Powder injection lance and method of refining molten iron using the powder injection lance

A technology for molten iron and spray guns, which is applied to the improvement of process efficiency, furnaces, manufacturing converters, etc., can solve problems such as increased manufacturing costs, prolonged refining time, and inability to blow powder, and achieve the effect of improving heating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1)

[0095] Hereinafter, the present invention will be described in more detail with reference to the drawings.

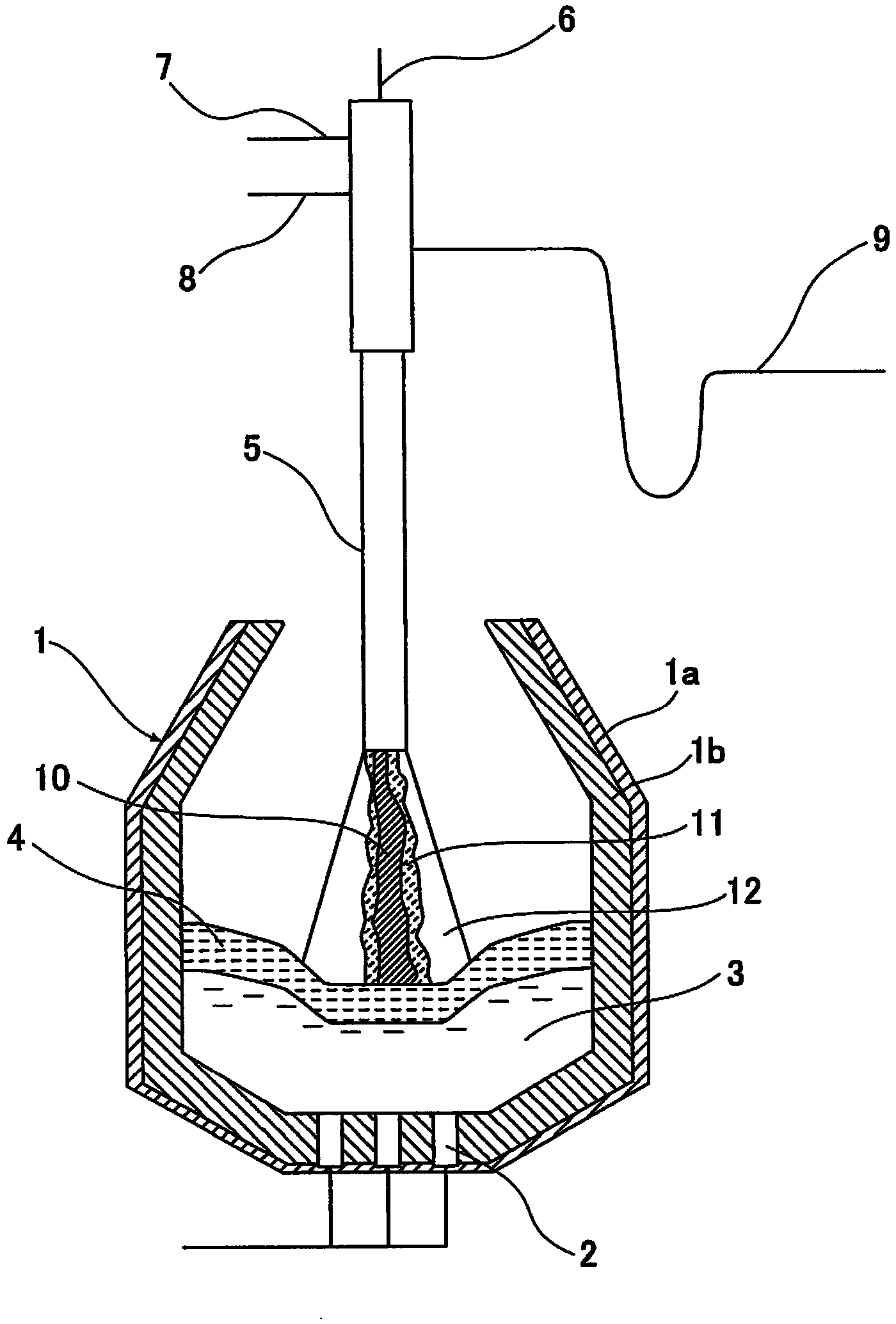

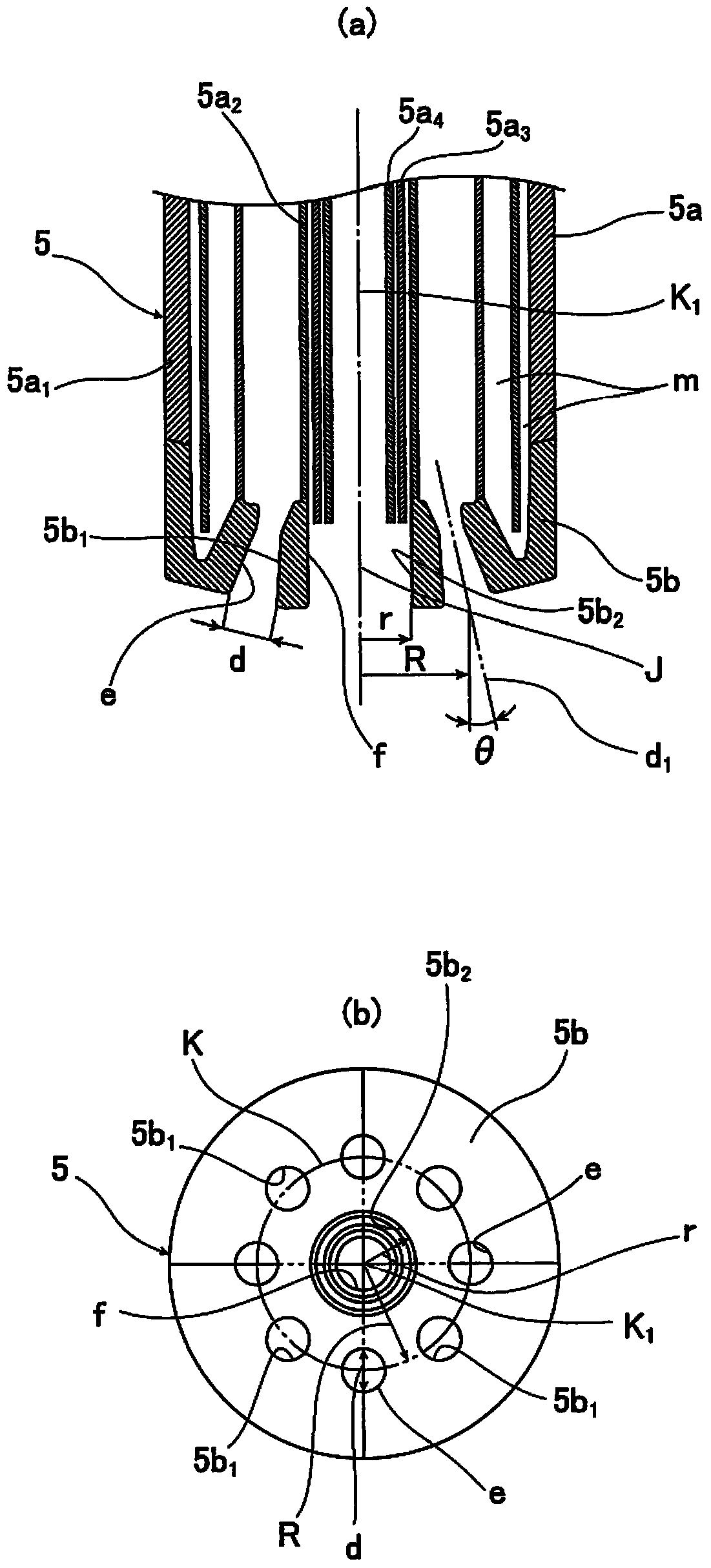

[0096] figure 1 It is a figure which shows the state which installed the powder injection lance based on this invention in the converter type refinery facility, figure 2 (a), figure 2 (b) is an enlarged view showing the cross section of the front end portion of the powder injection gun according to the present invention. Furthermore, in Embodiment 1 of the present invention, the reaction container includes, for example, an iron bath type refining furnace.

[0097] Reference numeral 1 in the figure denotes a furnace body. The furnace body 1 is configured to include an iron shell 1a forming the skeleton of the furnace body 1, and a refractory layer 1b applied inside the iron shell 1a.

[0098] In addition, reference numeral 2 denotes a bottom tuyere, which is installed at the bottom of the furnace body 1, and is used to blow in an inert gas such as Ar gas to stir th...

Embodiment 1

[0124] As a top-blown lance, use the above-mentioned figure 2 For the spray gun with the structure shown, the liquid iron with the composition shown in Table 2 is filled together with iron scrap into the above-mentioned 2.5t capacity figure 1 The combined top-bottom blowing converter shown in Table 3 carried out dephosphorization blowing under the conditions.

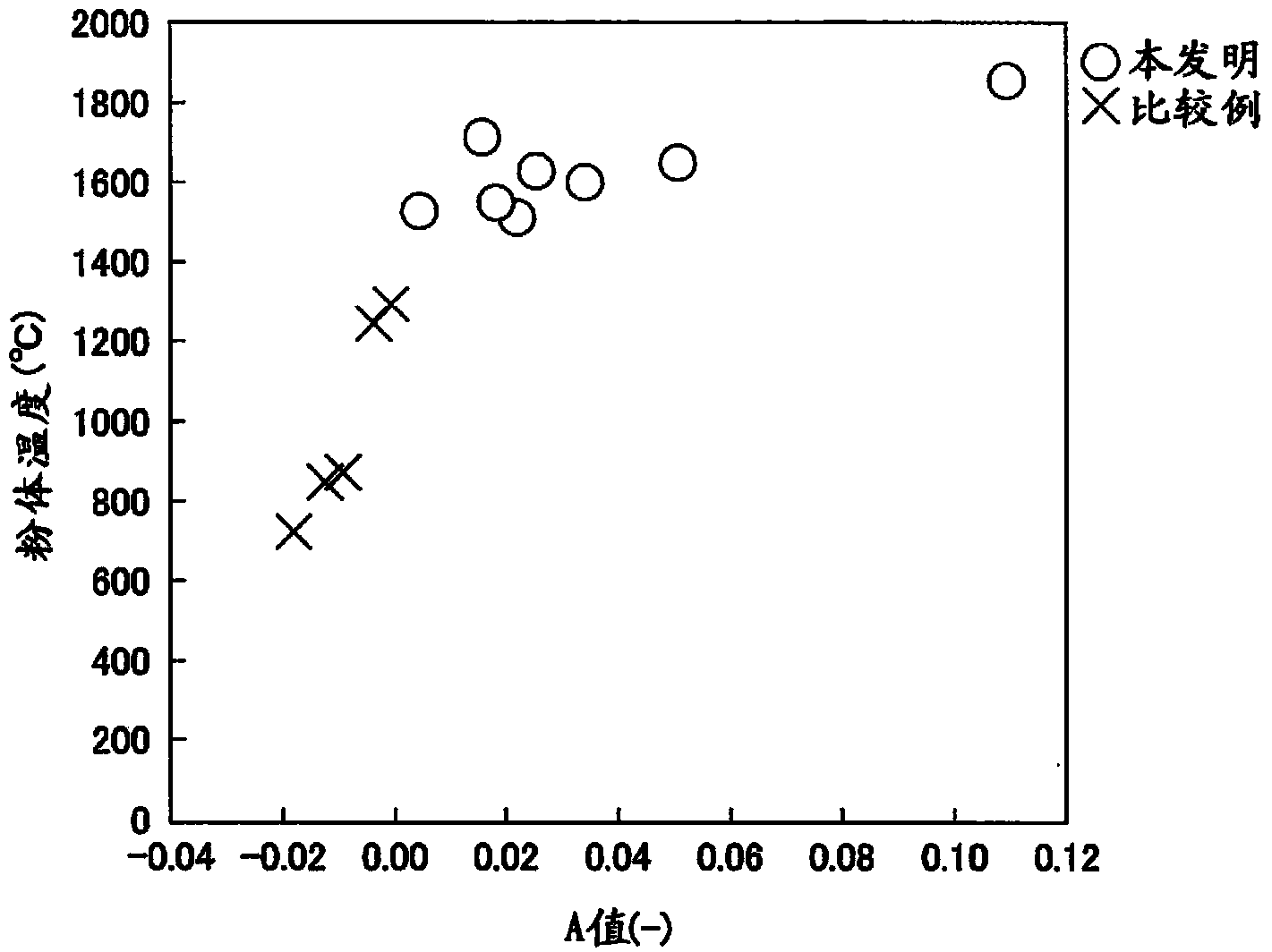

[0125] And thereafter, liquid discharge and slagging are carried out, and then the molten iron after the dephosphorization treatment is filled into the same top-bottom re-blowing converter together with the iron scrap, and decarburization blowing is carried out under the conditions of Table 3, thereby targeting at The effect of the A value of the top blowing lance on the mixing ratio of molten iron was investigated. Table 4 shows the results thereof.

[0126] In addition, during the dephosphorization blowing process, after filling the furnace with iron scrap, it is filled with molten iron at a temperature of 1350°C, ...

Embodiment approach 2)

[0146] Embodiment 2 of the present invention is directed to an oxidation refining process in which an oxidizing gas for refining is supplied from a top blowing lance to molten iron accommodated in a converter. As the oxidation refining treatment, preliminary dephosphorization treatment of molten iron and decarburization refining treatment of molten iron are currently performed, and the present invention can be applied to any of the oxidation refining treatment. When the present invention is applied to decarburization and refining of molten iron, the present invention can be implemented on molten iron after preliminary dephosphorization treatment, or can be implemented on molten iron that has not been subjected to preliminary dephosphorization treatment. The present invention can also be applied when the present invention is applied to the preliminary dephosphorization treatment and the molten iron refined by the preliminary dephosphorization treatment is decarburized and refine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com