Method for using metallurgical fume for coal gasification

A technology of coal gasification and flue gas, which is applied in the manufacture of combustible gas, petroleum industry, joint combustion mitigation, etc., can solve the problem of poor utilization of heat, achieve resource utilization, reduce carbon emissions, and improve utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

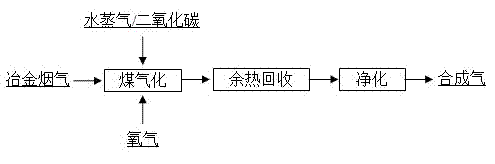

[0019] Embodiment 1: the specific preparation steps of this embodiment are: as figure 1 As shown, the metallurgical flue gas with a temperature of 800 °C is mixed with water vapor, and then the above mixed gas is passed into high-quality anthracite particles for coal gasification reaction, and finally the tail gas obtained after the coal gasification reaction is subjected to waste heat recovery and purification treatment, and finally Get purified CO, H 2 . The reaction conditions and reaction results are shown in Table 1 and Table 2. The coal powder used is 100g of high-quality anthracite, the particle size is 20-40 mesh, the water vapor flow rate: 1 g / min, the oxygen flow rate: 0 Nm 3 / h.

[0020] Table 1 Simulated flue gas flow rate, temperature and composition

[0021]

[0022] Table 2 Flow rate, temperature and composition of tail gas after reaction

[0023]

Embodiment 2

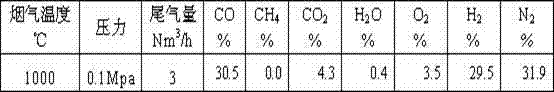

[0024] Embodiment 2: the specific preparation steps of this embodiment are: as figure 1 As shown, metallurgical flue gas and water vapor at a temperature of 1000°C are fed into coal for coal gasification reaction, and finally the tail gas obtained after coal gasification reaction is subjected to waste heat recovery and purification treatment, and finally the purified CO, H 2 . The reaction conditions and reaction results are shown in Table 3 and Table 4. The coal powder used is 100g of high-quality anthracite, the particle size is 20-40 mesh, the water vapor flow rate: 1 g / min, the oxygen flow rate: 0 Nm 3 / h.

[0025] Table 3 Simulated flue gas flow rate, temperature and composition

[0026]

[0027] Table 4 Flow rate, temperature and composition of tail gas after reaction

[0028]

Embodiment 3

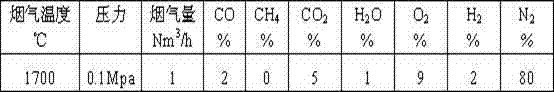

[0029] Embodiment 3: the specific preparation steps of this embodiment are: as figure 1 As shown, metallurgical flue gas and water vapor at a temperature of 600°C are used to assist the introduction of oxygen, and then the above-mentioned mixed gas is introduced into the coal for coal gasification reaction, and finally the tail gas obtained after the coal gasification reaction is subjected to waste heat recovery and purification treatment , and finally the purified CO, H 2 . The reaction conditions and reaction results are shown in Table 5 and Table 6. The coal powder used is 100g of high-quality anthracite, the particle size is 20-40 mesh, the water vapor flow rate: 1 g / min, the oxygen flow rate: 5 Nm 3 / h.

[0030] Table 5 Simulated flue gas flow rate, temperature and composition

[0031]

[0032] Table 6 Flow rate, temperature and composition of tail gas after reaction

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com