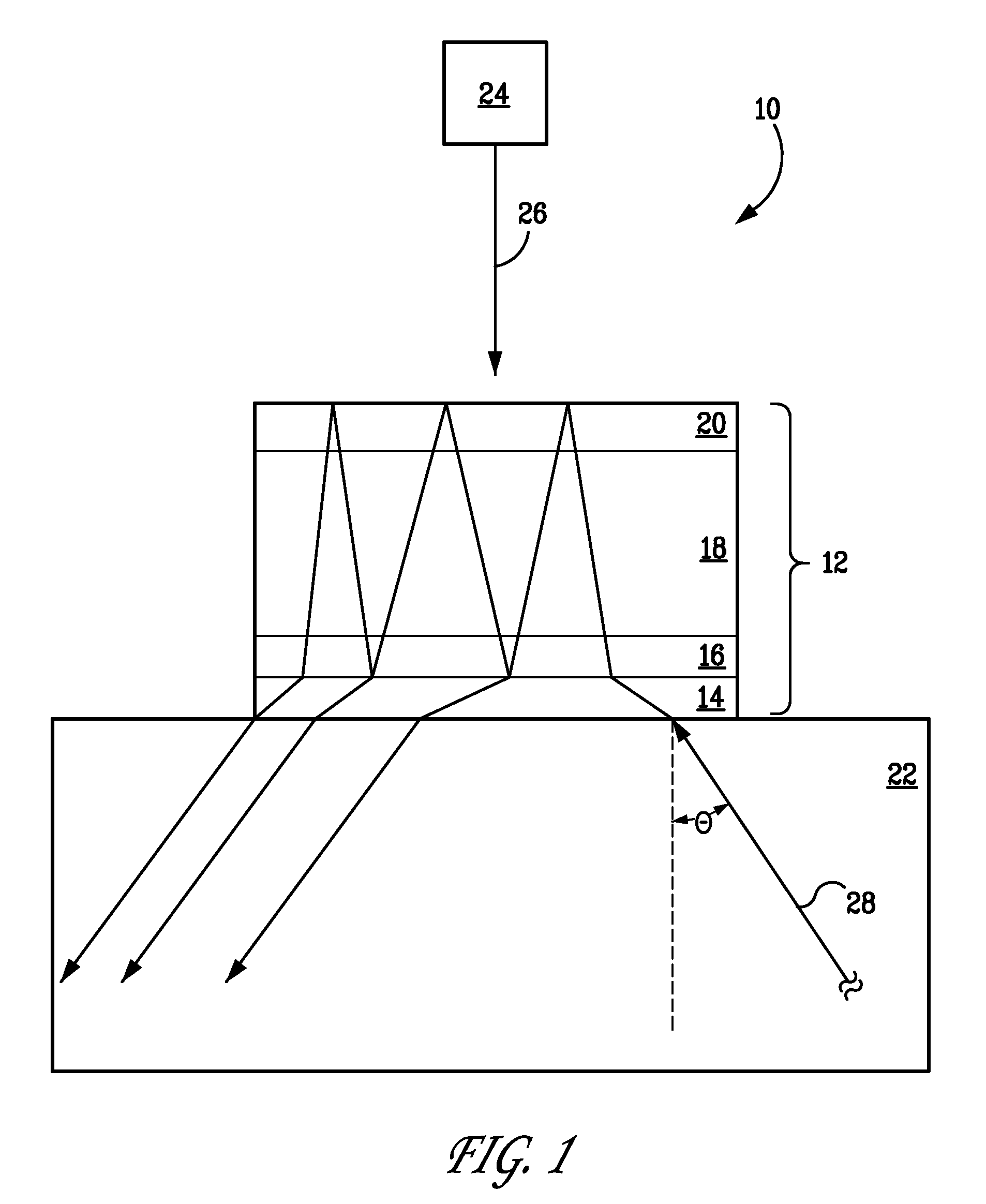

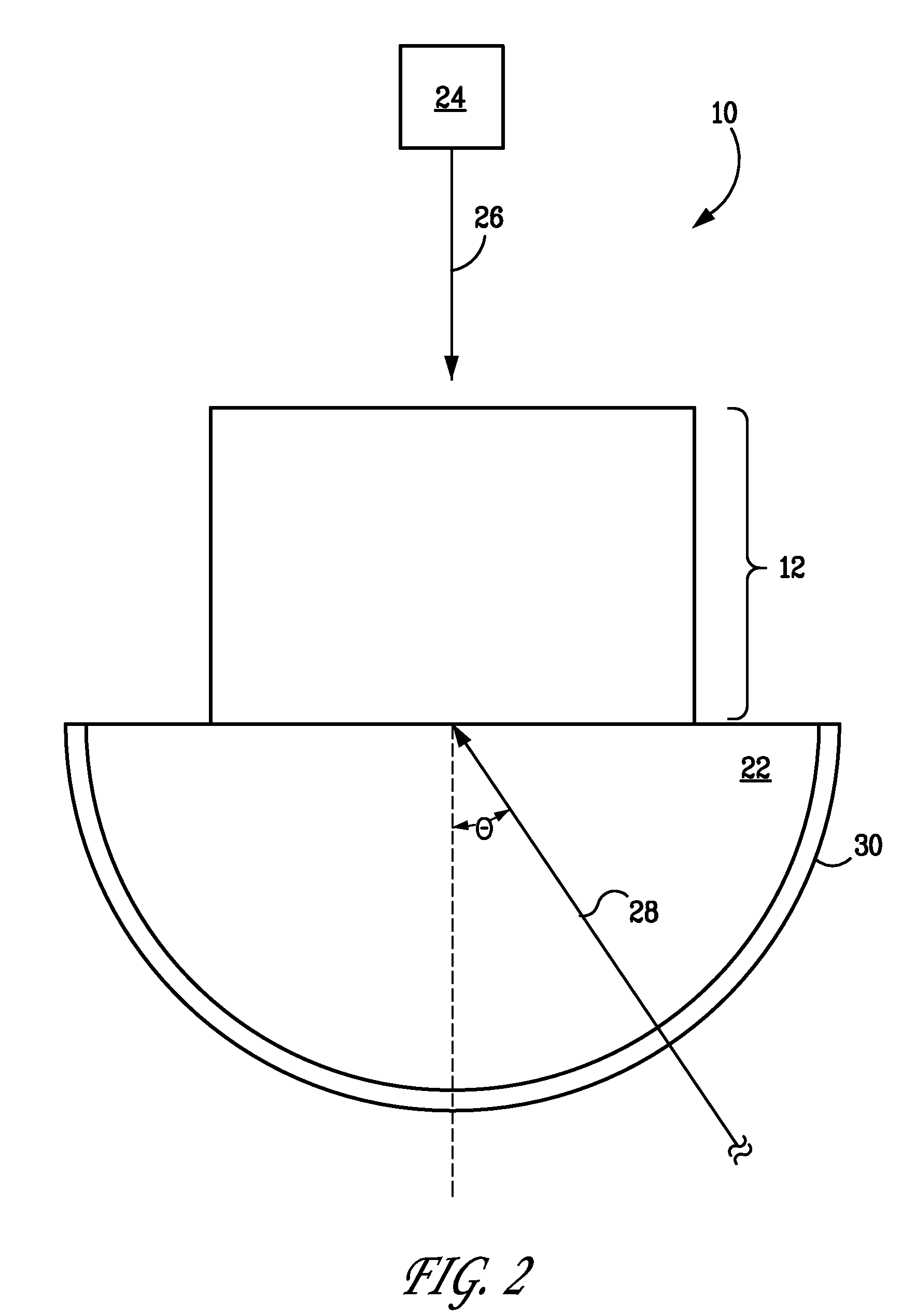

Laser amplifier and method of making the same

ActiveUS20080175292A1Improve power performanceImproved waste heat managementExcitation process/apparatusSemiconductor/solid-state device manufacturingTotal internal reflectionAudio power amplifier

The present invention includes a laser amplifier and a method of making the same. The laser amplifier of the present invention includes a gain medium layer having a first index of refraction, and a coupling layer optically coupled to the gain medium. In the various embodiments described herein, the coupling layer can have a second index of refraction less than the first index of refraction. The laser amplifier described herein can also include an evanescent layer disposed between the gain medium and the coupling layer. The evanescent layer can have a third index of refraction less than the second index of refraction. The laser amplifier provides high power, efficient laser resonance through frustrated total internal reflection and total internal reflection while simultaneously providing for the minimization of waste heat in the gain medium layer.

Owner:STC UNM

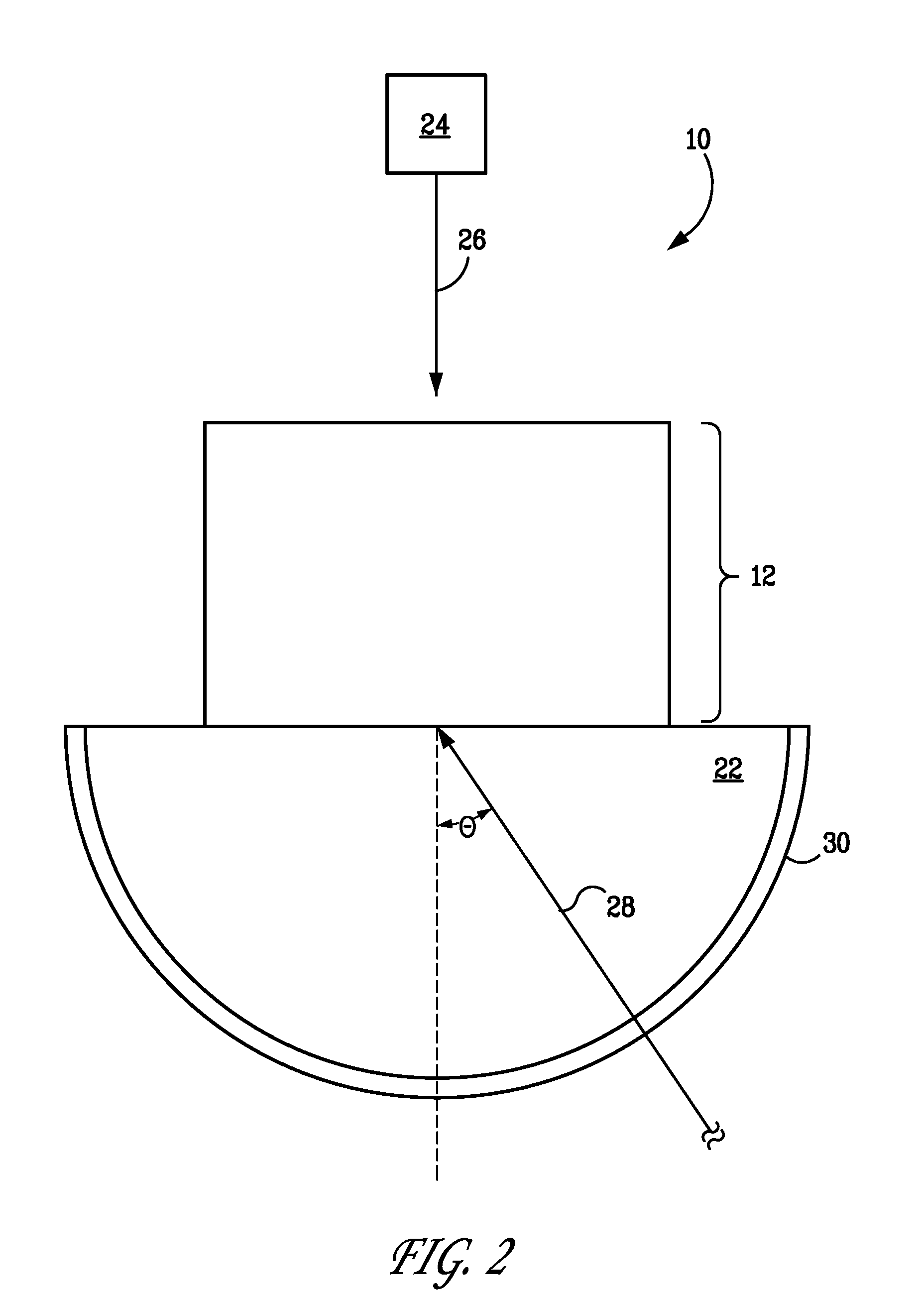

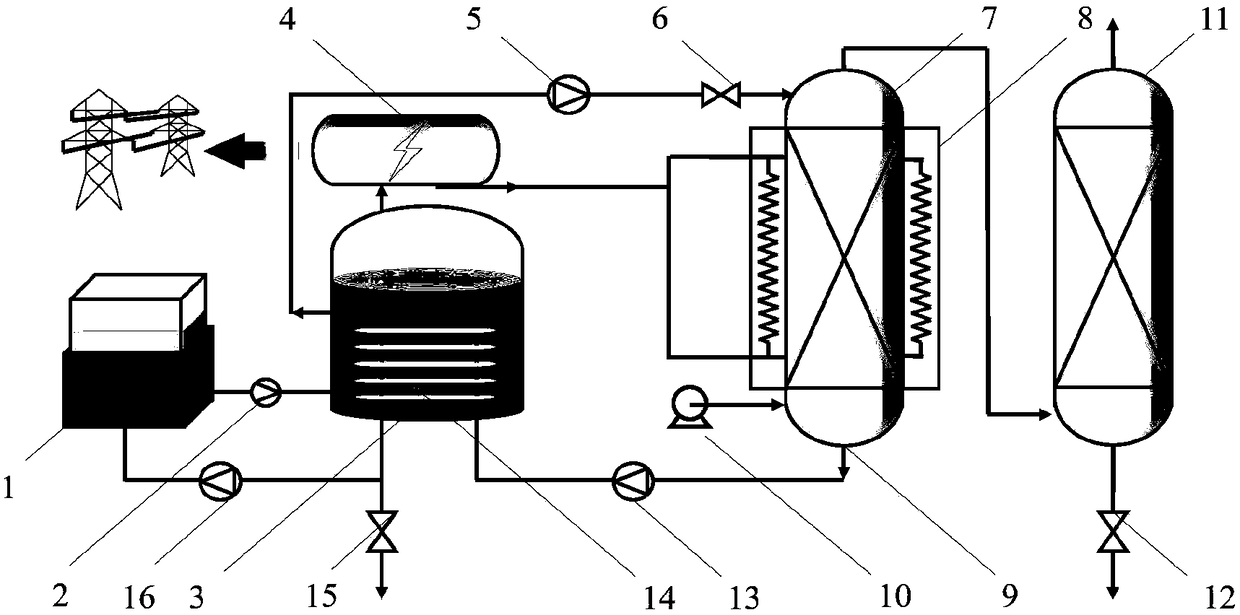

Silicon smelting electric furnace waste heat power generation process flow and configuration

ActiveCN101392992AEfficient extractionIncrease waste heatEnergy industryIncreasing energy efficiencyCooling towerAtmospheric air

The invention provides silicon smelting electric furnace waste heat power generating equipment, which consists of a valve 1, a waste heat boiler 2, a turbo generator 3, a vapor condenser 4, a cooling tower 5, a circulating water pump 6, a condensing water pump 7, a vapor seal heater 8, a low-pressure heater 9, a deaerator 10, a feed water pump 11, a chimney 12, a bag dust collector 13, an induced draft fan 14, a air cooler 15, a steel ball collection conveying distribution lifting device 17, a mixing cold air valve 18 and a by-pass valve 19, wherein waste flue gas discharged by a silicon smelting electric furnace 16 is introduced into the waste heat boiler to release partial heat; and when the temperature of the waste flue gas is reduced to nearly 180 DEG C, the waste flue gas enters the bag dust collector through the induced draft fan, and finally is discharged to atmosphere through the chimney. The desalted water enters the waste heat boiler through the feed water pump, vapor generated by the waste heat boiler enters the turbo generator; and after the vapor does work, the vapor enters the vapor condenser to be condensed into water, and the water enters the deaerator through a condensate removal pump, and the deoxidized water enters the waste heat boiler through the feed water pump. The silicon smelting electric furnace waste heat power generating equipment has the advantages of good energy saving effect, little investment and low cost.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

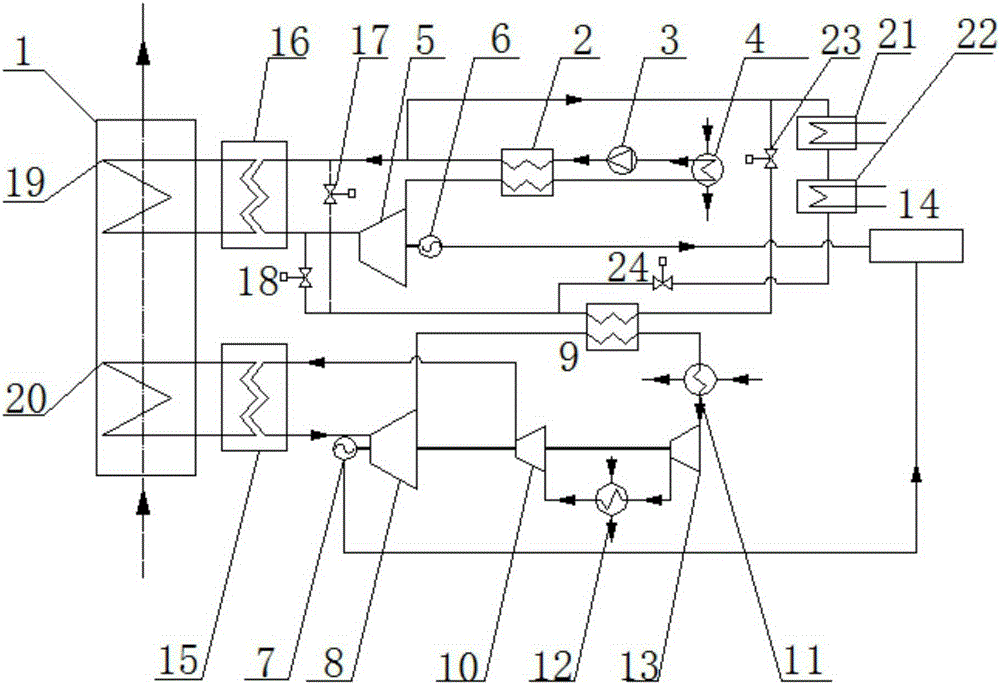

Marine diesel engine tail gas waste heat power generation system utilizing S-CO2 and ORC combined cycle

ActiveCN105257426AImprove temperature matchingIncrease heat transfer areaInternal combustion piston enginesEngine componentsHeat conductingDiesel engine

The invention aims at providing a marine diesel engine tail gas waste heat power generation system utilizing an S-CO2 and ORC combined cycle. The system comprises a diesel engine exhaust heat exchanger, a super-critical CO2 cycle power generation system and an ORC cycle power generation system. The super-critical CO2 system and the ORC system jointly recycle tail gas waste heat of a diesel engine. The device is composed of the super-critical CO2 circulating system and the ORC circulating system matched with the super-critical CO2 circulating system. Heat conducting oil is adopted as a heat transfer medium, and the tail gas waste heat is transmitted to the super-critical CO2 circulating system and the ORC circulating system and serves as a heat source for the two circulating systems. The super-critical CO2 circulating system and the ORC circulating system are matched for power generation. A finned tube heat exchanger is connected to a diesel engine exhaust channel, the heat conducting oil passes through a channel inside heat exchanger tubes, and diesel engine tail gas passes through channels outside the tubes. The exhaust waste heat energy of the marine diesel engine is effectively recycled and converted into electric energy, waste heat of a marine main engine is comprehensively recycled, the heat efficiency of the diesel engine is remarkably improved, and the ship EEDI energy-consumption index is reduced.

Owner:HARBIN ENG UNIV

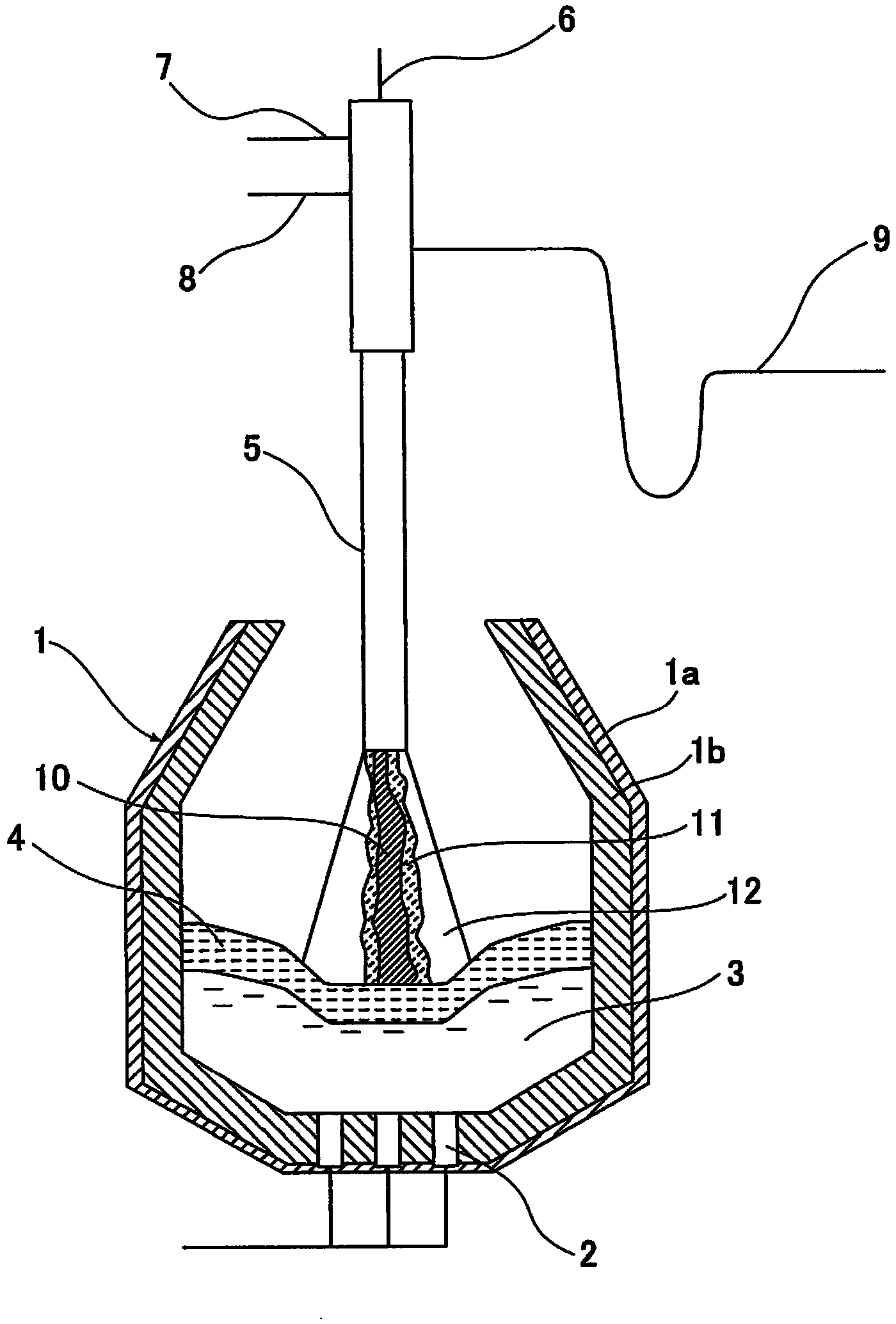

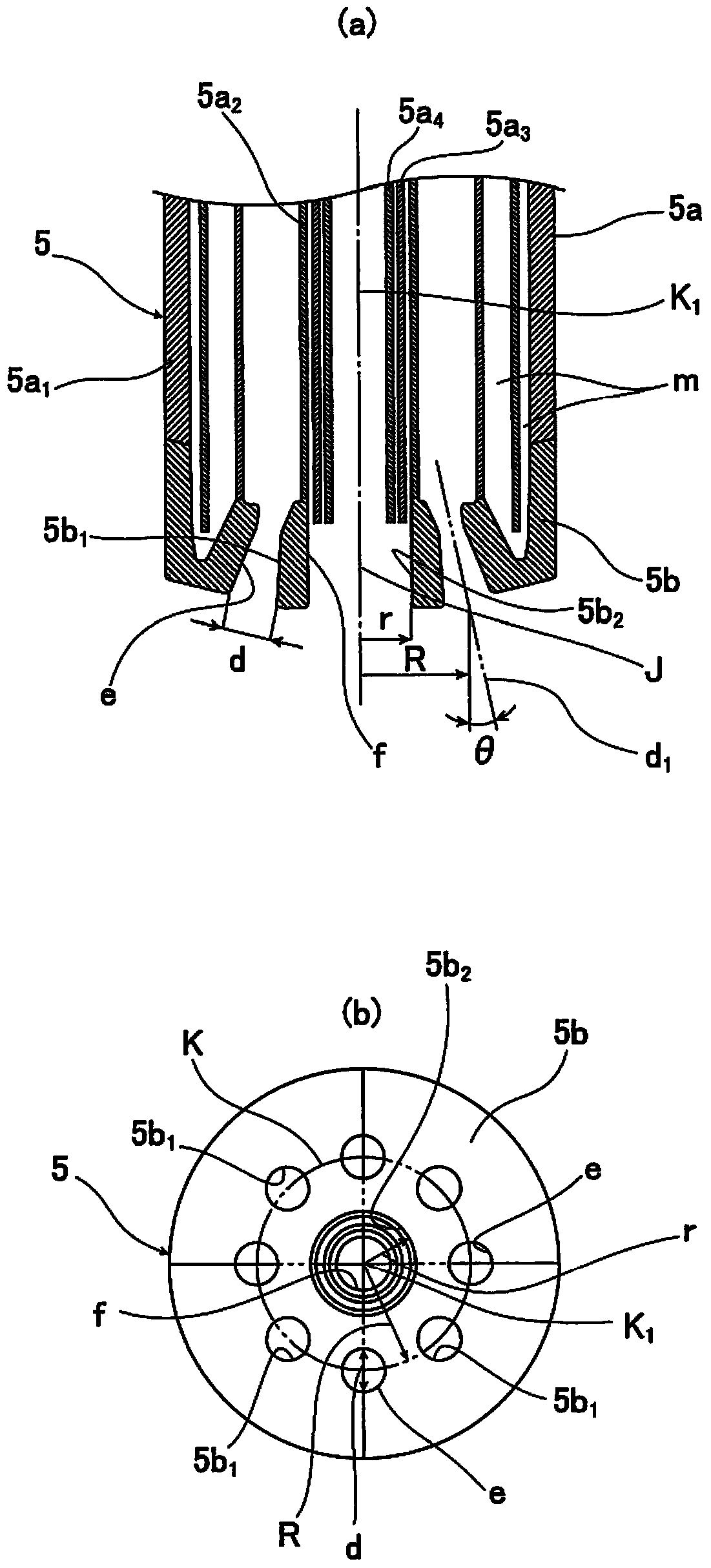

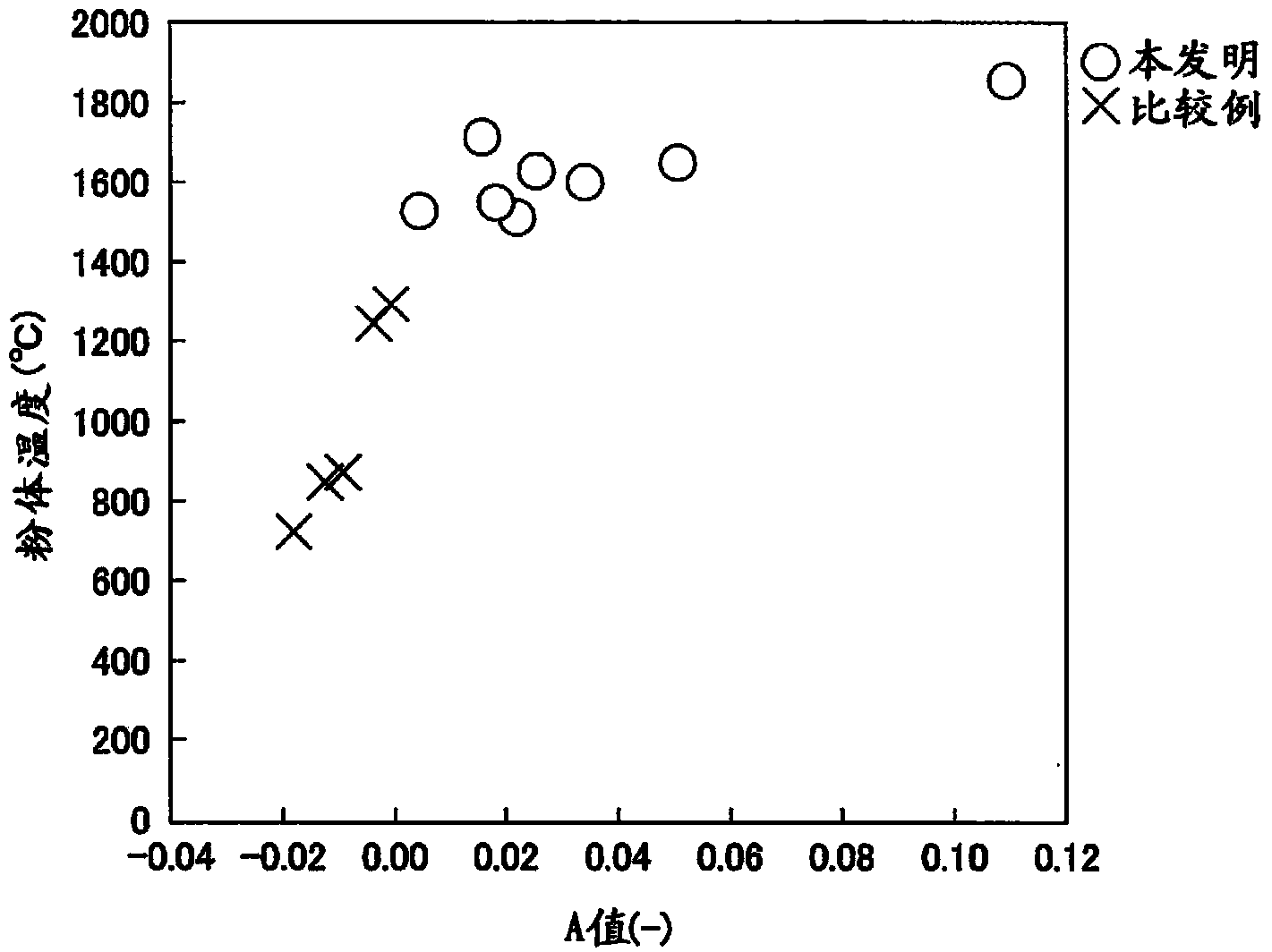

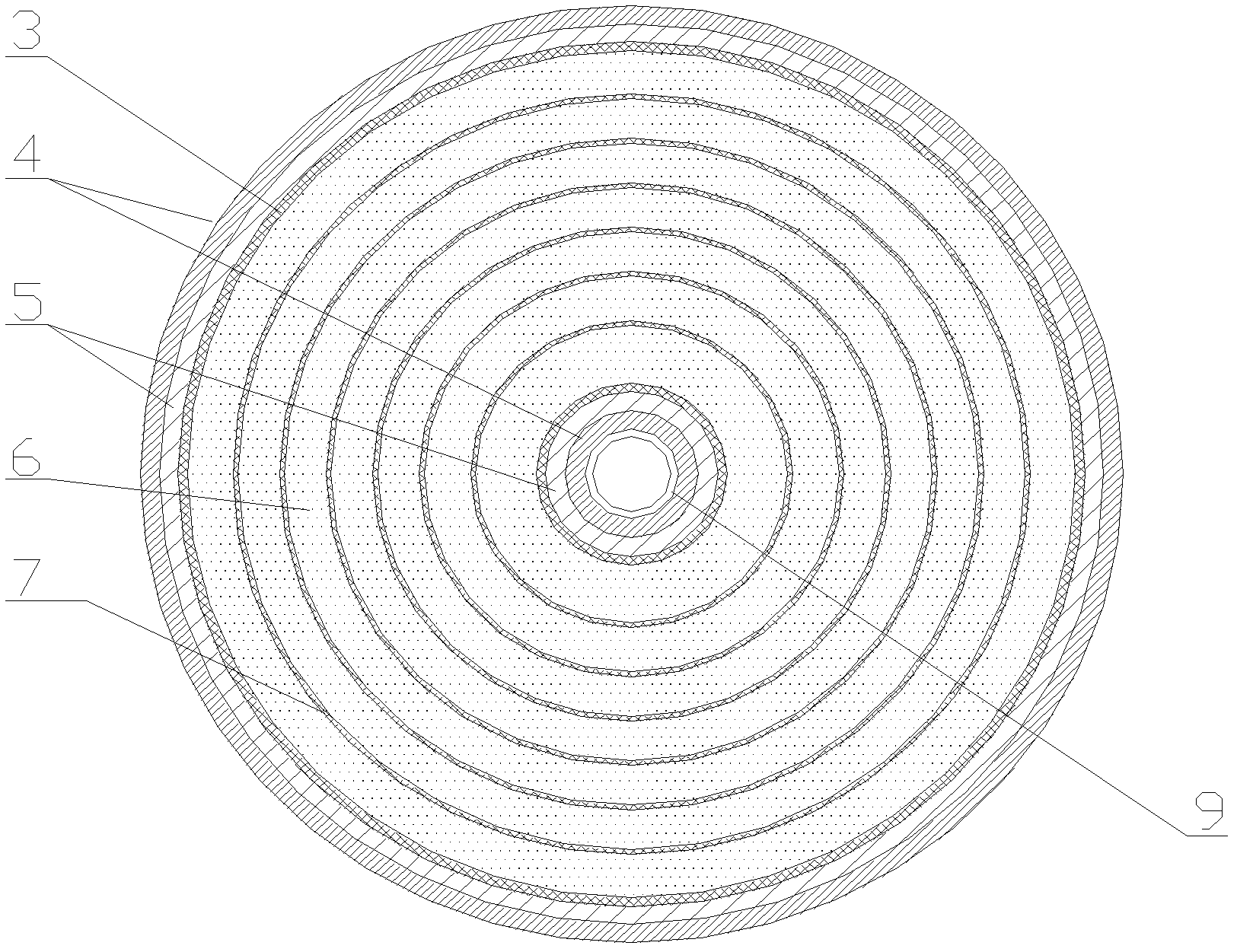

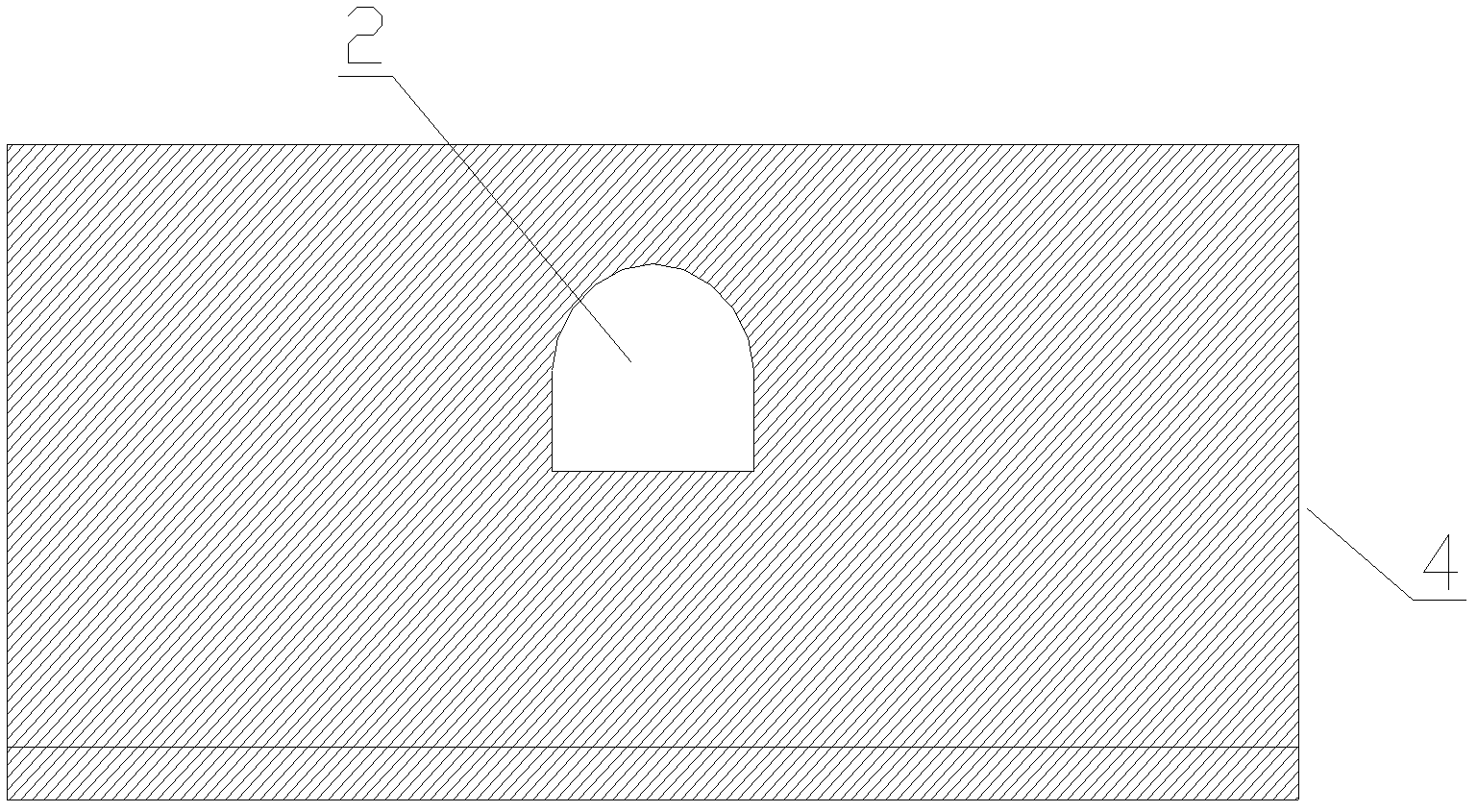

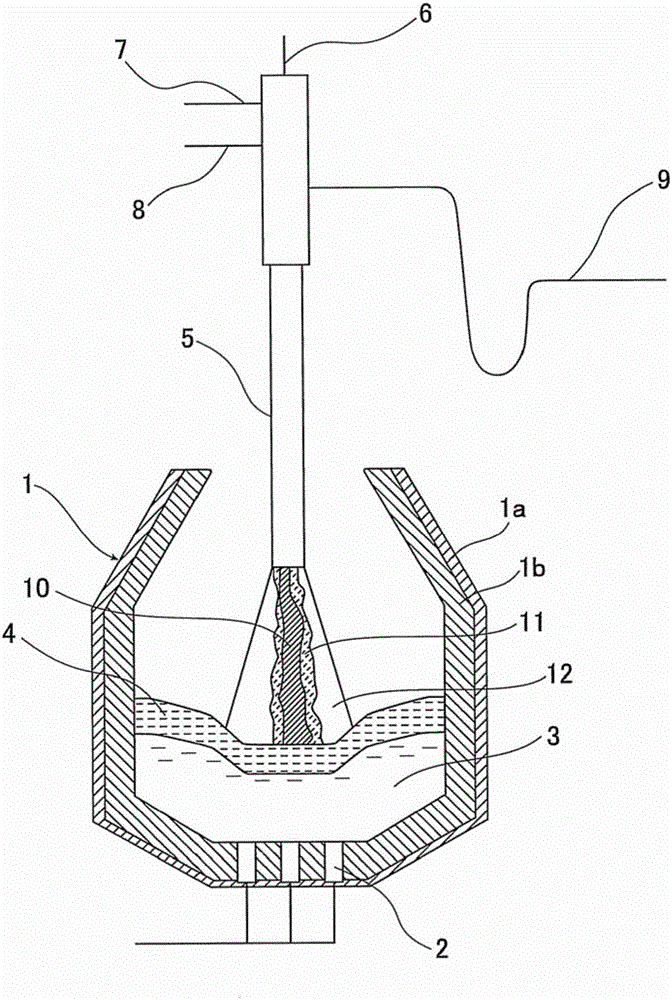

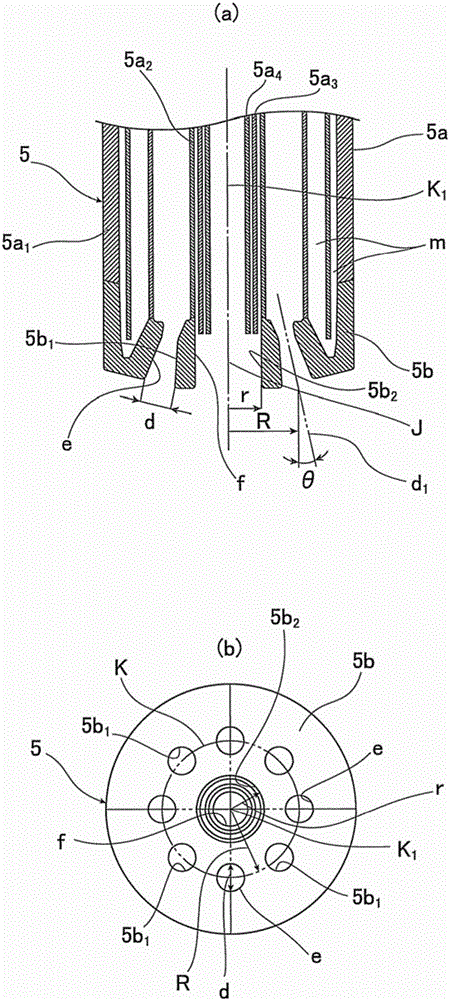

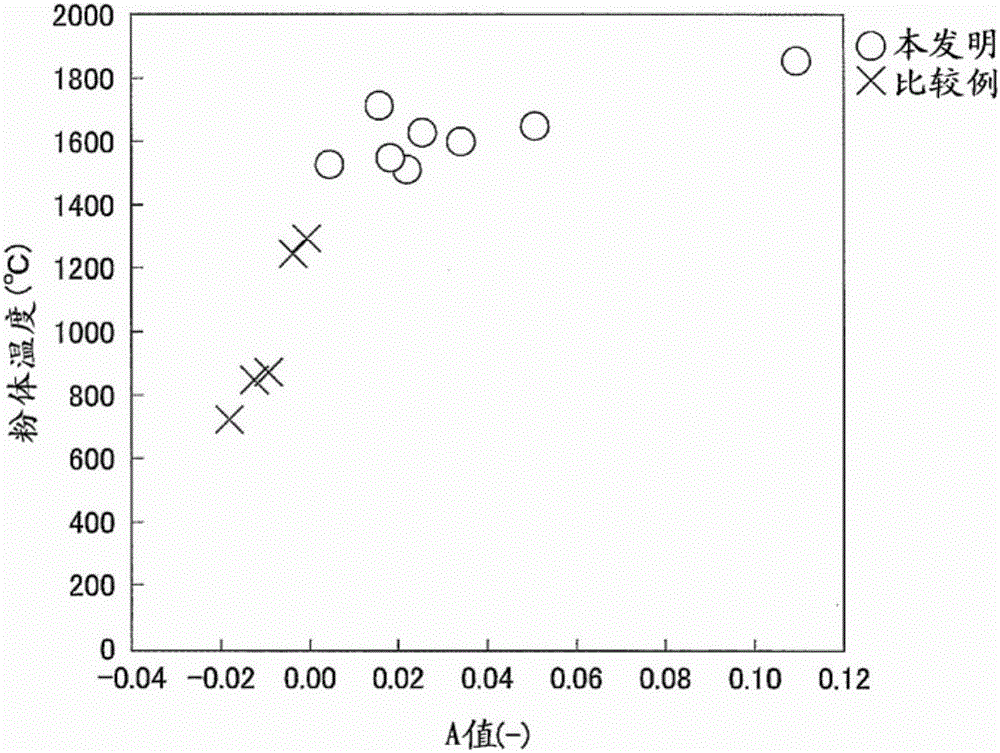

Powder injection lance and method of refining molten iron using the powder injection lance

ActiveCN103890199AReduce distractionsImprove heat transfer efficiencyManufacturing convertersProcess efficiency improvementMaterials scienceHeat transfer

A powder injection lance is provided with: a refining oxygen gas injection nozzle which has multiple ejection openings that are arranged at intervals along a circular trajectory and inject an oxygen gas into an iron bath housed in a reaction vessel; and a burner nozzle which has an axial center coaxial with the central axis of the circular trajectory, and which has an ejection opening which forms a flame on the inside of the refining oxygen gas injection nozzle and which injects into the iron bath a powder to which heat has been transferred by the flame. An indicator showing the positional relation between the ejection opening of the refining oxygen gas injection nozzle and the ejection opening of the burner nozzle fulfills A=1.7(R-r-d / 2) / L+tan(theta-12 DEG )-0.0524>0. Here, R is the radius (mm) of the circular trajectory, r is the radius (mm) of the ejection opening of the burner nozzle, d is the diameter (mm) of the ejection openings of the refining oxygen nozzle, theta is the inclination angle (DEG) of the axial center of the refining oxygen gas injection nozzle, and L is the lance height (mm). By this means, the efficiency of heat transfer to the iron bath is improved.

Owner:JFE STEEL CORP

High-temperature neutral blowoff high-efficiency anaerobic fermentation apparatus and fermentation method

InactiveCN108249726AGuaranteed uptimeEasy to recycleInternal combustion piston enginesClimate change adaptationSlurryFermentation

The invention relates to a high-temperature neutral blowoff high-efficiency anaerobic fermentation apparatus and a fermentation method. The high-temperature neutral blowoff high-efficiency anaerobic fermentation apparatus comprises a raw material premixing tank, an anaerobic fermentation tank and a biogas slurry blowoff system which are successively connected with one another; the biogas slurry blowoff system comprises a blowoff tower, an ammonia gas absorption tower connected with a gas outlet of the blowoff tower, and a heating system for heating the blowoff tower; and a biogas outlet of theanaerobic fermentation tank is connected with a generator, and a waste heat collection apparatus disposed outside the generator is connected with the heating system. No alkaline agent is added in theblowoff process, the problems of mass foam and corrosion in the blowoff process can be effectively reduced, the expense for buying a chemical alkaline agent is reduced, the problem that alkaline tailwater after the blowoff is difficult to discharge can be avoided, the accumulation and inhibition problem of ammonium and nitrogen in the fermentation tank can be alleviated, and the high-temperatureneutral blowoff high-performance anaerobic fermentation apparatus and the fermentation method have important significance for ensuring the high-efficient and stable operation of a large-middle-sizedbiogas project.

Owner:CHINA AGRI UNIV

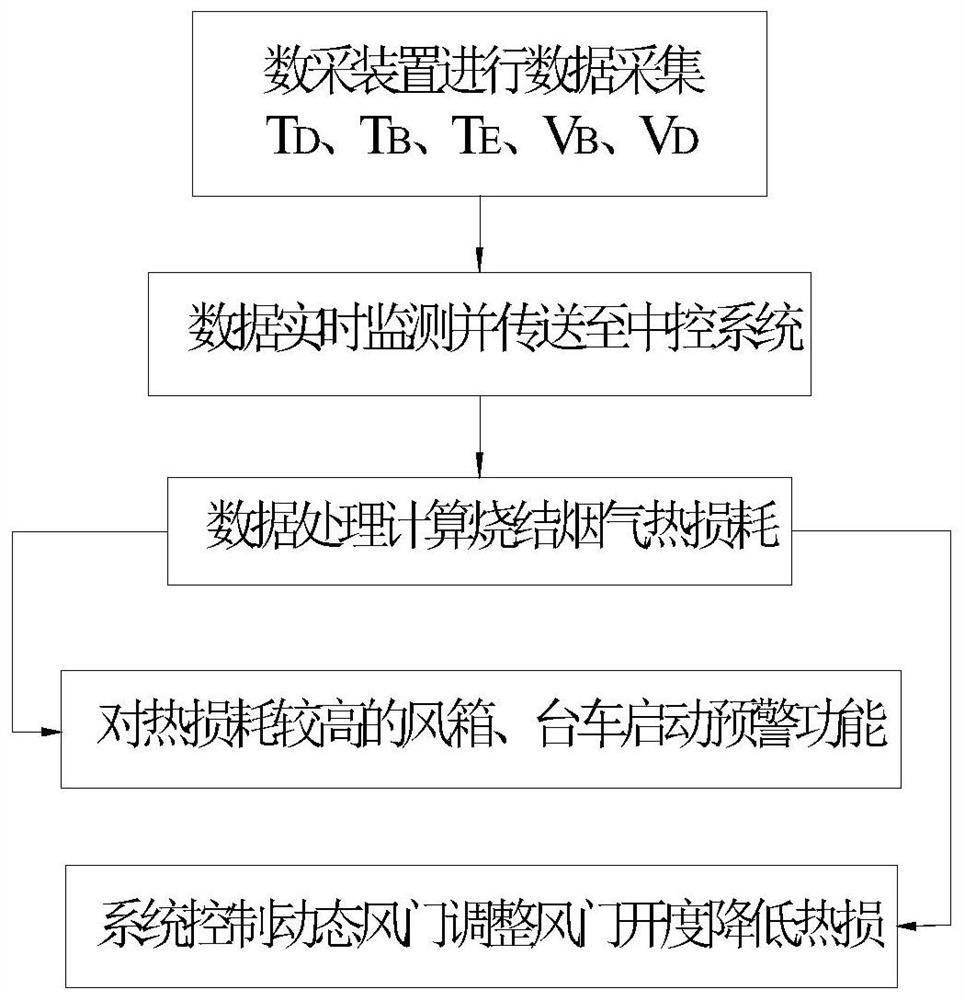

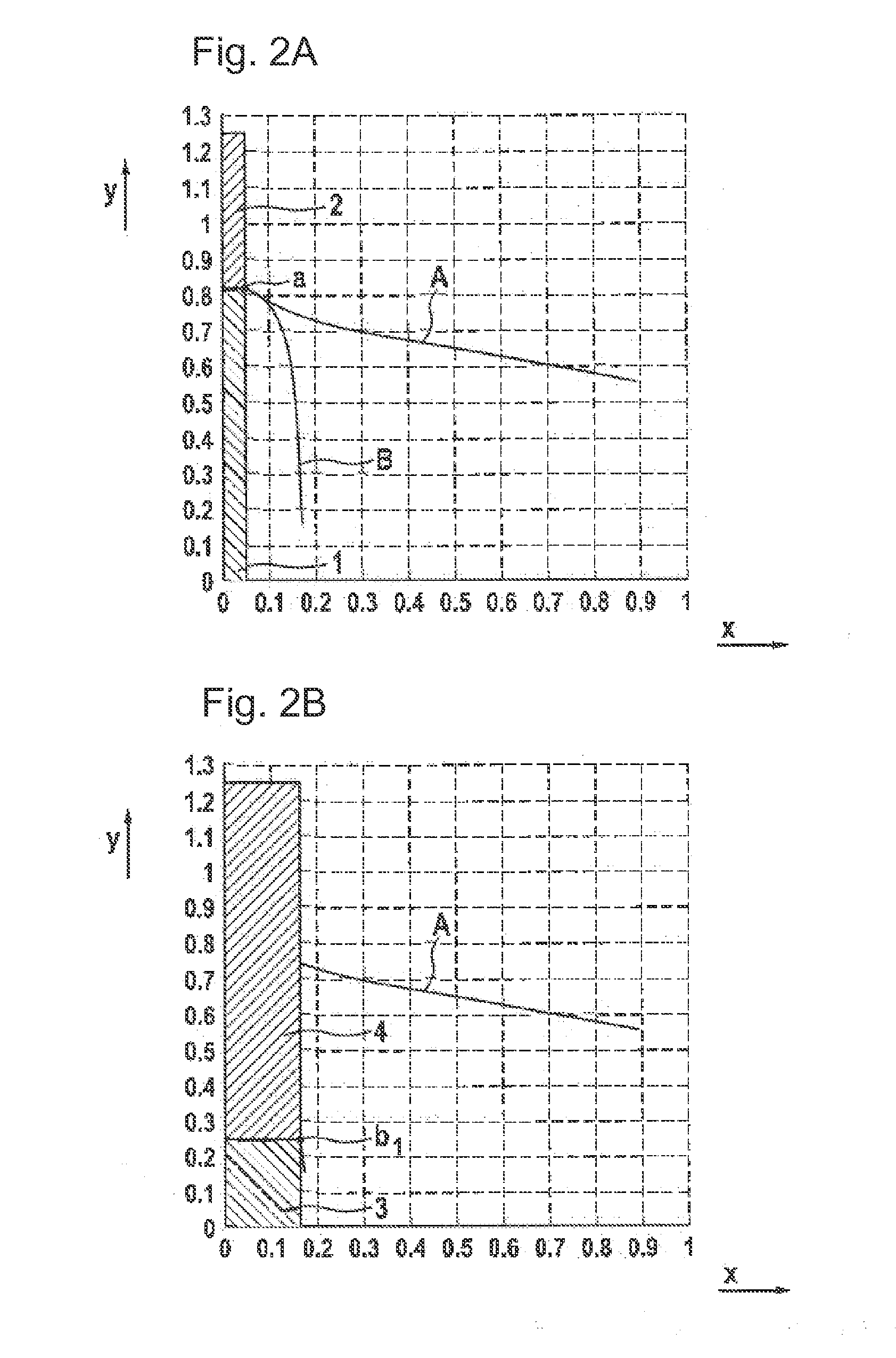

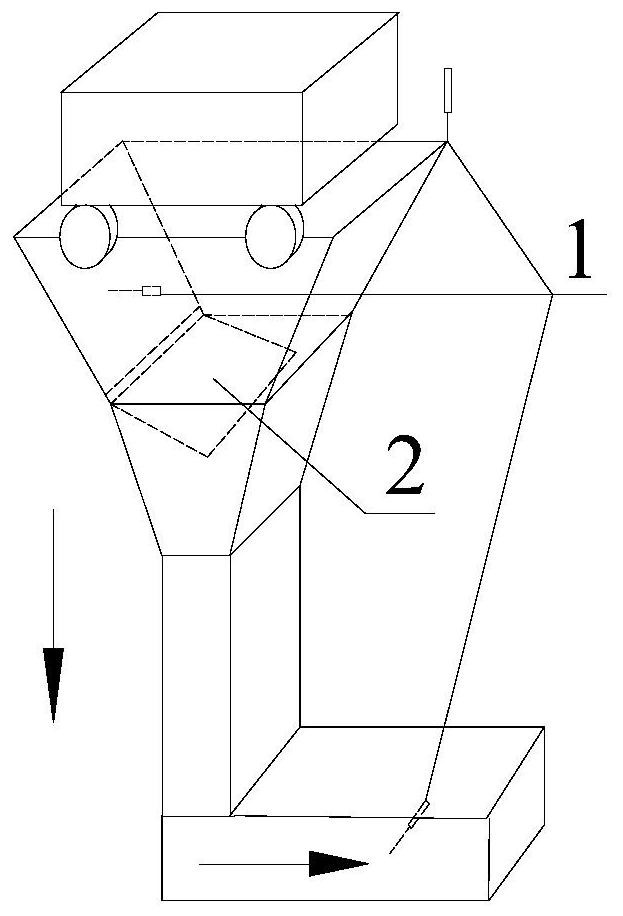

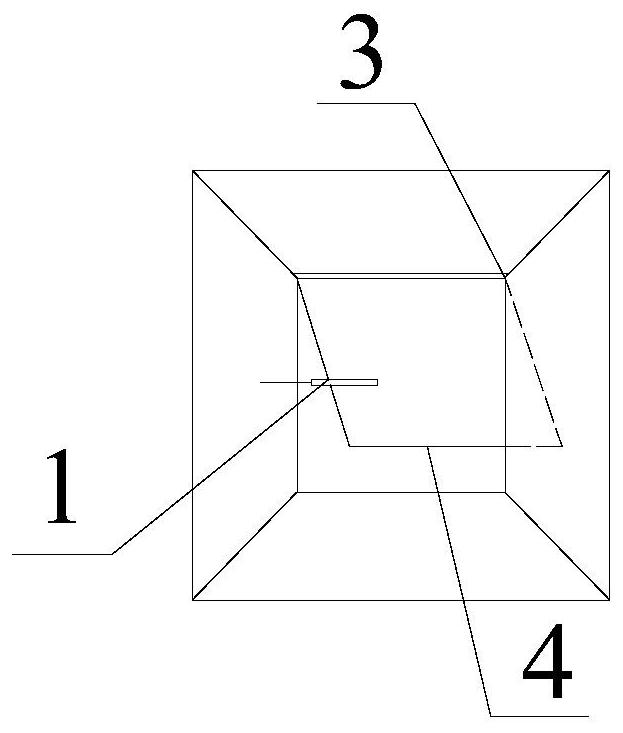

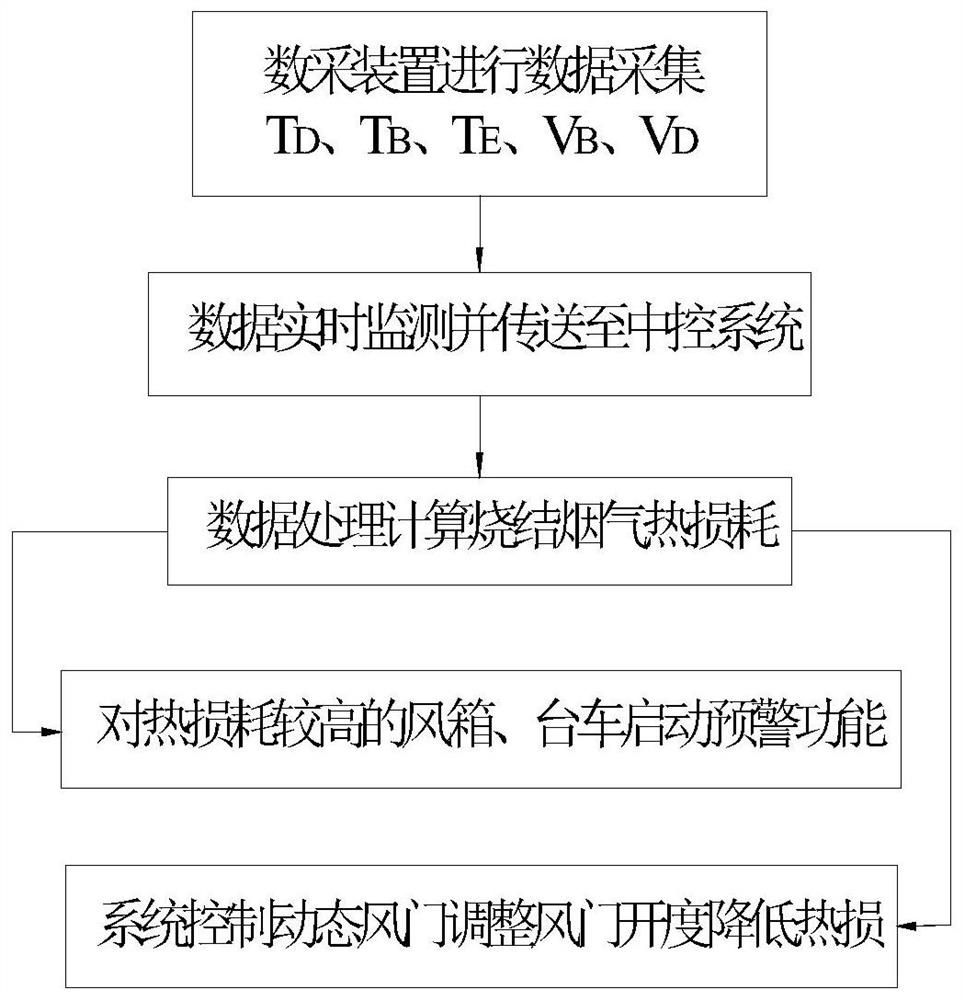

Waste heat monitoring and adjusting method for sintering machine

PendingCN113587650AIncrease waste heatReduce production energy consumptionCharge treatment typeFurnace typesServicing equipmentFlue gas

The application discloses a waste heat monitoring and adjusting method for a sintering machine. The method comprises the steps: step 1, collecting devices are arranged; step 2, during sintering, the temperature of each collecting device in the sintering process is recorded, the ambient temperature of the sintering machine is recorded as TE, the temperature below a sintering trolley grate bar is recorded as TB, the temperature of a sintering flue is recorded as TD, the flue gas flow of each collecting device in the sintering process is recorded, the flue gas flow below the sintering trolley grate bar is recorded as VB, the flue gas flow of the sintering flue is recorded as VD, and the sintering flue gas atmosphere composition is recorded; step 3, the waste heat keeping rate of the sintering machine is calculated according to data collected in step 2; and step 4, field workers are guided to adjust production parameters according to the waste heat keeping rate of the sintering machine. According to the waste heat monitoring and adjusting method for the sintering machine, monitoring and early warning can be conducted on the waste heat of the sintering machine, field workers are guided in time to adjust the production parameters and replace maintenance equipment, the waste heat of the sintering machine is improved, the production energy consumption of enterprises is reduced, and considerable additional benefits are created.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +2

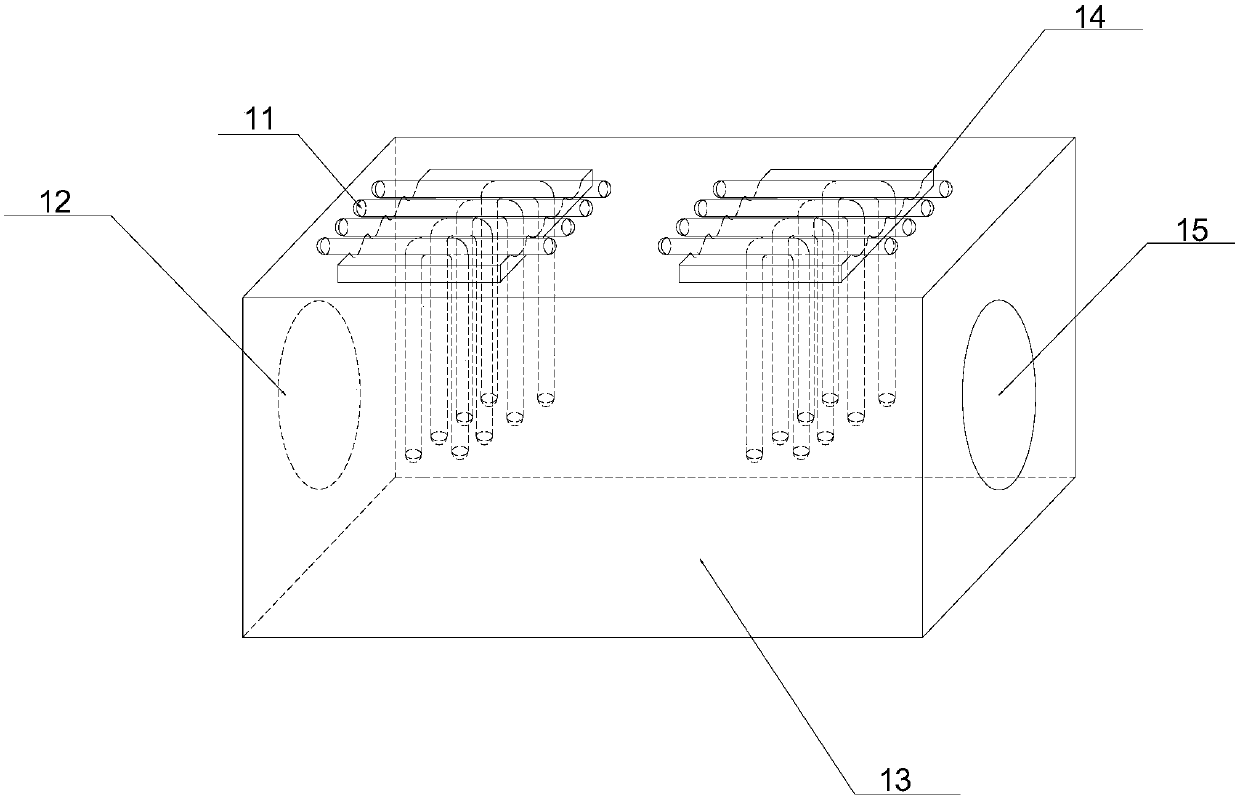

Multi-stage heat tube enhanced heat exchange ship exhaust gas waste heat temperature-difference power generation device and method

InactiveCN107612425AHigh thermal efficiencyIncrease waste heatGenerators/motorsFlue gasEnhanced heat transfer

The invention discloses a multi-stage heat tube enhanced heat transfer ship exhaust gas waste heat temperature-difference power generation device and method. The multi-stage heat tube enhanced heat exchange ship exhaust gas waste heat temperature-difference power generation device comprises a device body structure, a rear side copper plate, a front side copper plate, a top end copper plate, a temperature-difference power generation sheet, a heat-end heat tube, a cold-end heat tube, a cold-end copper plate and a cooling copper plate. A flue gas inlet is formed in the front end of the device body structure, and a flue gas outlet is formed in the tail end. The top end copper plate is installed at the top of the device body structure, and the front side copper plate and the rear side copper plate are installed on the front side and the rear side. According to the multi-stage heat tube enhanced heat exchange ship exhaust gas waste heat temperature-difference power generation device and method, the heat end of the temperature-difference power generation sheet performs heat exchange based on heat tube enhancement, the heat efficiency off the device is improved, and the waste heat recovered under unit length is remarkably increased. The cold end of the power generation sheet performs heat exchange based on heat tube enhancement, heat carried away by cooling water under the unit lengthis increased, the low temperature at the cold end is kept, the temperature difference of the cold end and the heat end of the power generation sheet, is ensured, and the overall performance with the device output power of unit length as a reference is greatly improved.

Owner:DALIAN MARITIME UNIVERSITY

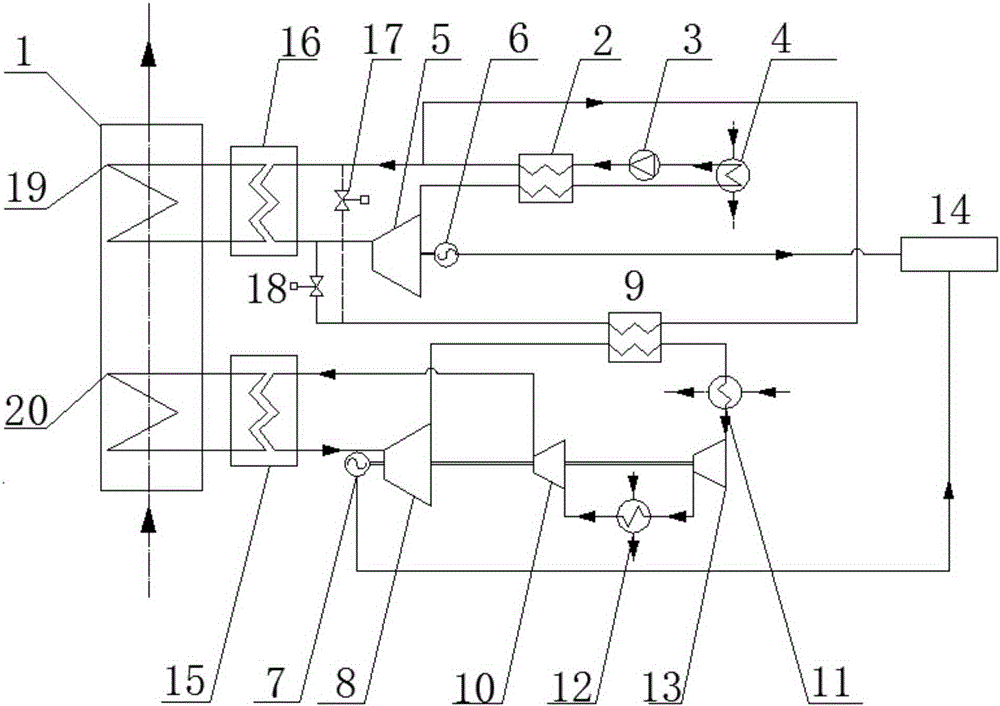

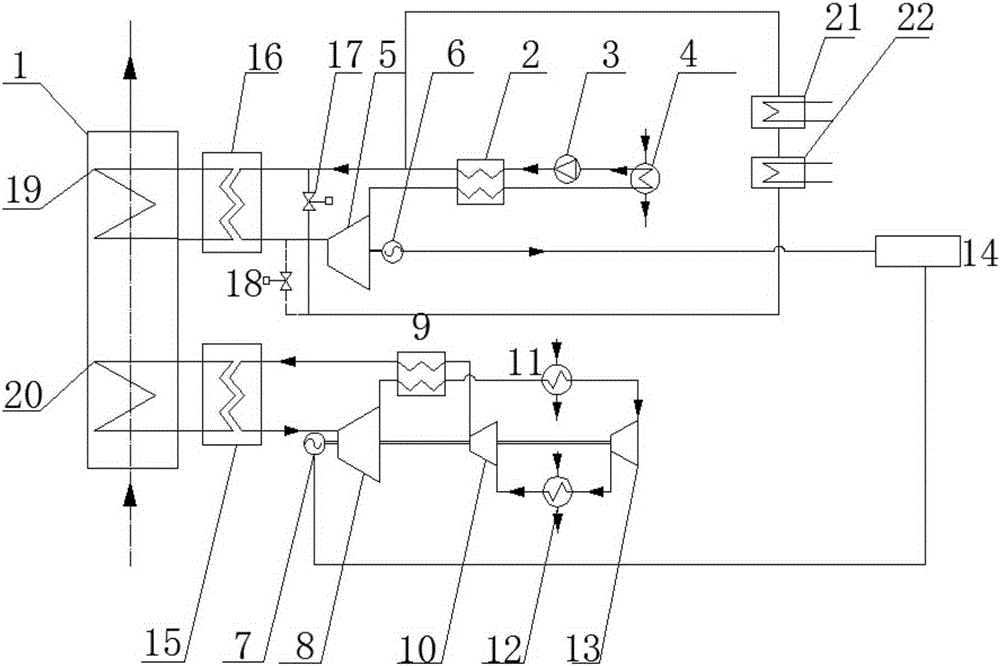

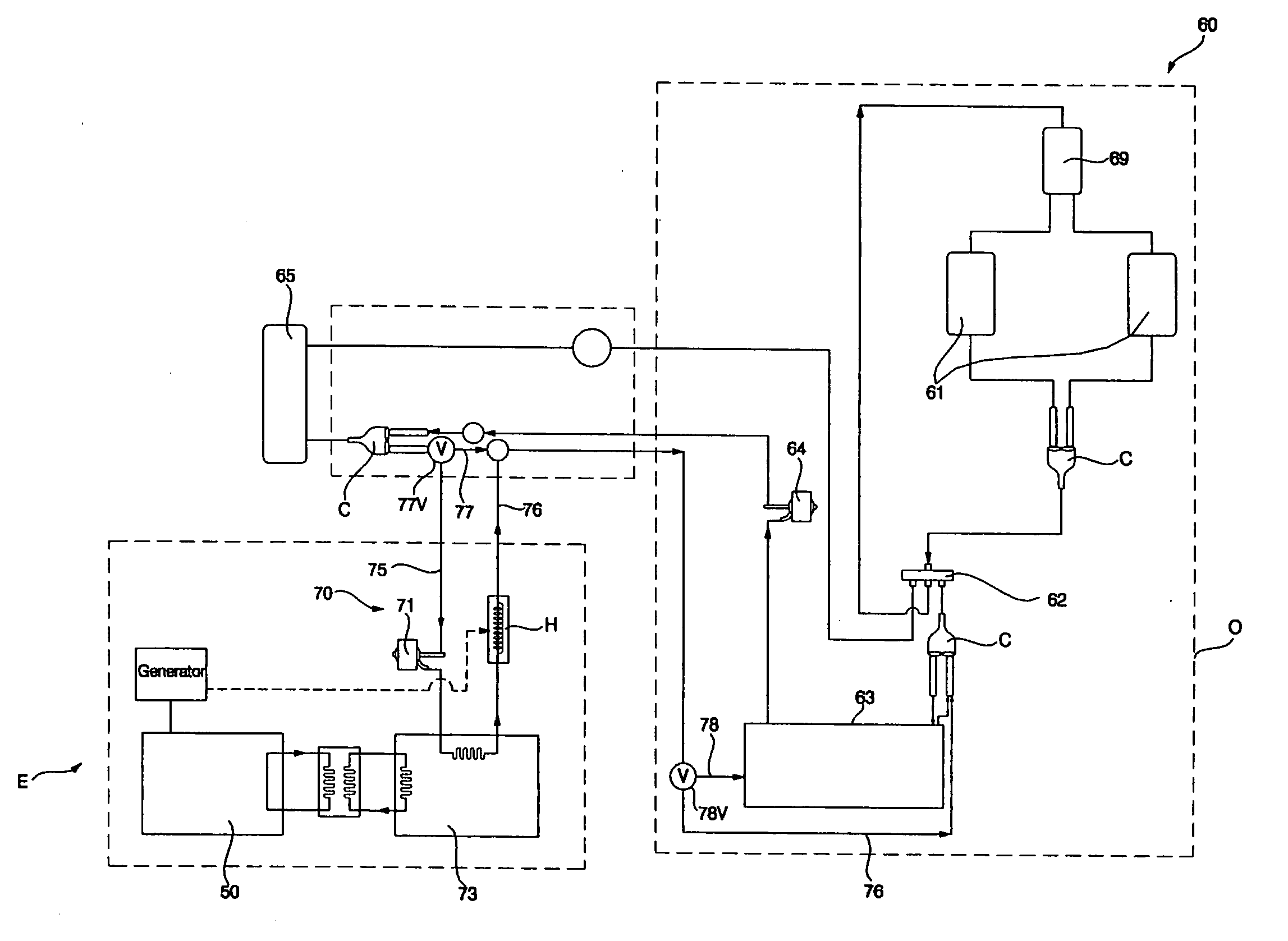

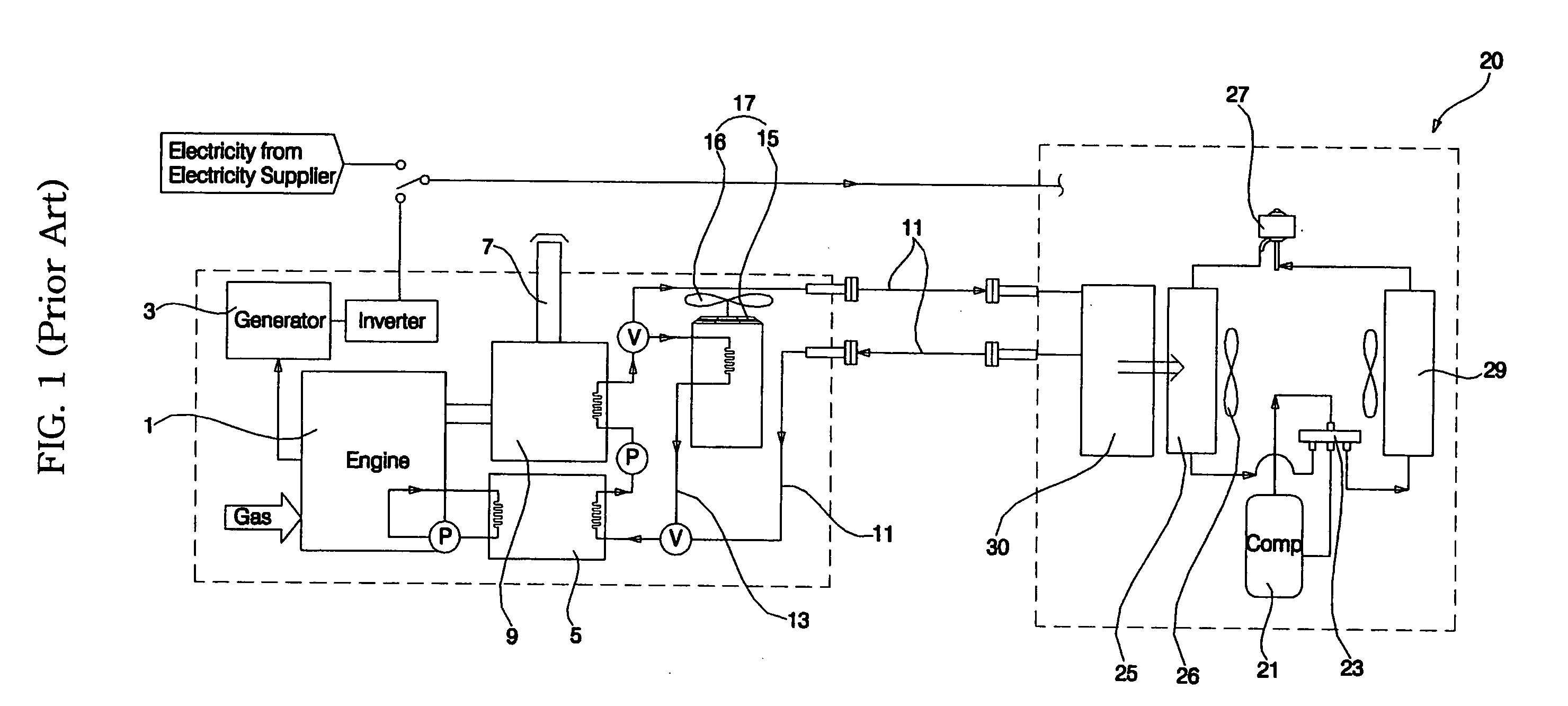

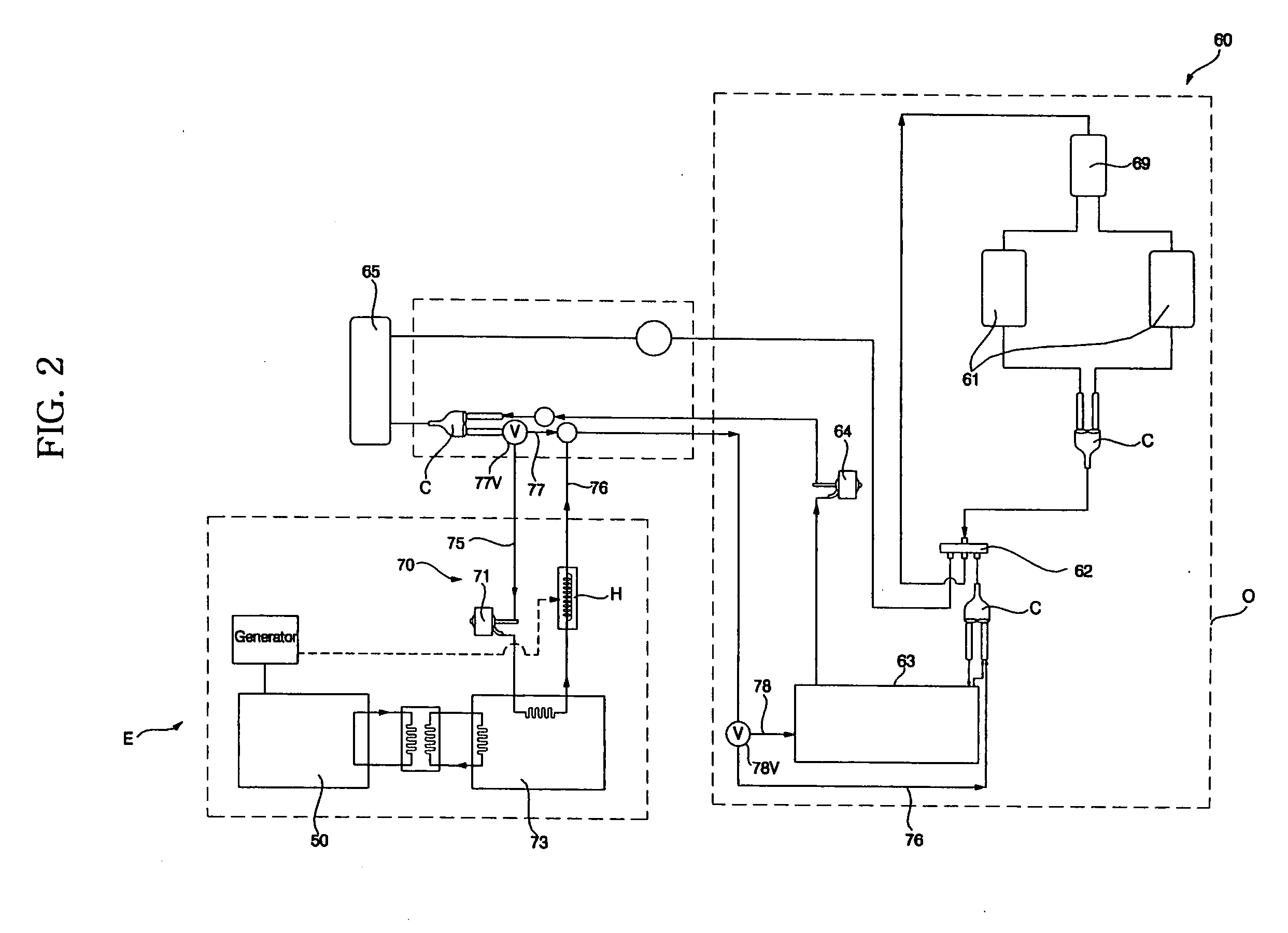

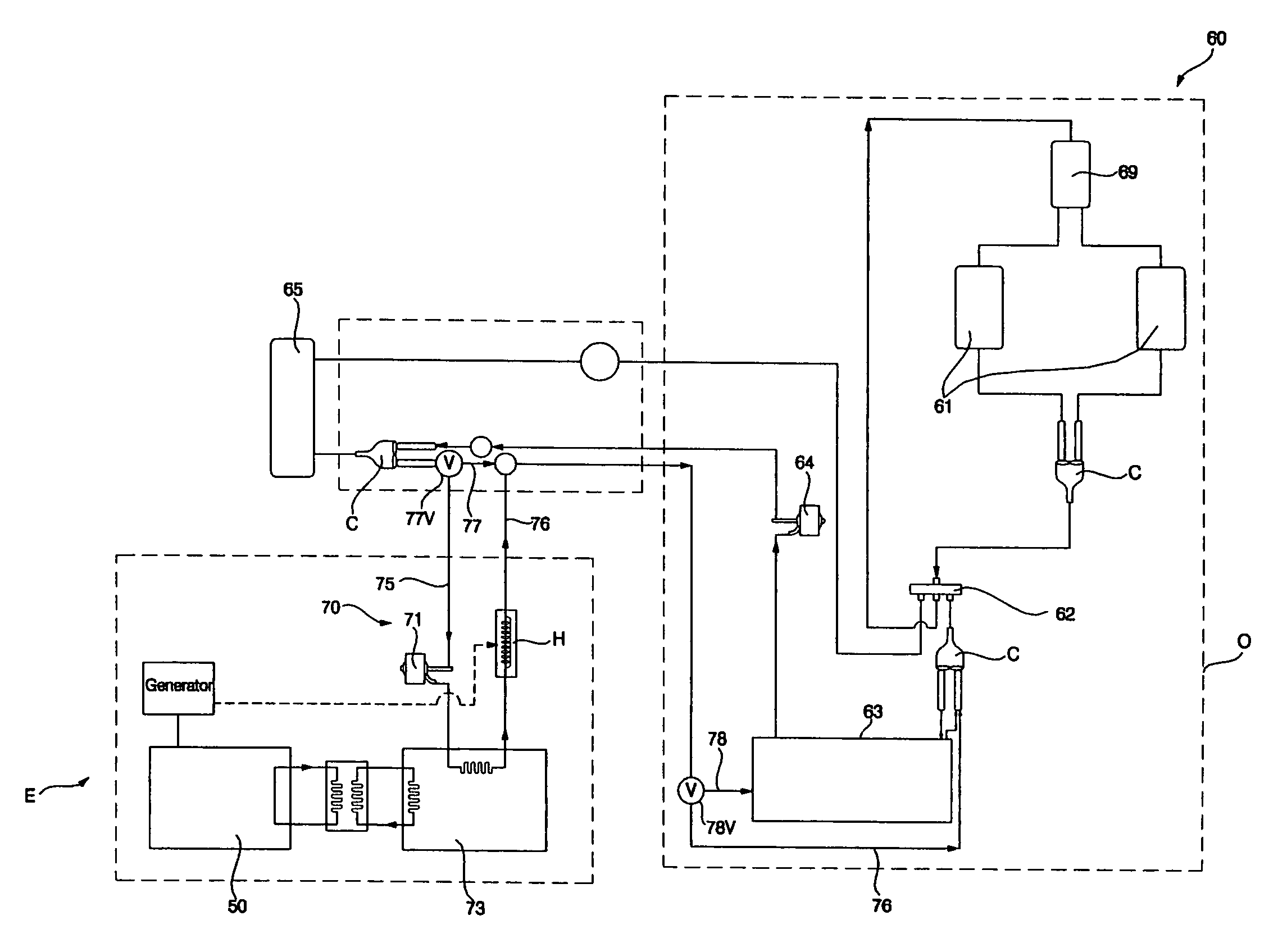

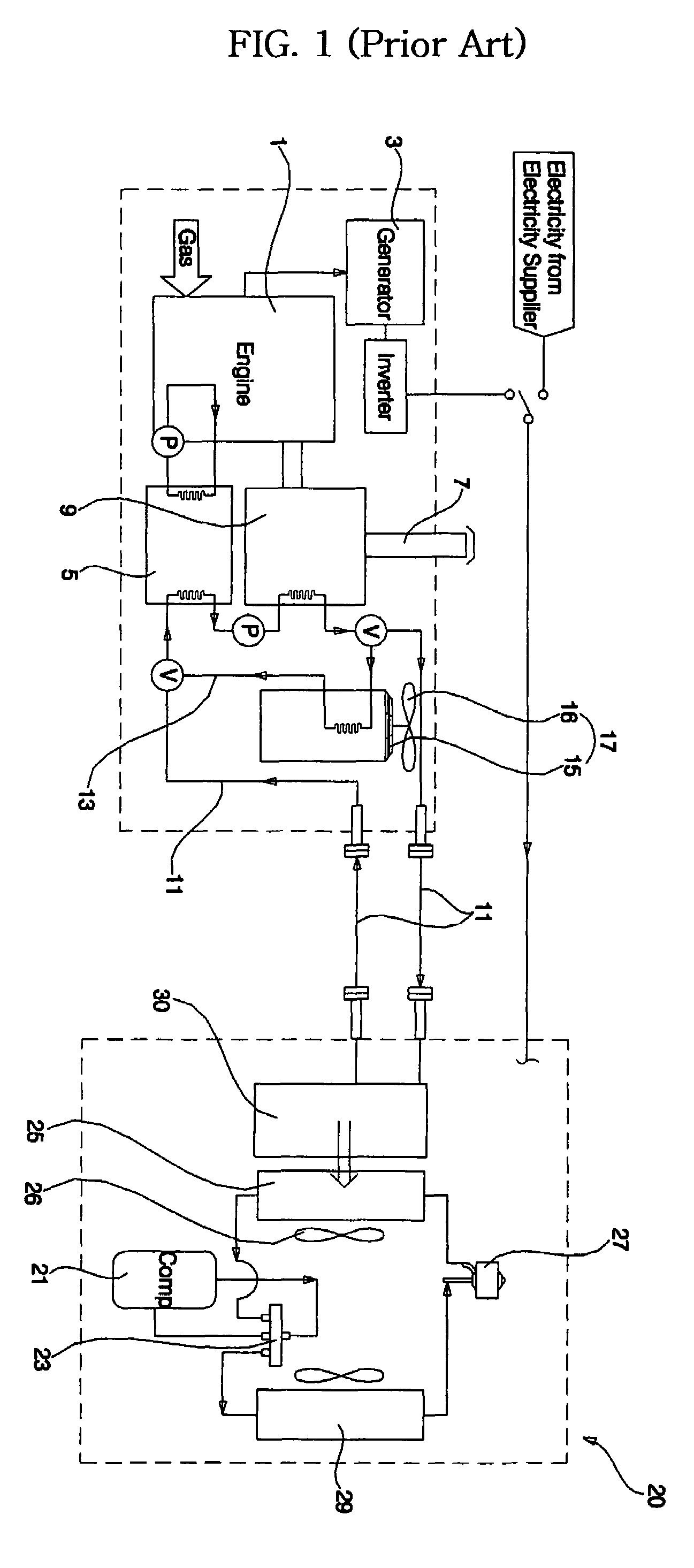

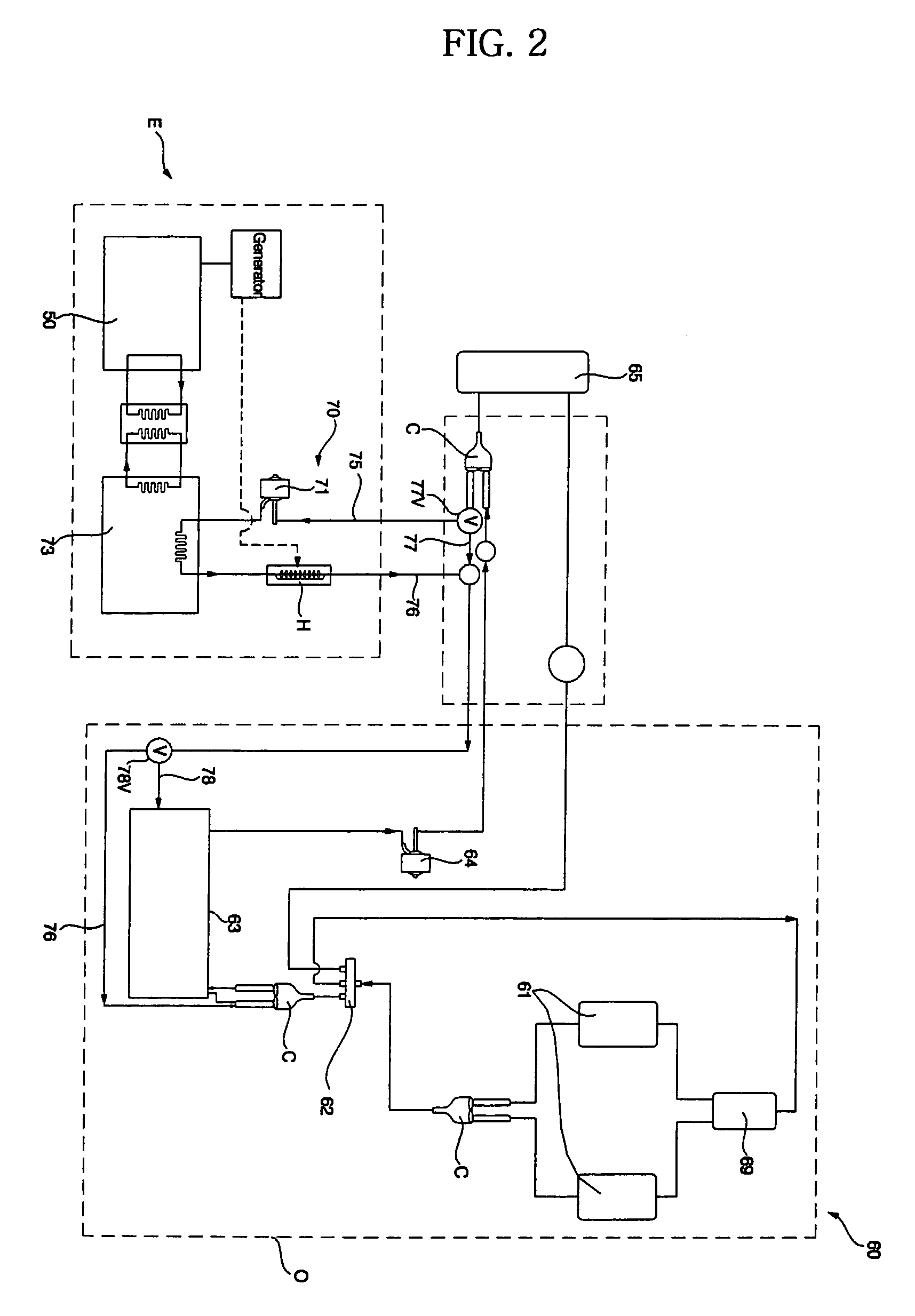

Cogeneration system

InactiveUS20060037345A1Maximize utilizationImprove the heating effectHeat pumpsClimate change adaptationElectricityFour-way valve

A cogeneration system including an engine, which drives a generator to generate electricity, a cooling / heating unit using a heat pump type refrigerant cycle, in which a refrigerant is circulated through at least one compressor, a four-way valve, a first outdoor heat exchanger, a first expansion device, and an indoor heat exchanger, in this order, during a cooling operation of the cogeneration system, and a waste heat consuming heating unit using a refrigerant cycle, in which the refrigerant is circulated through the compressor, the four-way valve, the indoor heat exchanger, a second expansion device, and a second outdoor heat exchanger to be heated by waste heat of the engine, in this order, during a heating operation of the cogeneration system. In accordance with the cogeneration system, it is possible to maximize utilization of engine waste heat during the heating operation and to achieve an enhancement in heating performance.

Owner:LG ELECTRONICS INC

Cogeneration system

InactiveUS7243504B2Increase waste heatImprove the heating effectHeat pumpsClimate change adaptationElectricityFour-way valve

A cogeneration system including an engine, which drives a generator to generate electricity, a cooling / heating unit using a heat pump type refrigerant cycle, in which a refrigerant is circulated through at least one compressor, a four-way valve, a first outdoor heat exchanger, a first expansion device, and an indoor heat exchanger, in this order, during a cooling operation of the cogeneration system, and a waste heat consuming heating unit using a refrigerant cycle, in which the refrigerant is circulated through the compressor, the four-way valve, the indoor heat exchanger, a second expansion device, and a second outdoor heat exchanger to be heated by waste heat of the engine, in this order, during a heating operation of the cogeneration system. In accordance with the cogeneration system, it is possible to maximize utilization of engine waste heat during the heating operation and to achieve an enhancement in heating performance.

Owner:LG ELECTRONICS INC

Method for operating a fuel cell and fuel cell system with improved thermal control

InactiveUS20130101913A1Low efficiencyIncrease waste heatFuel cell heat exchangeTransportation fuel cell technologyPower flowFuel cells

The present invention relates to a method for operating a fuel cell system, comprising the following method steps:a) conducting a defined quantity of anode gas to an anode and conducting a defined quantity of cathode gas to a cathode, wherein a defined voltage is set at a defined current consumption and a defined power provision, whereinb) in order to increase the waste heat of the fuel cell for a defined, temporally limited duration, the fuel cell is operated in a cathode gas depletion state.Such a method provides improved thermal control of the fuel cell even in the case of coldstarting or after operation in the partial load mode. The present invention also relates to a fuel cell system.

Owner:ROBERT BOSCH GMBH

Sintering machine residual heat monitoring and adjusting method

PendingCN113091460AIncrease waste heatReduce production energy consumptionFurnace typesControl devices for furnacesMetallurgyFlue gas

The invention discloses a sintering machine residual heat monitoring and adjusting method. The sintering machine residual heat monitoring and adjusting method comprises the following steps: step 1, an acquisition device is arranged; step 2, during sintering, the temperature of each acquisition device in the sintering process is recorded, the environment temperature of a sintering machine is recorded as T<E>, the temperature below a sintering trolley fire grate is recorded as T, and the temperature of a sintering flue is recorded as T<D>; the flue gas flow of each acquisition device in the sintering process is recorded, the flue gas flow below a sintering trolley fire grate is recorded as V, and the flue gas flow of the sintering flue is recorded as V<D>; and the sintering flue gas atmosphere composition is recorded; step 3, the residual heat retention rate of the sintering machine body is calculated according to the data collected in the step 2; and step 4, field personnel is guided to adjust production parameters according to the residual heat retention rate of the sintering machine. According to the sintering machine residual heat monitoring and adjusting method, monitoring and early warning can be performed on the sintering machine body residual heat in real time, field operators are guided in time to adjust production parameters and replace or maintain equipment; the sintering machine body residual heat is improved, enterprise production energy consumption is reduced, and considerable additional benefits are created.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +2

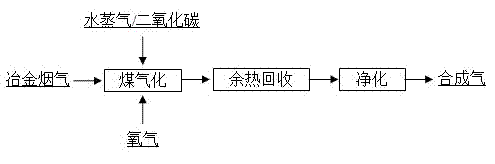

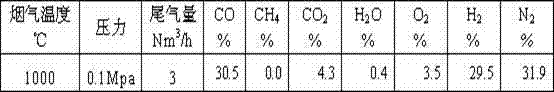

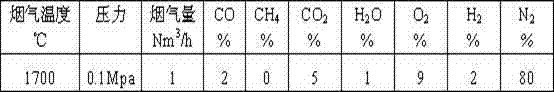

Method for using metallurgical fume for coal gasification

InactiveCN102965153AImprove utilization efficiencyTake advantage of real-time adjustmentsEnergy inputCombined combustion mitigationChemical industryAdditive ingredient

The invention relates to a method for using metallurgical fume for coal gasification, belonging to the fields of metallurgical engineering as well as energy and chemical industry. The method comprises the following steps of: mixing metallurgical fume with a temperature below 600 DEG C with one of vapour and carbon dioxide or both the vapour and the carbon dioxide in any ratio; charging oxygen for support in the case that the temperature of the metallurgical fume is below 800 DEG C; charging the mixed gas in coal and performing a coal gasification reaction; performing waste heat recovery and purification treatment on the tail gas obtained after the coal gasification reaction; and finally obtaining one or two of the purified CO and H2. A real-time adjustment can be performed to utilize the fume with an unstable temperature; combustible ingredients in the fume can be efficiently utilized on the aspects of resource reuse or calorific value increase; and the utilization efficiency of coal can be increased in combination with fume utilization.

Owner:KUNMING UNIV OF SCI & TECH

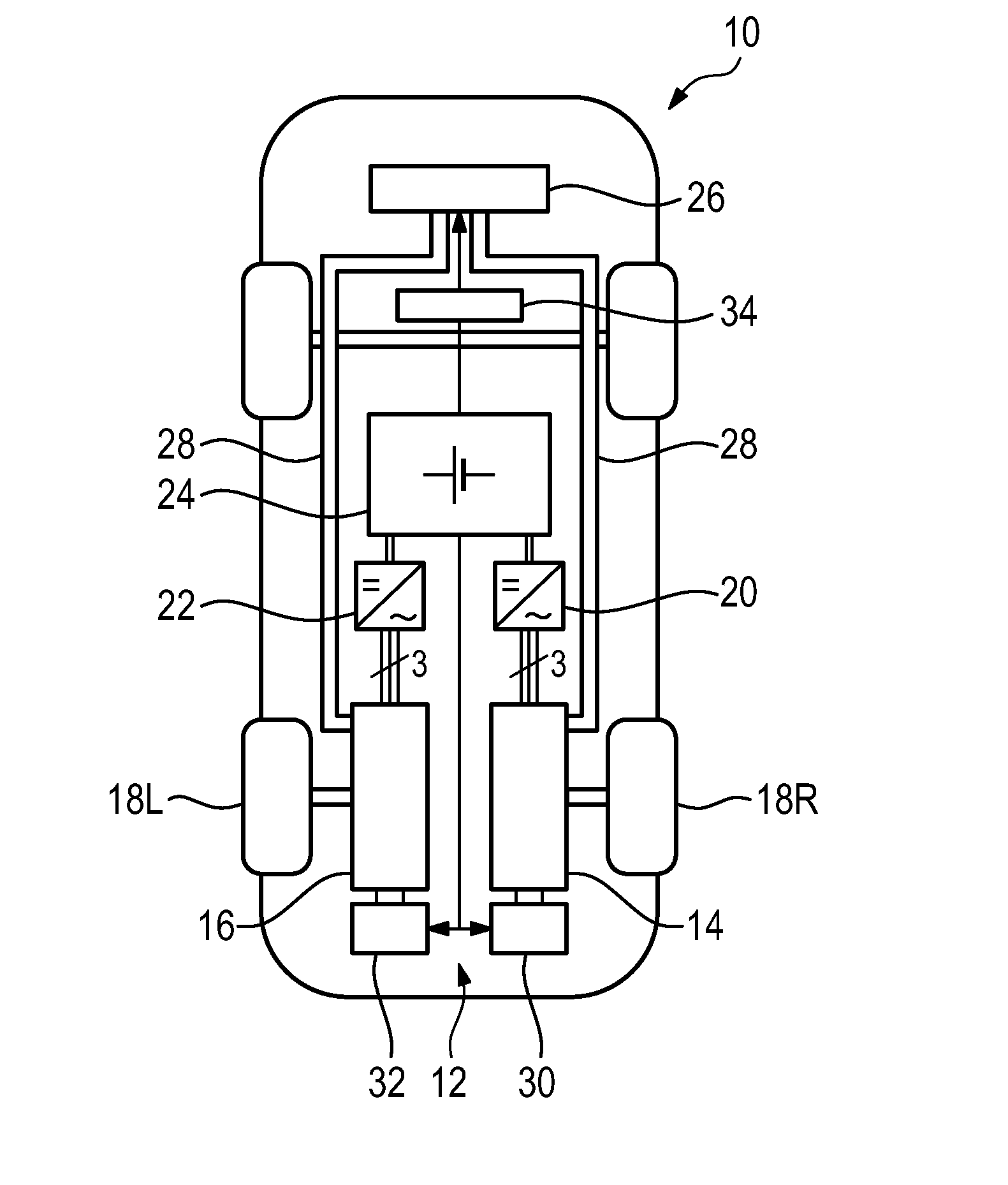

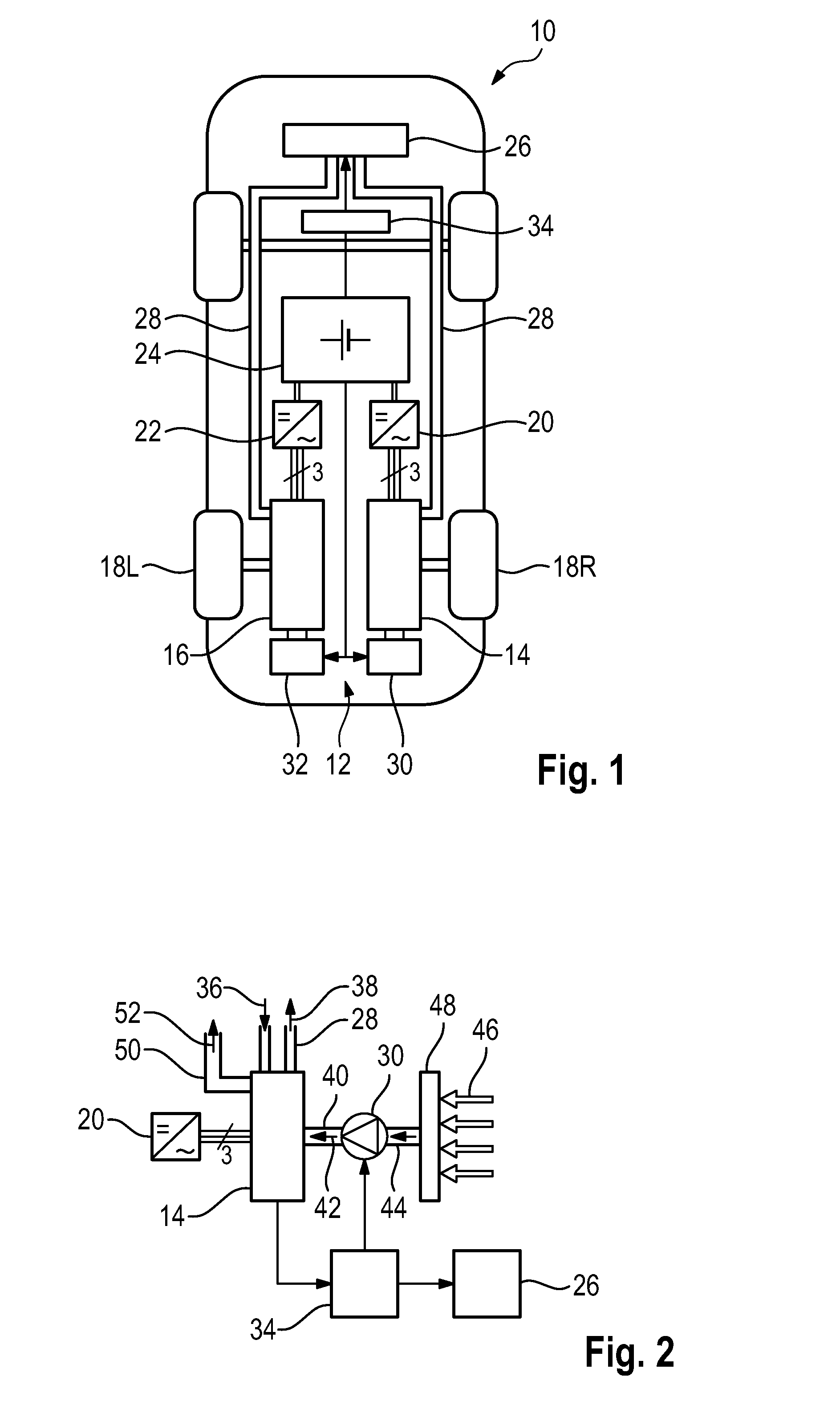

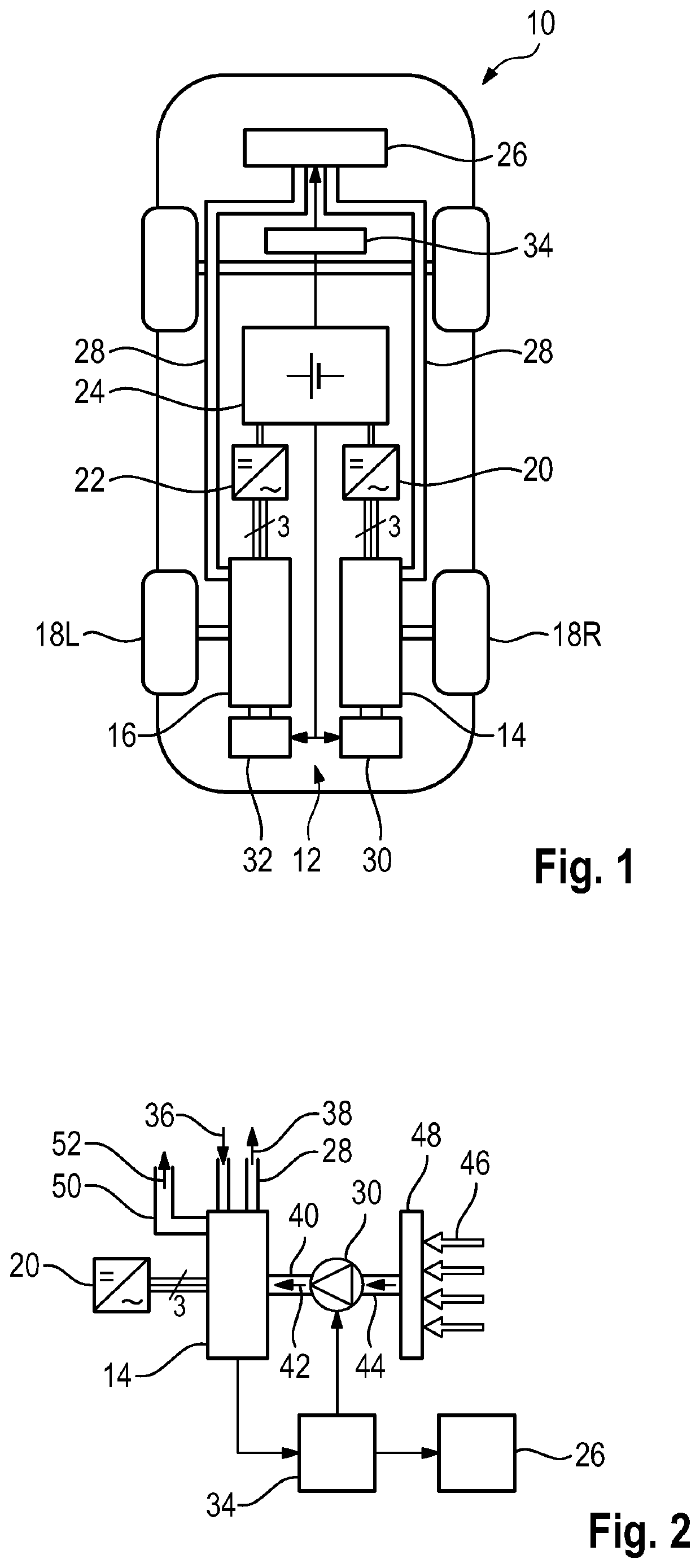

Electric machine for a motor vehicle and method for cooling an electric machine

ActiveUS20150357882A1Little technical complexityReduce complexityAir-treating devicesOther heat production devicesElectric machineMotorized vehicle

An electric machine (14, 16) for a drive train (12) of a motor vehicle (10) has a coil arrangement and a rotor mounted rotatably relative to the coil arrangement. A fluid line is connected thermally to at least one component of the electric machine (14,16) to supply a cooling fluid (36) to the electric machine (14, 16) and to cool the at least one component. A fan (30, 32) is designed to supply cooling air (42) to the electric machine for cooling the electric machine (14, 16), and a control unit (34) controls the fan (30, 32). The control unit (34) controls the fan arrangement (30, 32) and the cooling air supply depending on a speed (n) and / or a torque (M) of the electric machine (14, 16).

Owner:DR ING H C F PORSCHE AG

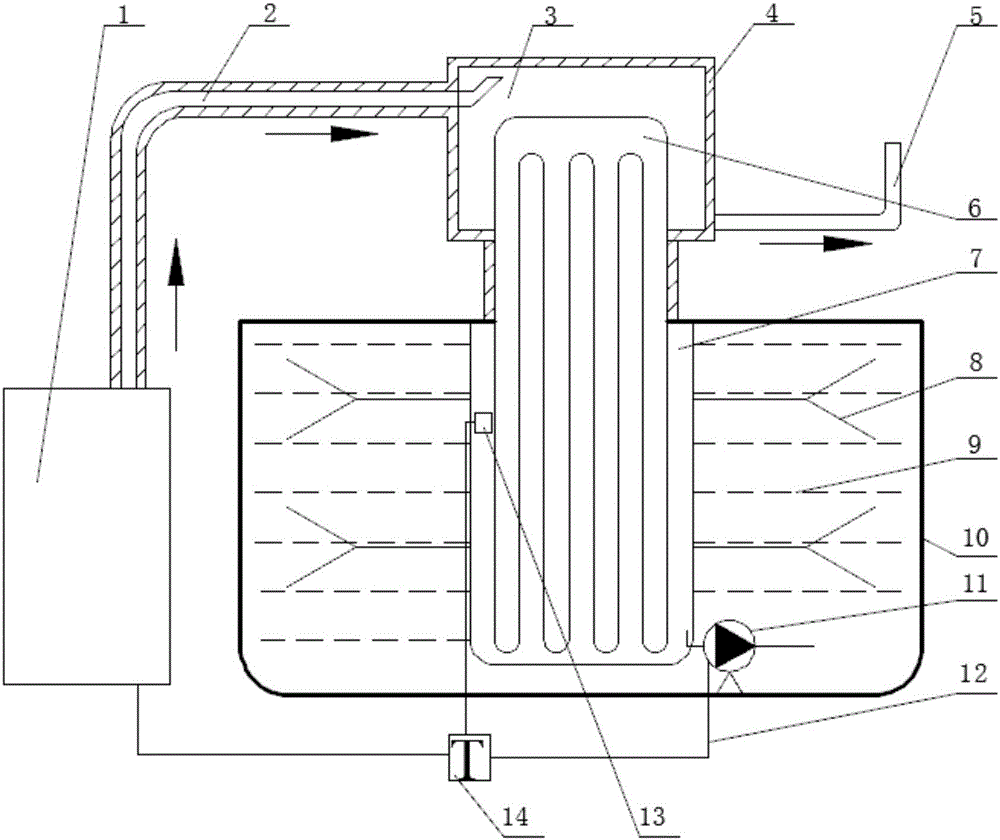

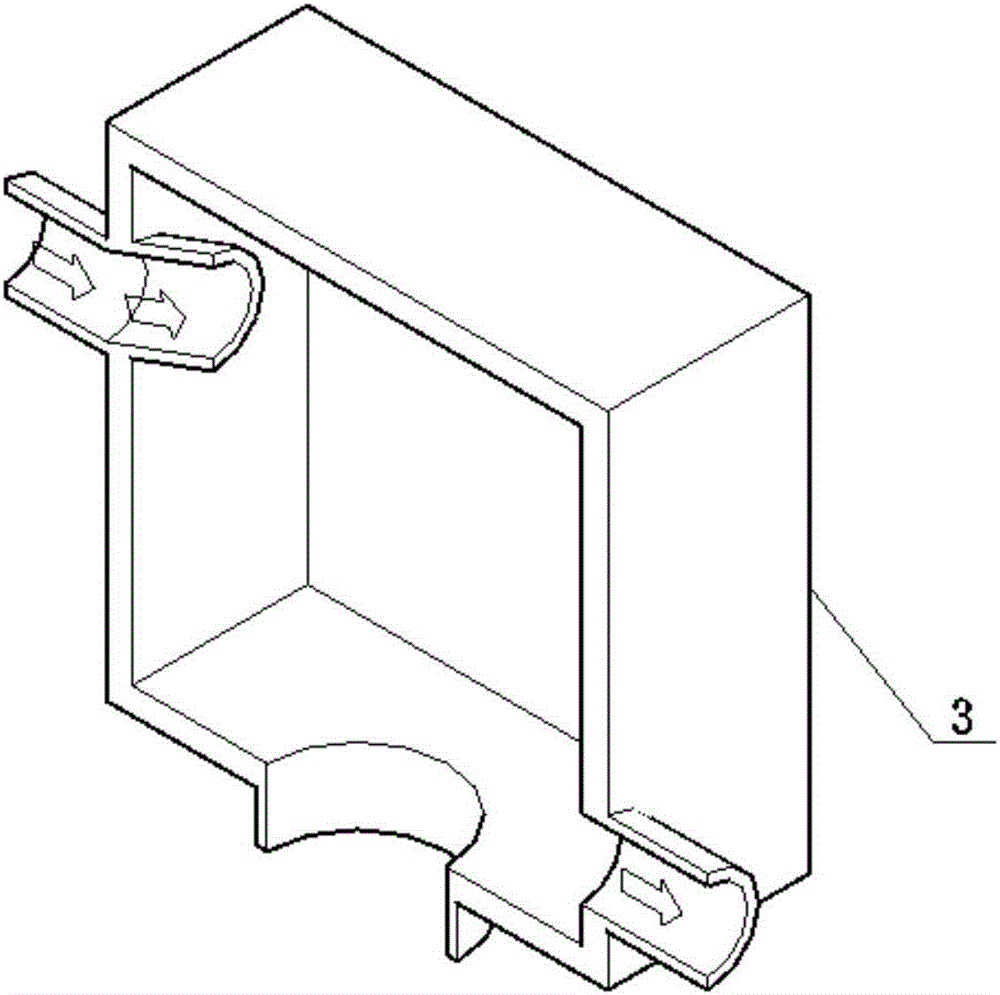

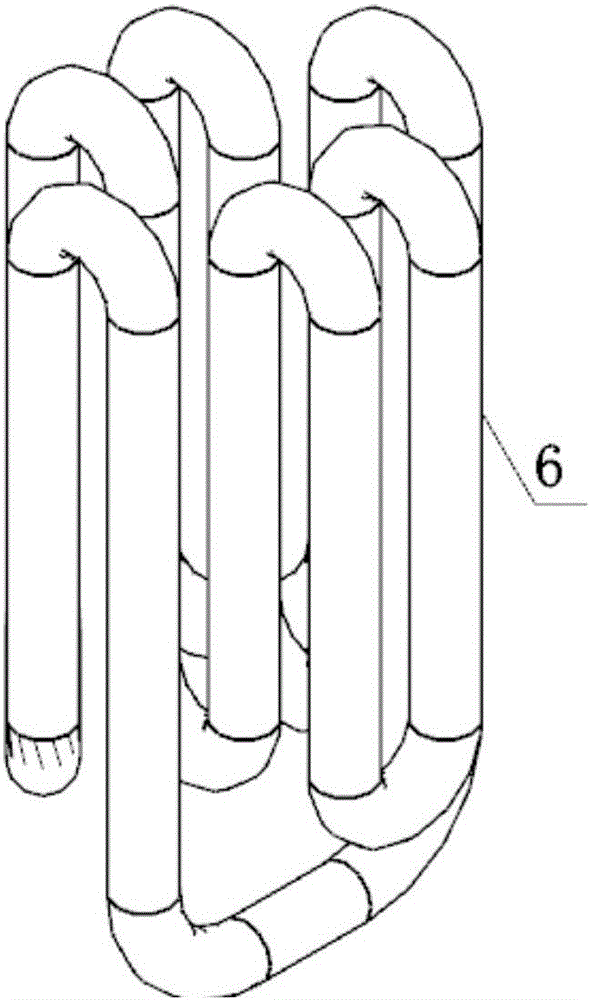

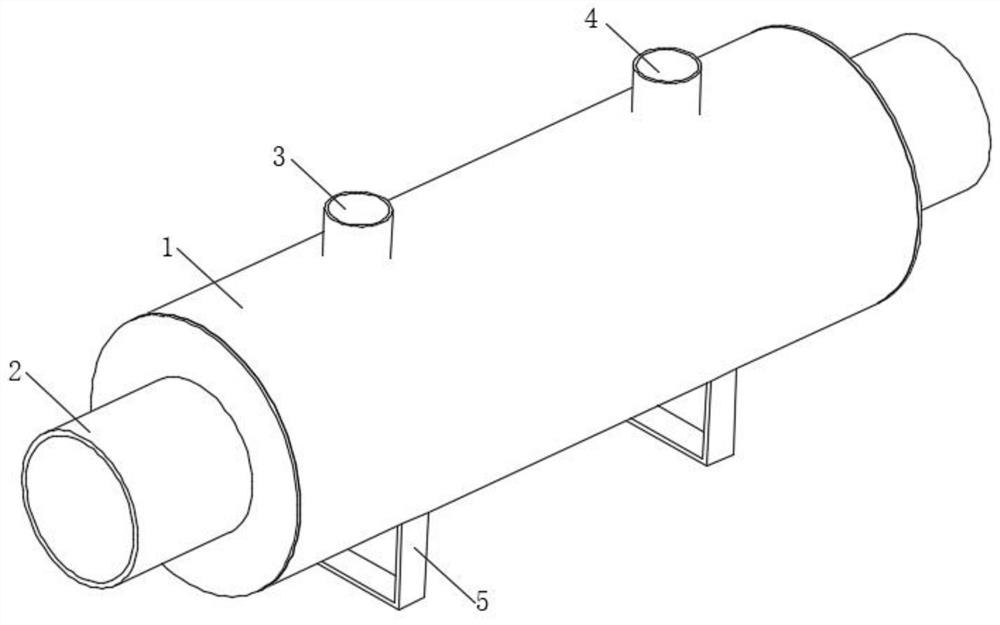

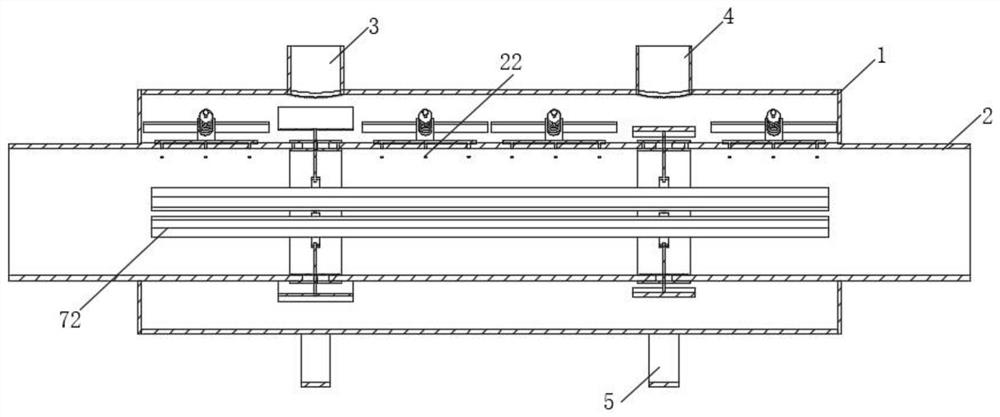

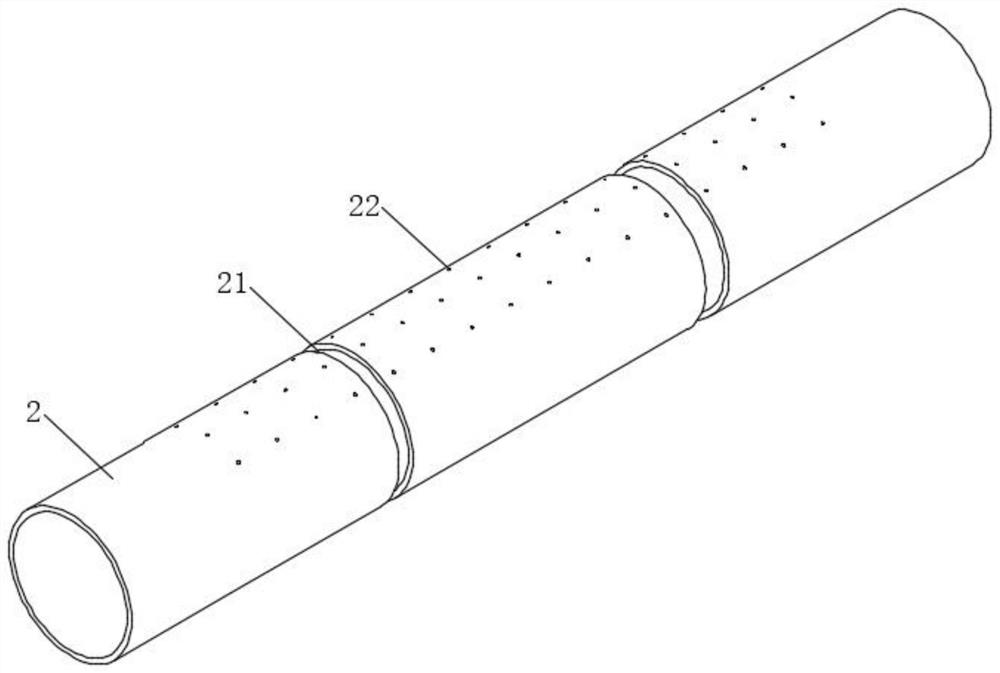

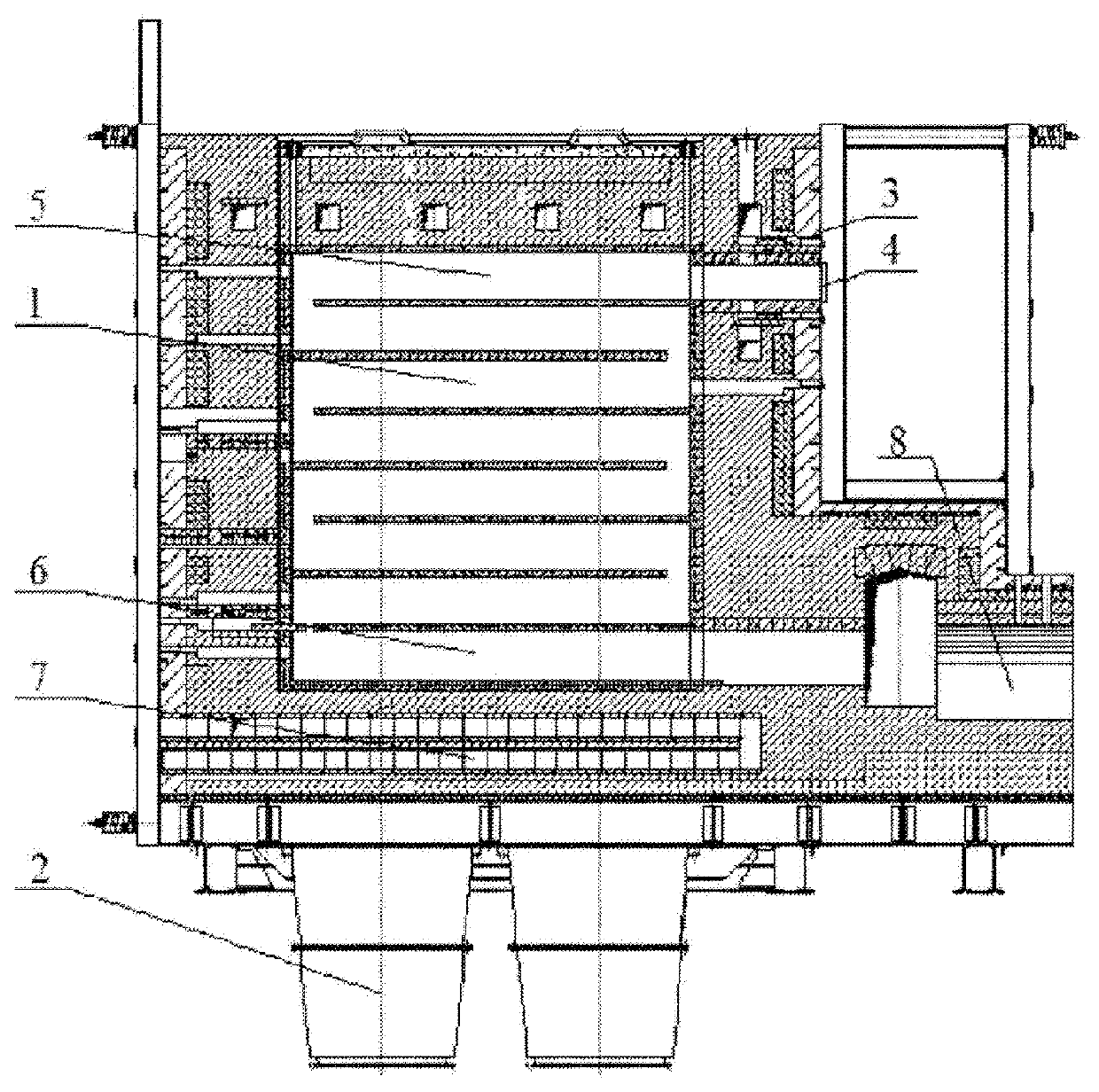

Temperature control device of oil storage system of generator set of polar scientific research station

ActiveCN106246420ARealize the recovery of exhaust heatAvoid uneven temperatureInternal combustion piston enginesExhaust apparatusTemperature controlEngineering

The invention discloses a temperature control device of an oil storage system of a generator set of a polar scientific research station. The temperature control device comprises the generator set and the oil storage system; the generator set comprises an oil inlet and a smoke outlet; and a sleeve is arranged inside the oil storage system, heat exchange rib plates are arranged on the outer wall of the sleeve, a self-circulation heat exchange pipe embedded into the sleeve and attached to a cavity of the sleeve is arranged inside the sleeve, the lower end of the self-circulation heat exchange pipe is located in the oil storage system, the upper end of the self-circulation heat exchange pipe is located in a thermal storage smoke chamber, the self-circulation heat exchange pipe comprises a plurality of vertical pipes and elbows located at the ends of the vertical pipes, the plurality of vertical pipes are connected to form a closed pipe, and the self-circulation heat exchange pipe is filled with phase change working media distributed in the vertical pipes. According to the temperature control device, heat transfer is realized, the heat in smoke discharged by the generator set of the polar scientific research station can be efficiently recycled and can be used for realizing temperature control of the oil storage system of the generator set, and therefore the economical efficiency and the reliability of operation of the generator set are greatly improved in high-altitude and low-temperature environment.

Owner:SOUTHEAST UNIV

Waste heat utilization device based on furnace smoke

InactiveCN113776343AStrong driving forceIncrease profitIncreasing energy efficiencyCombustion technology mitigationThermodynamicsWater flow

The invention relates to the technical field of waste heat utilization equipment, and discloses a waste heat utilization device based on furnace smoke. The waste heat utilization device comprises an outer cavity, a water flowing pipeline is arranged at the center axis of the interior of the outer cavity, the water flowing pipeline penetrates through the left side wall and the right side wall of the outer cavity and extends to the outside, a smoke inlet pipeline is arranged at the top of the left side of the outer cavity, the smoke inlet pipeline communicates with the outer cavity, and one end, away from the smoke inlet pipeline, of the top of the outer cavity is provided with a smoke outlet pipeline in a communicating mode. According to the waste heat utilization device based on the furnace smoke, when a large amount of furnace smoke passes through the smoke inlet pipeline, due to the fact that the moving area is reduced, the pushing force of the furnace smoke can be increased, an arc-shaped flow guide plate can drive a rotating ring to rotate under the action of the pushing force of the furnace smoke, rotation of the rotating ring can drive an internal stirring plate to rotate, therefore, cold water can be stirred by the stirring plate, the contact area of the cold water and the furnace smoke is increased, and the utilization rate of furnace smoke waste heat is increased.

Owner:何谦

Laser amplifier and method of making the same

ActiveUS7627017B2Improve power performanceIncrease waste heatSemiconductor/solid-state device manufacturingOptical resonator shape and constructionAudio power amplifierTotal internal reflection

The present invention includes a laser amplifier and a method of making the same. The laser amplifier of the present invention includes a gain medium layer having a first index of refraction, and a coupling layer optically coupled to the gain medium. In the various embodiments described herein, the coupling layer can have a second index of refraction less than the first index of refraction. The laser amplifier described herein can also include an evanescent layer disposed between the gain medium and the coupling layer. The evanescent layer can have a third index of refraction less than the second index of refraction. The laser amplifier provides high power, efficient laser resonance through frustrated total internal reflection and total internal reflection while simultaneously providing for the minimization of waste heat in the gain medium layer.

Owner:STC UNM

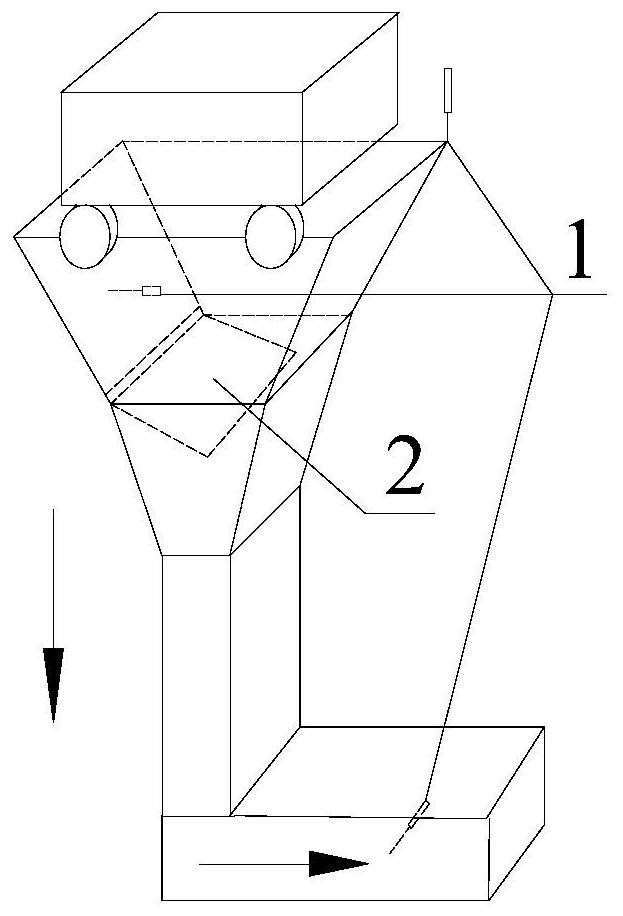

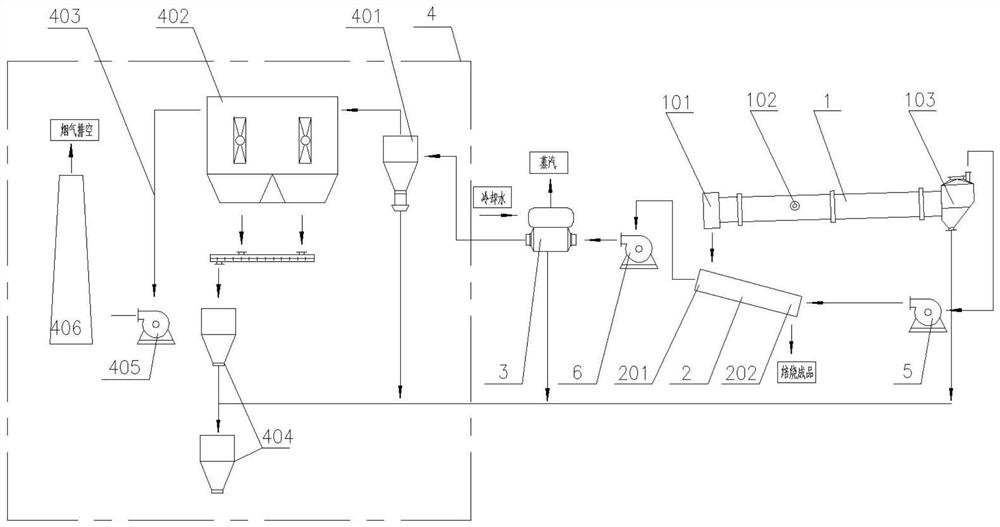

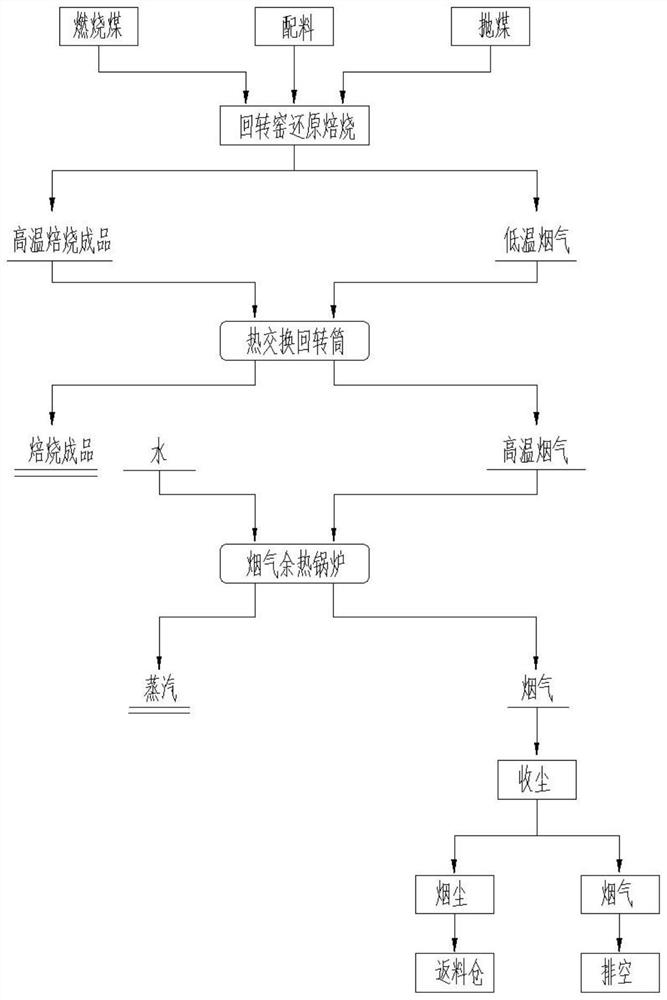

Reducing roasting flue gas and roasting finished product waste heat comprehensive recovery device and method

InactiveCN111623641AAchieve recyclabilityIncrease waste heatIncreasing energy efficiencySteam generation using hot heat carriersFlue gasProcess engineering

The invention discloses a reducing roasting flue gas and roasting finished product waste heat comprehensive recovery device and method. The device comprises a reducing roasting rotary kiln, a heat exchange rotary cylinder, a flue gas waste heat boiler and a flue gas post-processing system, wherein the heat exchange rotary cylinder is arranged obliquely, the front end of a cylinder body is higher than the rear end of the cylinder body, the front end of the cylinder body communicates with a discharge port of a kiln head of the reducing roasting rotary kiln, the rear end of the cylinder body communicates with a kiln tail flue gas outlet of the reducing roasting rotary kiln, the communication is used for reducing roasting low-temperature flue gas and a high-temperature roasting product for heat exchanging in the cylinder, the flue gas waste heat boiler communicates with the front end of the heat exchange rotary cylinder body and is used for producing steam by using the waste heat of flue gas, and the flue gas post-processing system communicates with the flue gas waste heat boiler and is used for removing dust and cooling. The device and the method comprehensively recover the reductionroasting low-temperature flue gas waste heat and the roasted finished product waste heat to produce the steam, the steam can be used for subsequent power generation, heating in the production processor domestic heating, and the purposes of effective recovery of secondary energy, energy saving and emission reduction are achieved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

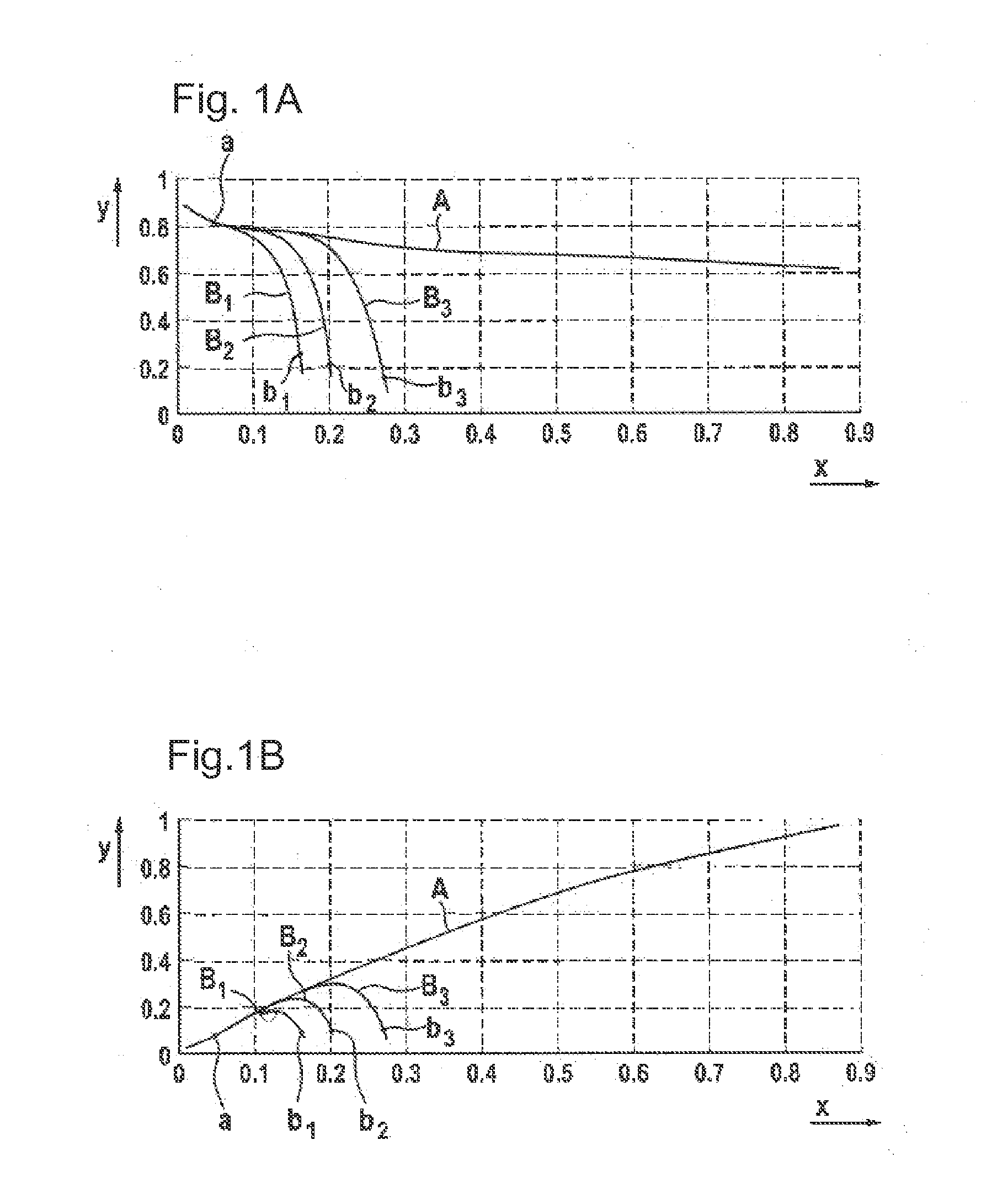

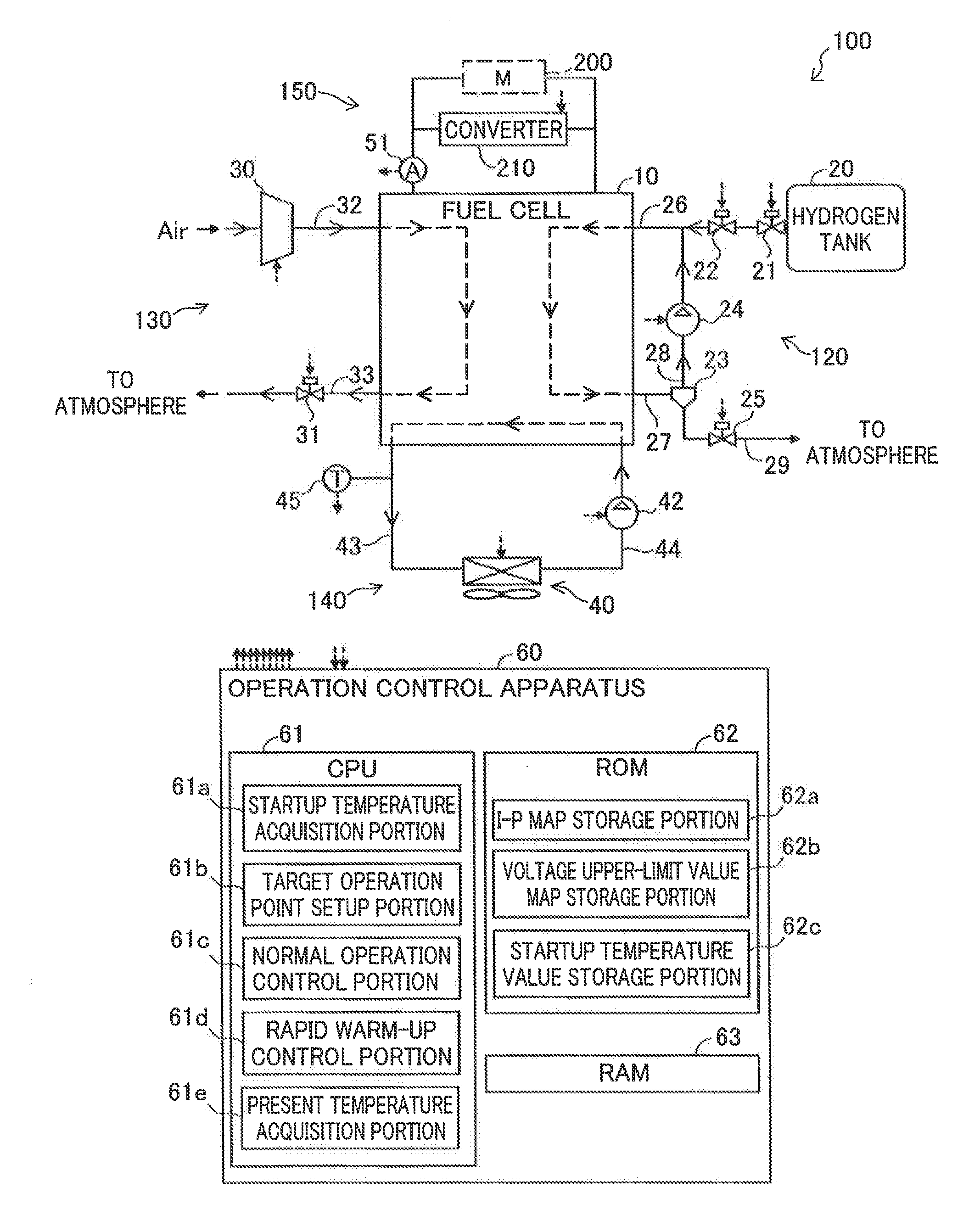

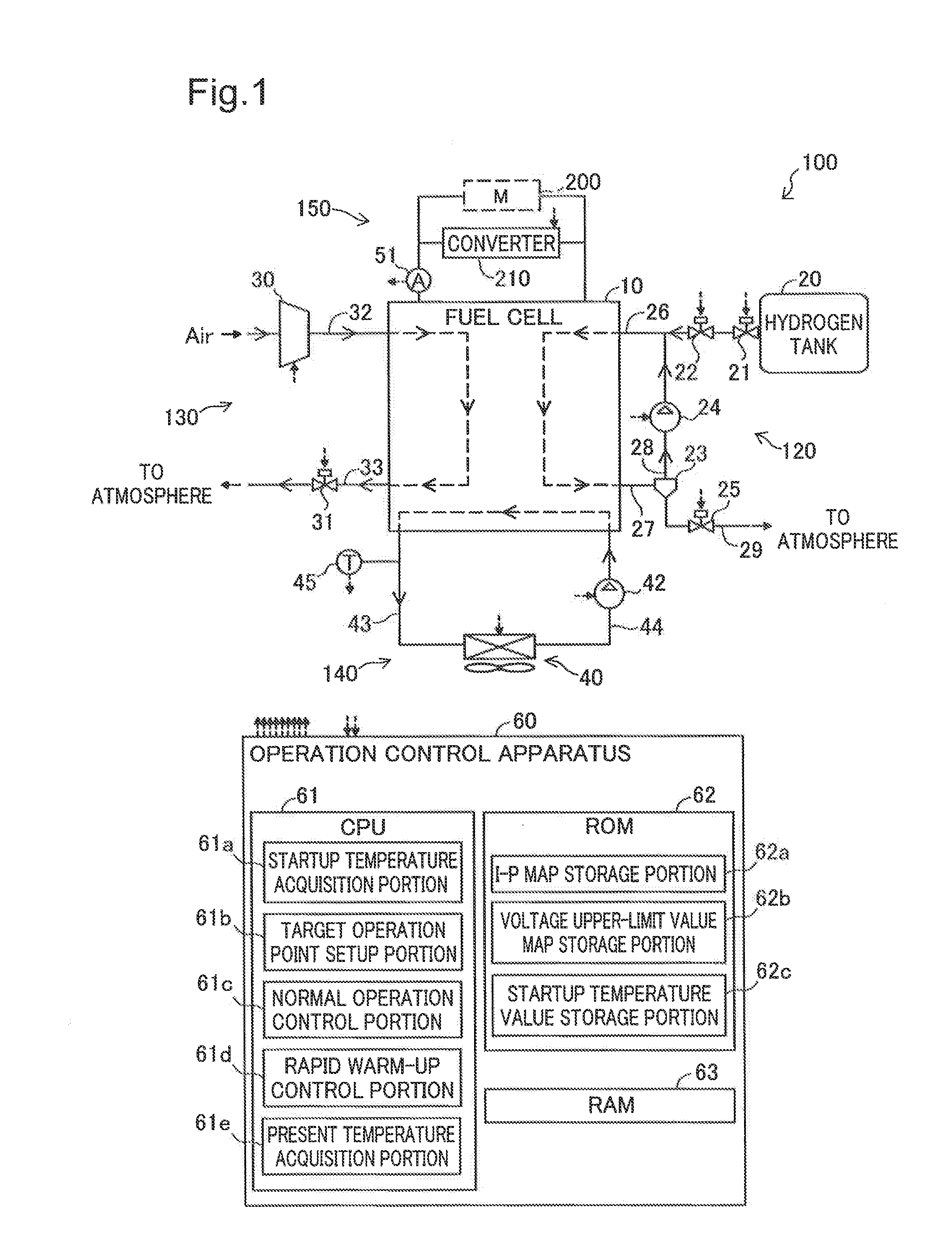

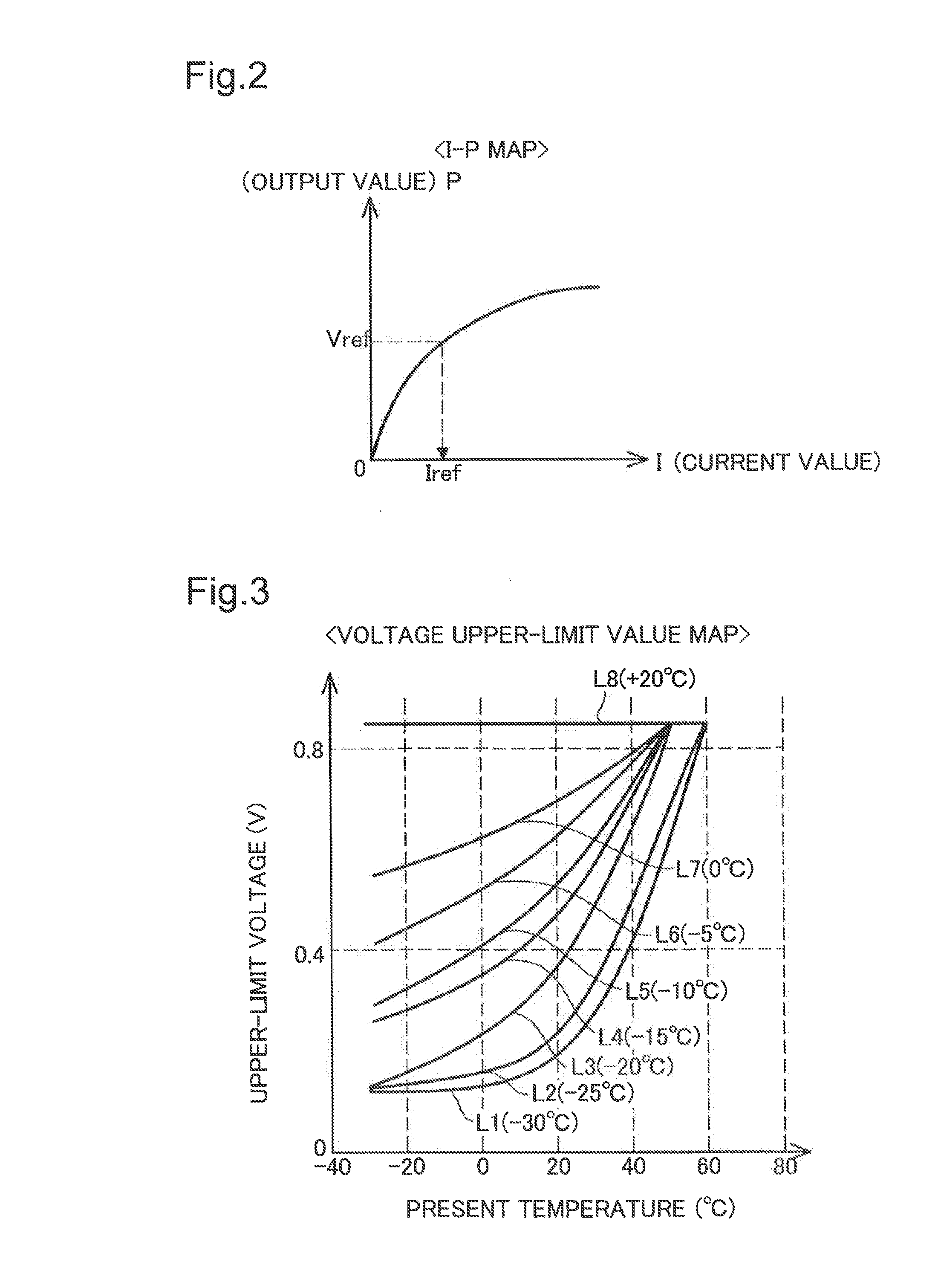

Operation control method of fuel cell and operation control apparatus of fuel cell

ActiveUS20160133967A1Reduce amount of waterAmount of heat be wasteFuel cell controlBattery/fuel cell control arrangementVoltageGas supply

The operation control method of a fuel cell includes acquiring a startup temperature of the fuel cell; acquiring a present temperature of the fuel cell; setting a present target operation point of the fuel cell that is identified by an output voltage value and an output current value based on the startup temperature, or based on the startup temperature and the present temperature; controlling at least one of the flow of the reaction gas supplied to the fuel cell, and an output voltage of the fuel cell so that the operation point of the fuel cell becomes the target operation point, and setting the target operation point includes a process of setting an operation point having a low output voltage value as the target operation point when the startup temperature is low as compared to the case when the startup temperature is high, if the present temperature is the same.

Owner:TOYOTA JIDOSHA KK

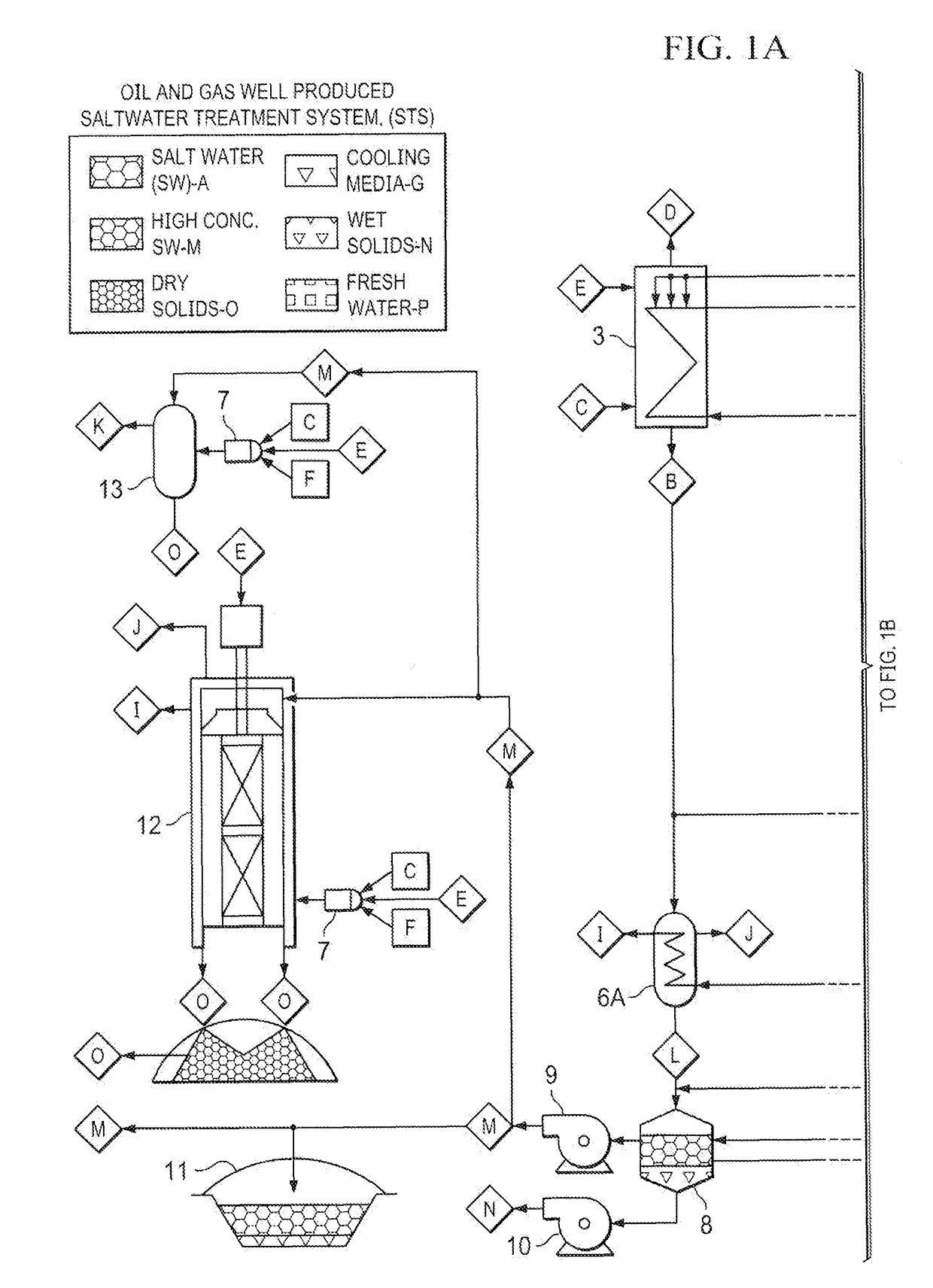

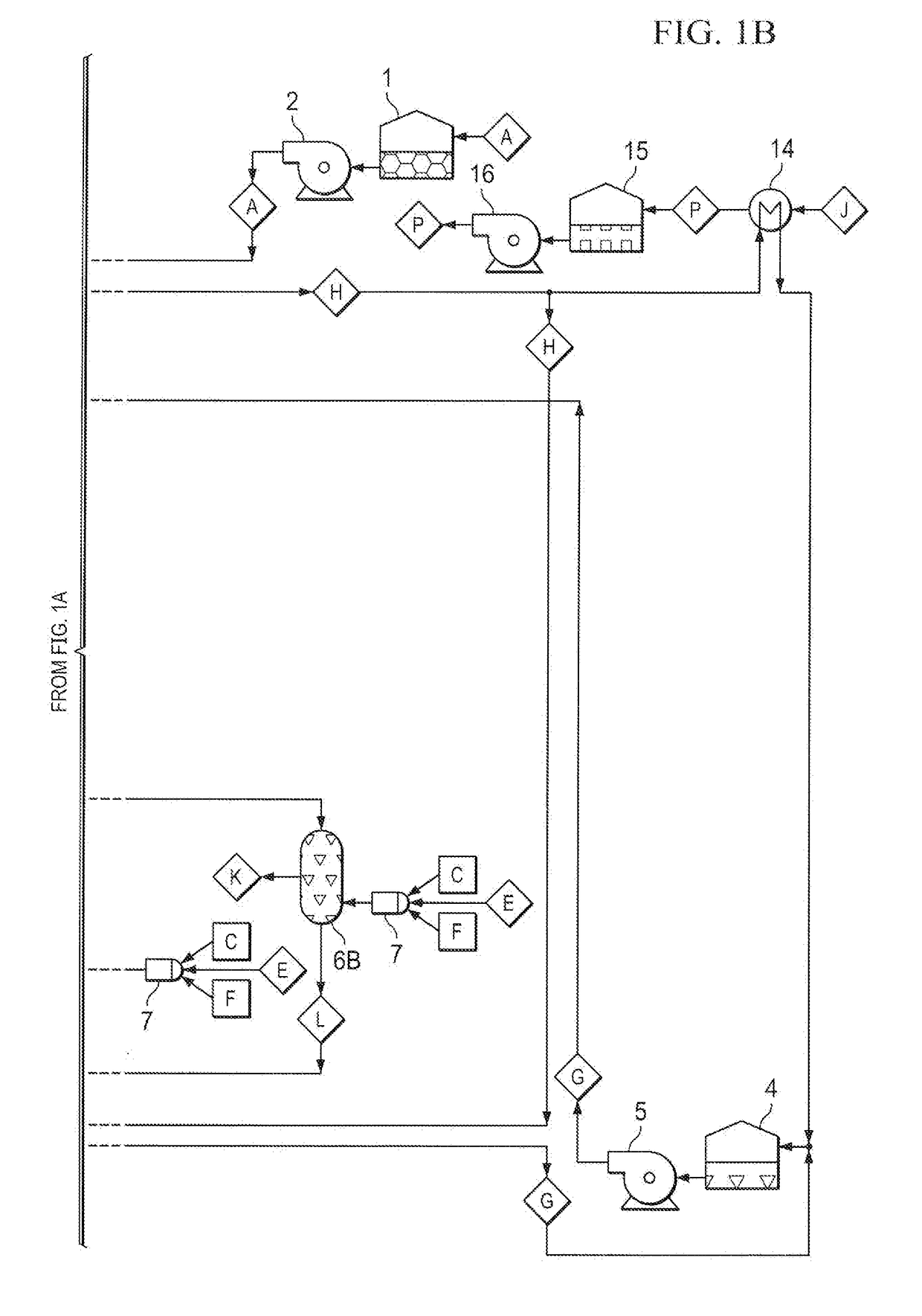

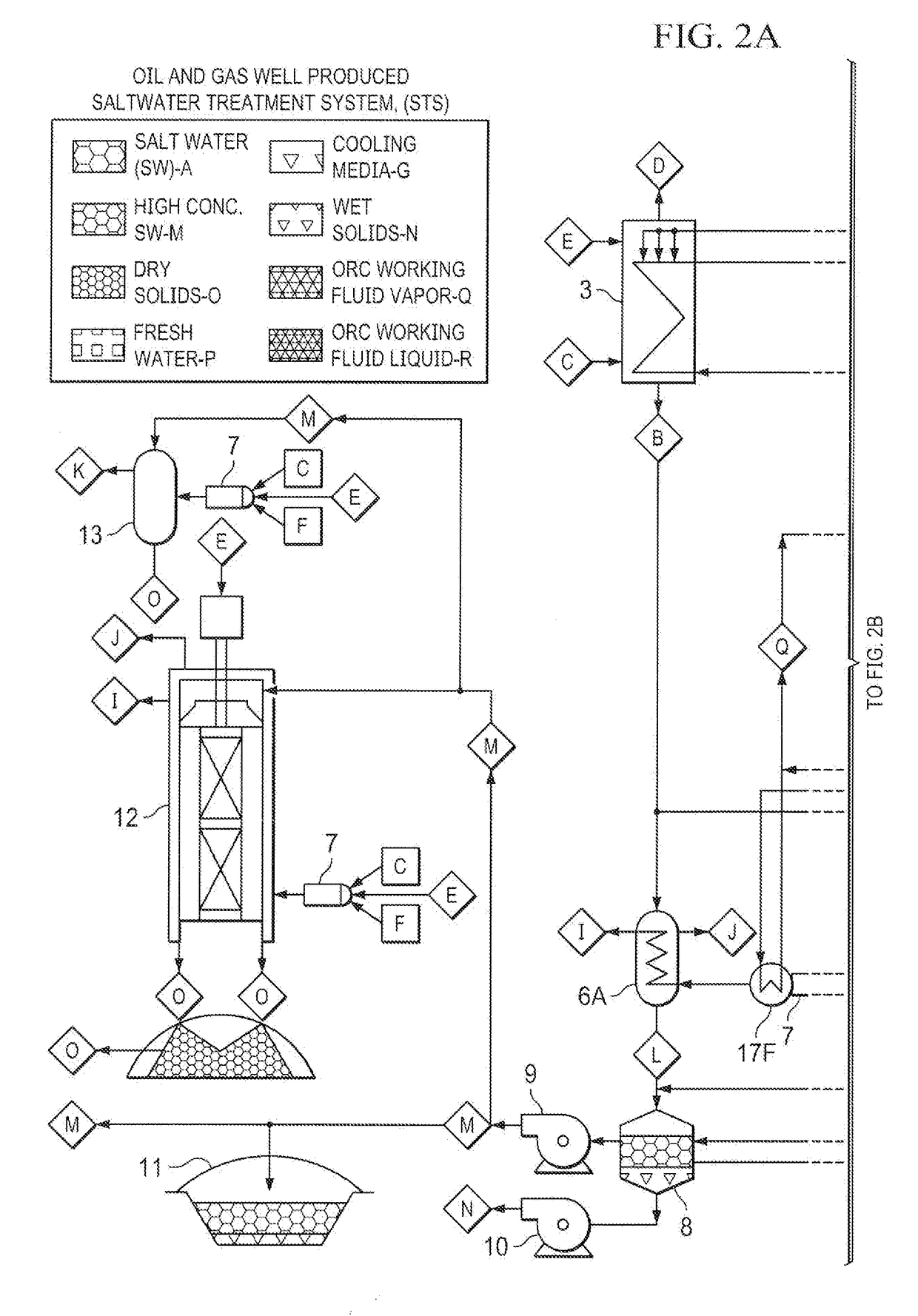

Oil and gas well produced saltwater treatment system

ActiveUS20190048701A1Cost-effectiveAid removalExhaust apparatusSpecific water treatment objectivesSaline waterEnvironmental engineering

An integrated process which simultaneously removes water and precipitated salts from oil and gas well produced saltwater, thus reducing or eliminating the cost and environmental problems associated with waste water disposal, while adding revenue through electrical production and other coproducts. The addition of a zero emissions engine will also convert wellhead natural gas into carbon neutral, emission free electrical and thermal energy, along with facilitating additional products further reducing the cost of processing the saltwater.

Owner:MOORE JOE TRAVIS

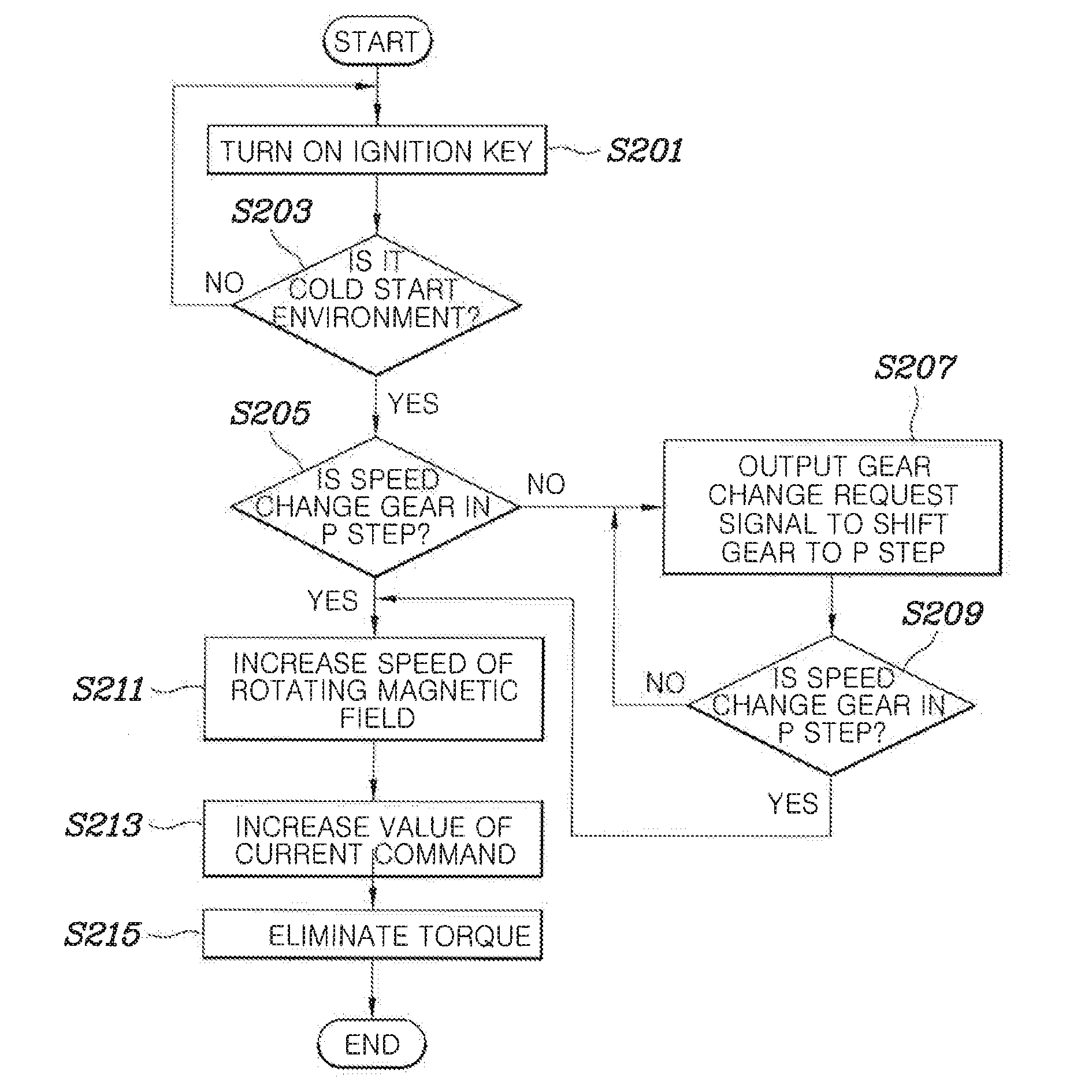

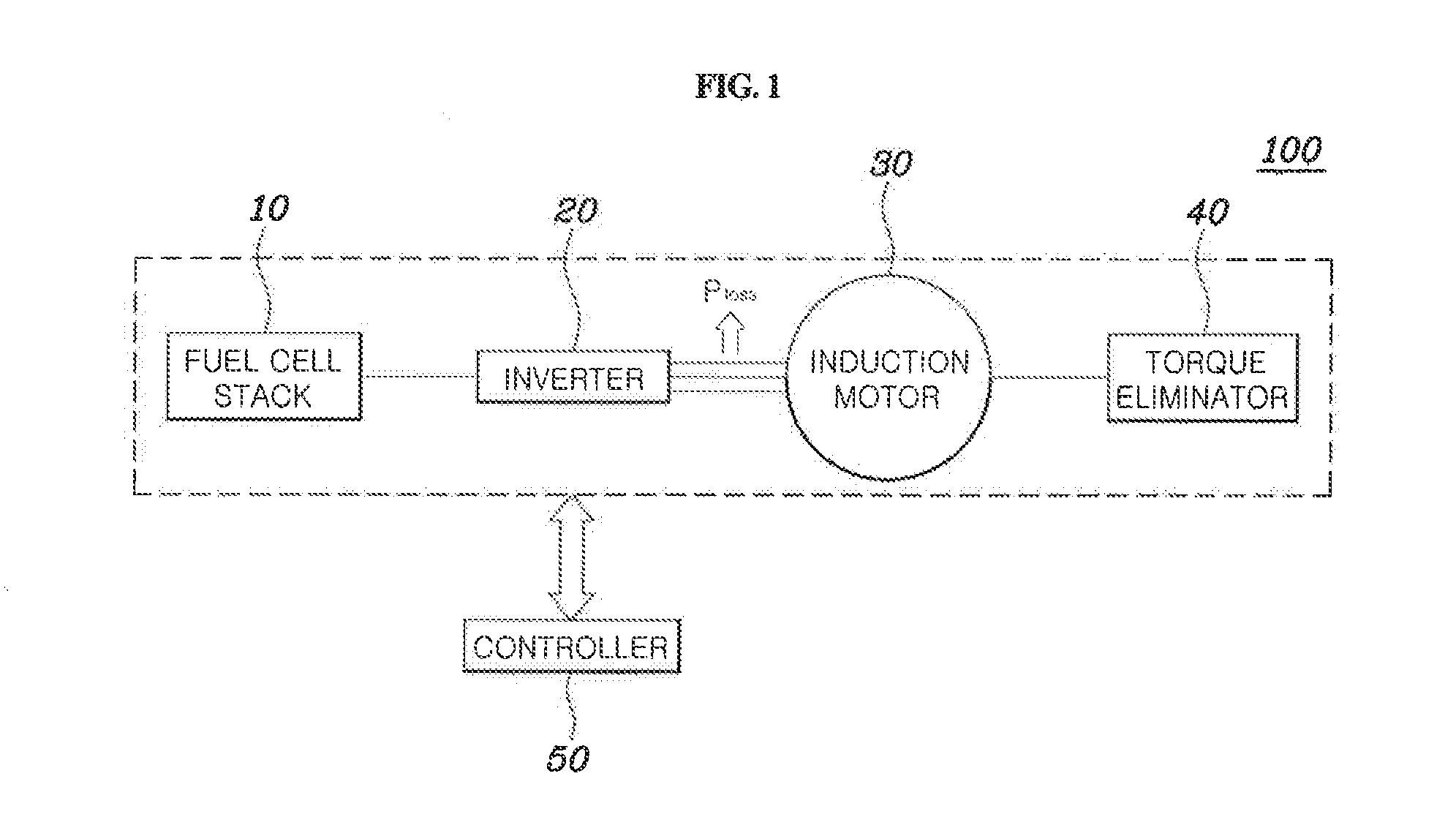

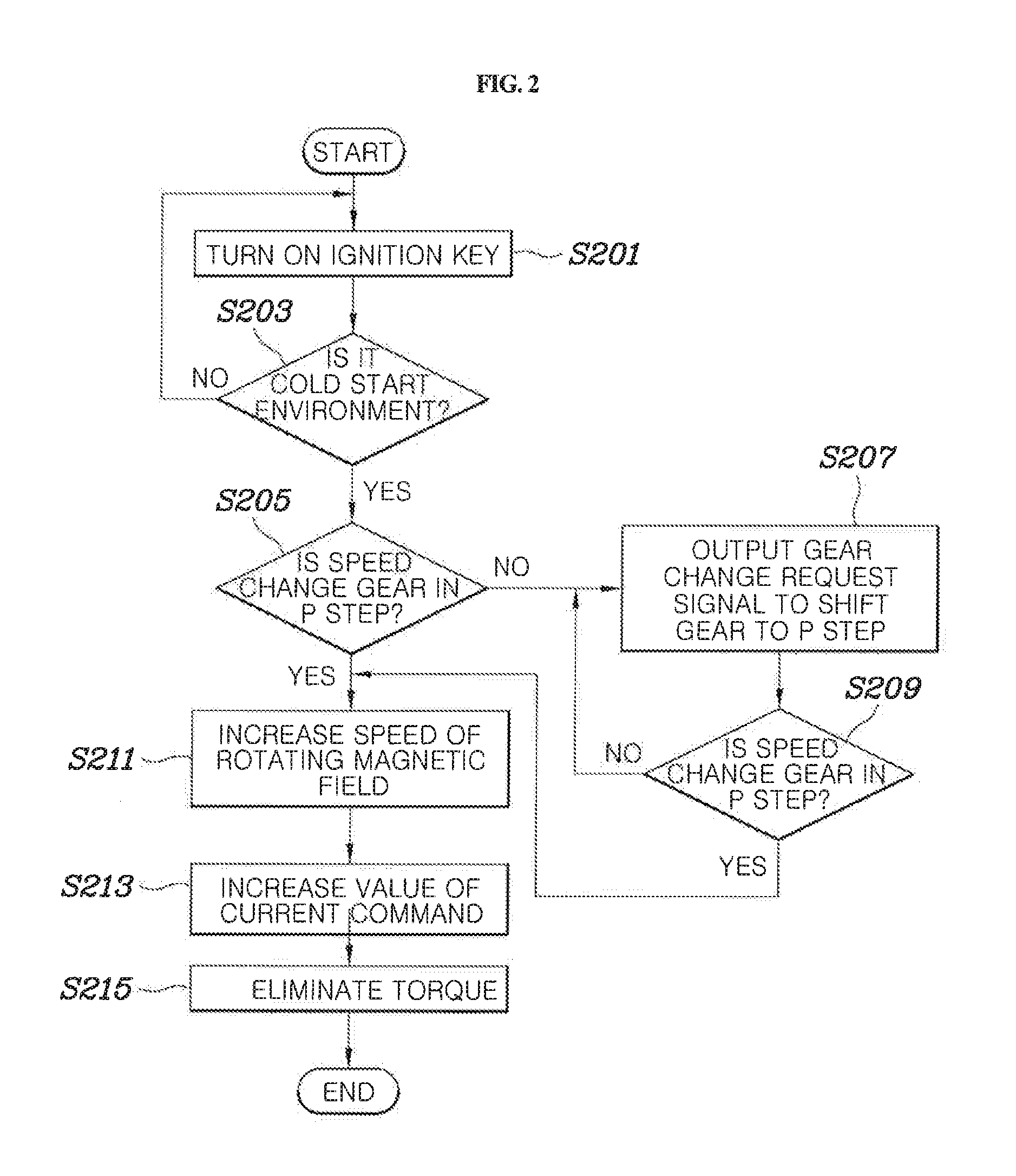

Fuel cell system and method for controlling the same

ActiveUS20150364776A1Increase fuel temperatureQuick upgradeOperating modesFuel cell controlFuel cellsInduction motor

A fuel cell system and a method tor controlling the same are provided. The method includes rapidly increasing an angular speed of a rotating magnetic field of an induction motor to maximize iron loss of the induction motor, thereby resulting in an increase in the temperature of a rise cell stack. The method further includes eliminating torque of a driving motor generated by an increase in the angular speed of the rotating magnetic field, using a torque eliminator. The torque eliminator includes a P-stage reducer or a hydraulic break.

Owner:HYUNDAI MOTOR CO LTD

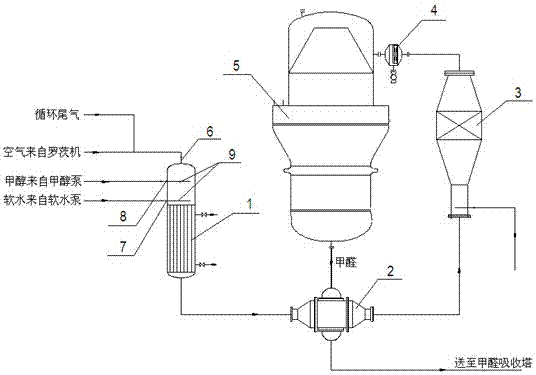

A methanol evaporation oxidation process device for the production of formaldehyde by silver method

InactiveCN104693015BEfficient productionReduce production energy consumptionOrganic compound preparationCarbonyl compound preparationFlame arresterEvaporation

The invention discloses a methanol evaporation and oxidation process device for production of silver-method methanal. The methanol evaporation and oxidation process device for production of silver-method methanal comprises a vaporizer mixer, a superheater, a filter, a flame arrester and an oxidizer, wherein the vaporizer mixer is a tube sheet heat exchanger; an upper end cover of the tube sheet heat exchanger is an atomization space; an air inlet is formed in the top of the atomization space; a methanol inlet and a soft water inlet are formed in the lateral wall of the atomization space and connected with atomization nozzles; air is mixed with atomized methanol and water gas and then enters the tube pass of the heat exchanger; a hot source circulates in the shell pass of the heat exchanger; an outlet of the tube pass of the heat exchanger is sequentially connected with inlets of the superheater, the filter, the flame arrester and the oxidizer. An air blower is not needed, and air resistance does not exist; meanwhile, after the novel process is adopted, the utilization rate of waste heat is greatly increased, the cooling loads are much lower than the cooling loads of cooling water of one tower of methanal in an old process, and the old process increases the usage amount of cooling water.

Owner:JIANGSU KAIMAO PETROCHEM TECH

Pot furnace low-temperature calcination process

ActiveUS11306254B2Reduce the amount requiredReduce corrosionSolid fuelsEnergy inputThermodynamicsProcess engineering

A pot furnace low-temperature calcination process may ensure that, by controlling the flame path temperature and discharge speed of the pot furnace, that the range of the temperature at which the petroleum coke is calcined in the pot is from 1150° C. to 1220° C., and that the discharge speed is 10 to 20% higher than the normal discharge speed and reaches 110˜120 kg / h, reducing the amount of desulfurization of the petroleum coke during the calcination so that the true density of the calcined coke is between 2.05 and 2.07 g / cm3.

Owner:CHINA ALUMINUM INT ENG CORP

Energy-saving gas stove

ActiveCN102620321BIncrease profitImprove gas utilizationDomestic stoves or rangesLighting and heating apparatusHearthEngineering

Owner:GUANGDONG HENGLIAN FOOD MACHINERY

Powder blowing lance and method for refining molten iron using the powder blowing lance

ActiveCN103890199BReduce distractionsImprove heat transfer efficiencyManufacturing convertersElectric furnaceMetallurgyEngineering

A powder blowing lance comprising a refining oxygen blowing nozzle and a burner, the refining oxygen blowing nozzle having a plurality of blowing openings, the plurality of blowing openings being spaced apart along a circular track Arranged to blow oxygen into the iron bath accommodated in the reaction vessel through the plurality of ejection openings, the ejection nozzles have ejection openings, and the ejection openings have a center axis coaxial with the circular rail. The shaft core of the shaft forms a flame inside the oxygen injection nozzle for refining, and blows the powder heated by the flame into the iron bath through the ejection opening, indicating the oxygen for refining The index A of the positional relationship between the discharge opening of the injection nozzle and the discharge opening of the injection burner satisfies A=1.7(R-r-d / 2) / L+tan(θ-12°)-0.0524>0. Here, R: the radius (mm) of the above-mentioned circular orbit, r: the radius (mm) of the discharge opening of the injection burner, d: the diameter (mm) of the discharge opening of the oxygen nozzle for refining, θ: for refining The inclination angle (°) of the shaft core of the oxygen blown into the nozzle, L: the height of the spray gun (mm). As a result, the heat imparting efficiency to the molten iron is improved.

Owner:JFE STEEL CORP

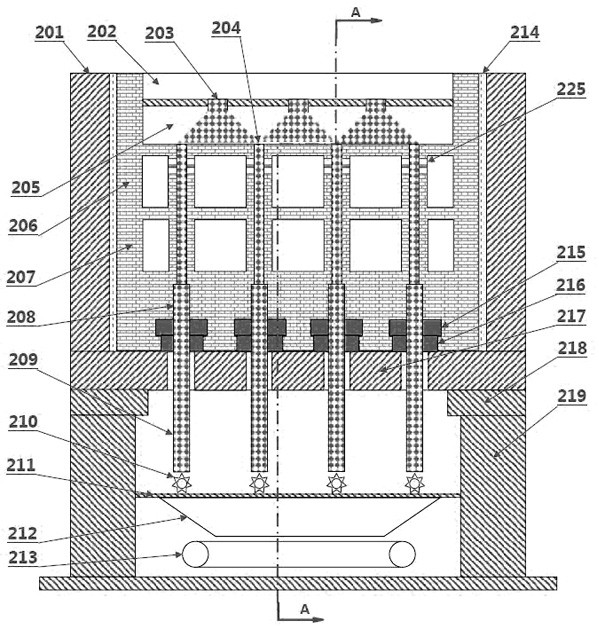

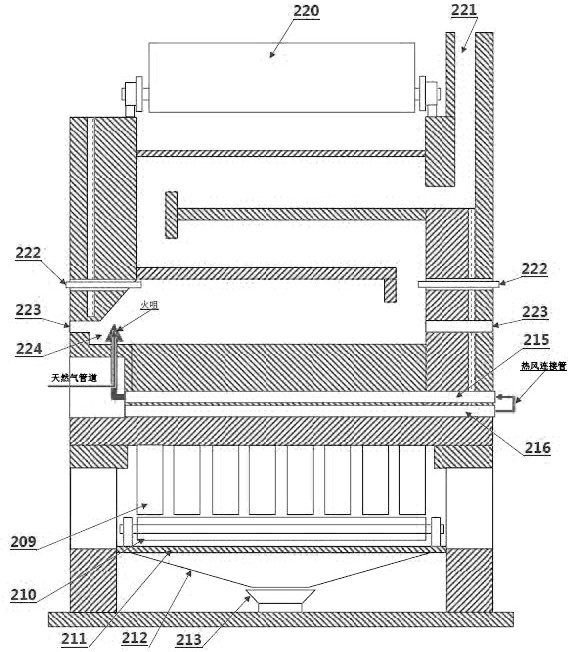

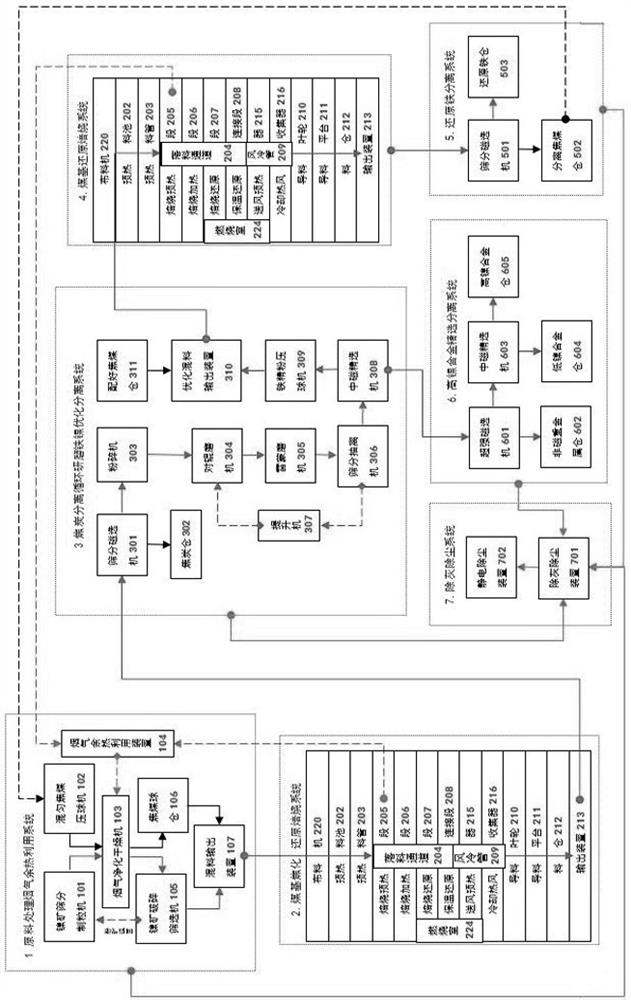

Method and device for producing high-nickel alloy and reduced iron through coal-based coking magnetic separation

PendingCN113957246AEffective in removing harmful impuritiesSignificant comprehensive benefitsWaste heat treatmentFlue gasCoke

The invention relates to the technical field of energy-saving comprehensive utilization of mineral resources, in particular to a method and device for producing high-nickel alloy and reduced iron through coal-based coking magnetic separation. The device comprises a raw material treatment flue gas waste heat utilization system, a coal-based coking reduction roasting system, a coke separation circulating grinding iron-nickel optimization separation system, a coal-based reduction roasting system, a reduced iron separation system, a high-nickel alloy concentration separation system and an ash and dust removal system. Coke is obtained through raw material treatment, coal-based coking reduction roasting and screening magnetic separation, a reduced iron product is obtained through circular grinding and iron-nickel optimization separation, coal-based reduction roasting and coking coal separation, and a high-nickel alloy product is finally left after non-magnetic heavy metal separation and low-nickel alloy separation. The method is suitable for treating laterite-nickel ore with Ni greater than 0.6% and Fe greater than 38%, coked reduced iron and nickel are optimally separated and upgraded respectively, the nickel grade of high-nickel alloy is greater than 11%, the grade of reduced iron is greater than 94%, and the nickel recovery rate is greater than 95%; and the problems of high energy consumption, difficult thermotechnical control and unstable product quality of an existing process for treating the low-grade laterite-nickel ore are solved.

Owner:张雷

Electric machine for a motor vehicle and method for cooling an electric machine

ActiveUS11190084B2Increase waste heatPeak loadingAir-treating devicesElectric propulsion mountingElectric machineRotor (electric)

An electric machine (14, 16) for a drive train (12) of a motor vehicle (10) has a coil arrangement and a rotor mounted rotatably relative to the coil arrangement. A fluid line is connected thermally to at least one component of the electric machine (14,16) to supply a cooling fluid (36) to the electric machine (14, 16) and to cool the at least one component. A fan (30, 32) is designed to supply cooling air (42) to the electric machine for cooling the electric machine (14, 16), and a control unit (34) controls the fan (30, 32). The control unit (34) controls the fan arrangement (30, 32) and the cooling air supply depending on a speed (n) and / or a torque (M) of the electric machine (14, 16).

Owner:DR ING H C F PORSCHE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com