High-temperature neutral blowoff high-efficiency anaerobic fermentation apparatus and fermentation method

An anaerobic fermentation and anaerobic fermentation tank technology, which is applied in the field of high-temperature neutral stripping and high-efficiency anaerobic fermentation devices, can solve the problems of nitrogen pollution in biogas liquid and difficulty in discharging high pH biogas liquid, avoid operating costs, and strengthen biogas liquid. The effect of liquid recycling and ensuring stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

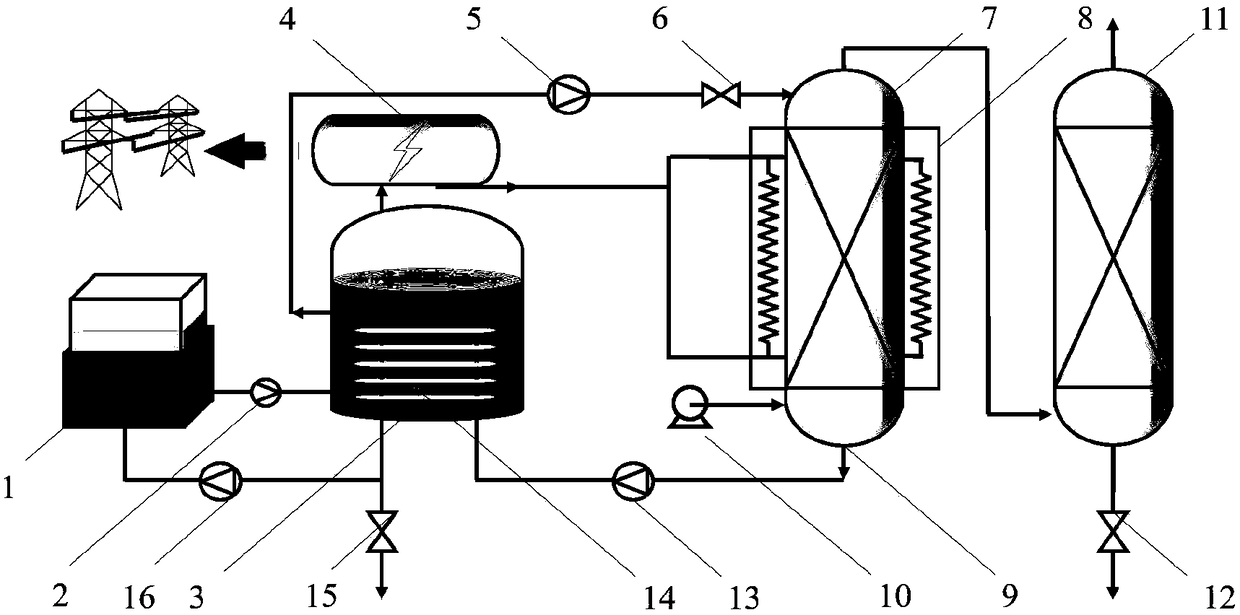

[0029] Example 1 A high-temperature neutral blow-off high-efficiency anaerobic fermentation device

[0030] This embodiment provides a high-temperature neutral blow-off high-efficiency anaerobic fermentation device, such as figure 1 As shown, it includes the raw material premixing tank 1, the anaerobic fermentation tank 3, and the biogas slurry stripping system connected in sequence;

[0031] The biogas slurry stripping system includes a stripping tower 7, an ammonia absorption tower 11 and a heating system 8 for heating the stripping tower;

[0032] The biogas outlet of the anaerobic fermentation tank is connected to the generator 4, and the waste heat collection device located outside the generator is connected to the heating system 8 for transporting the waste heat generated by the generator 4 during operation to the heating system 8 middle.

[0033] The biogas slurry outlet of the anaerobic fermentation tank 1 is connected with the liquid inlet (feed valve) 6 of the stri...

Embodiment 2

[0035] Embodiment 2 A kind of high-temperature neutral stripping high-efficiency anaerobic fermentation method

[0036] This embodiment provides a high-temperature neutral blow-off high-efficiency anaerobic fermentation method using the device described in Embodiment 1, including:

[0037] (1) The fermented raw materials such as livestock and poultry manure, which have been mixed and diluted in the raw material premixing tank 1, are transported to the anaerobic fermentation tank 3 through the pump 2, under the conditions of a medium temperature of 35°C-40°C and a hydraulic retention time of 20-25d Anaerobic fermentation;

[0038] The continuous stirring reactor system is adopted in the anaerobic fermentation tank, so that the fermentation raw materials are fully fermented, and the materials are respectively fed in and out every day;

[0039] After opening the feed valve 6, the biogas slurry produced by the fermenter is transported to the biogas slurry stripping system under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com