Multi-stage heat tube enhanced heat exchange ship exhaust gas waste heat temperature-difference power generation device and method

A technology of thermoelectric power generation and enhanced heat transfer, which is applied in the direction of generators/motors, electrical components, etc., and can solve the problems of excessive thermal resistance coefficient at the cold and hot ends of power generation devices, low output power of thermoelectric power generation, and low utilization rate of flue gas waste heat, etc. , to achieve the effects of ship energy efficiency, overall performance improvement, and thermal efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

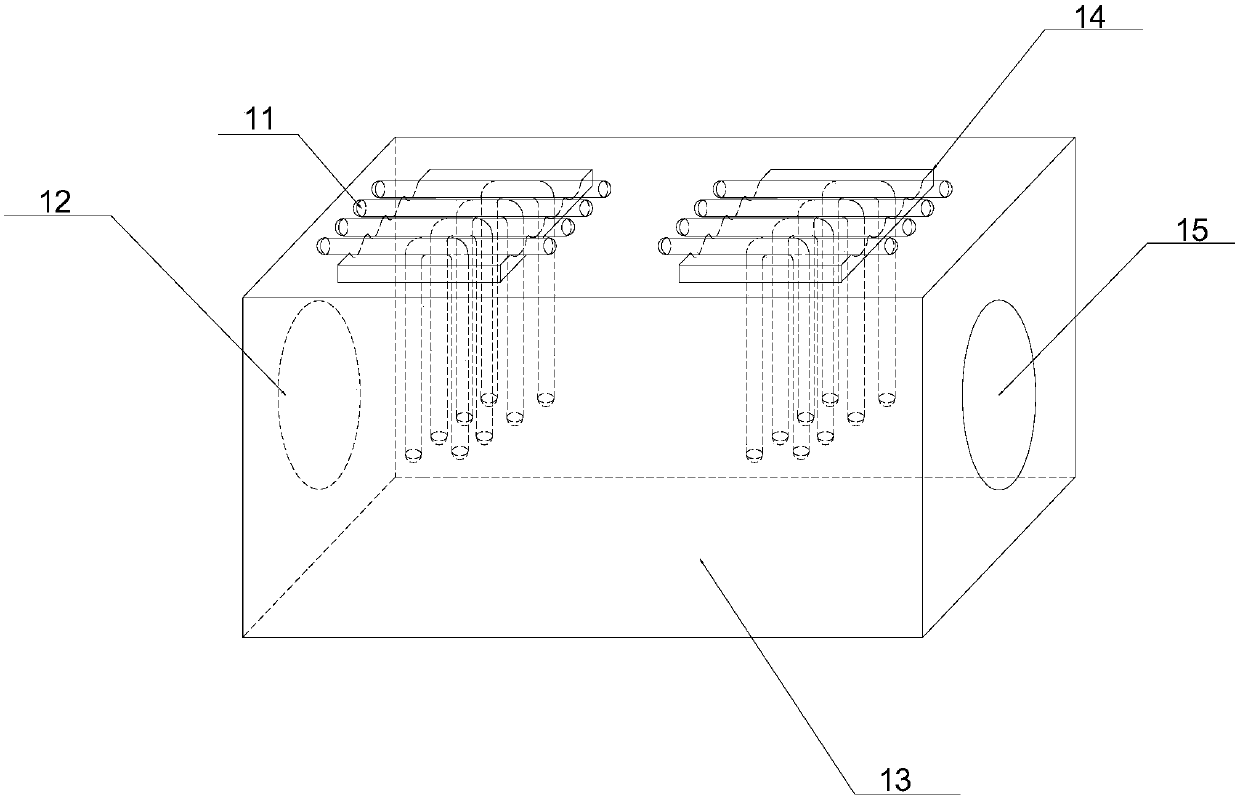

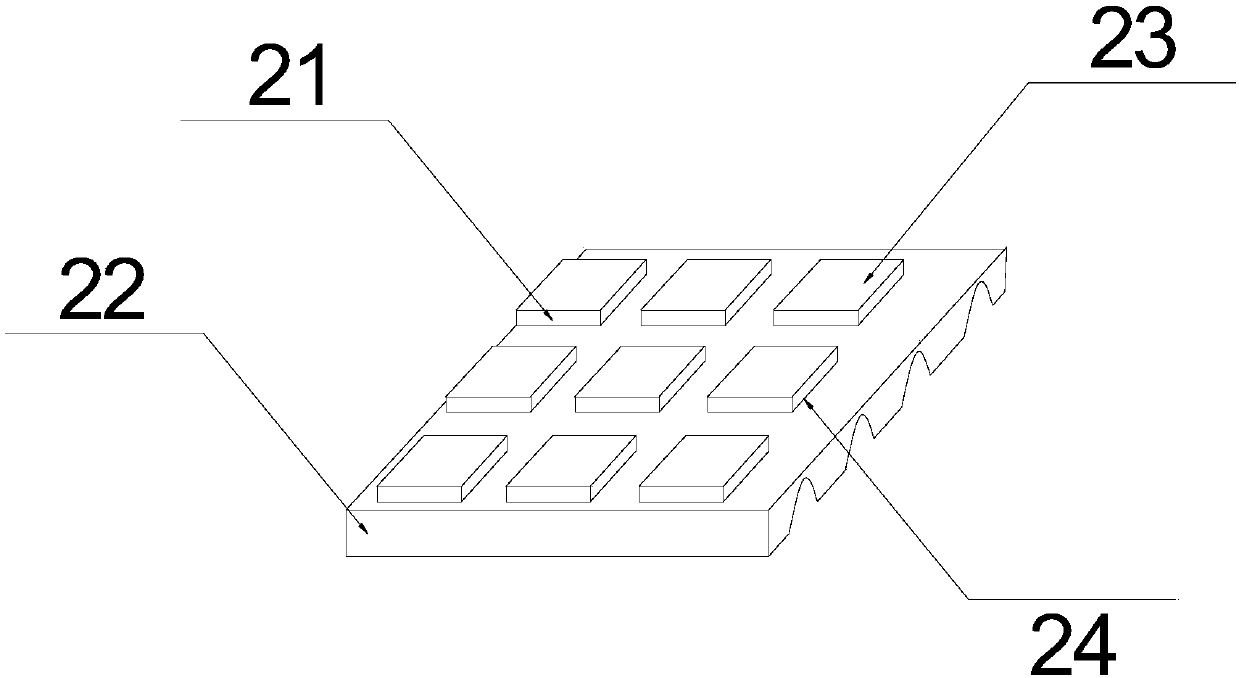

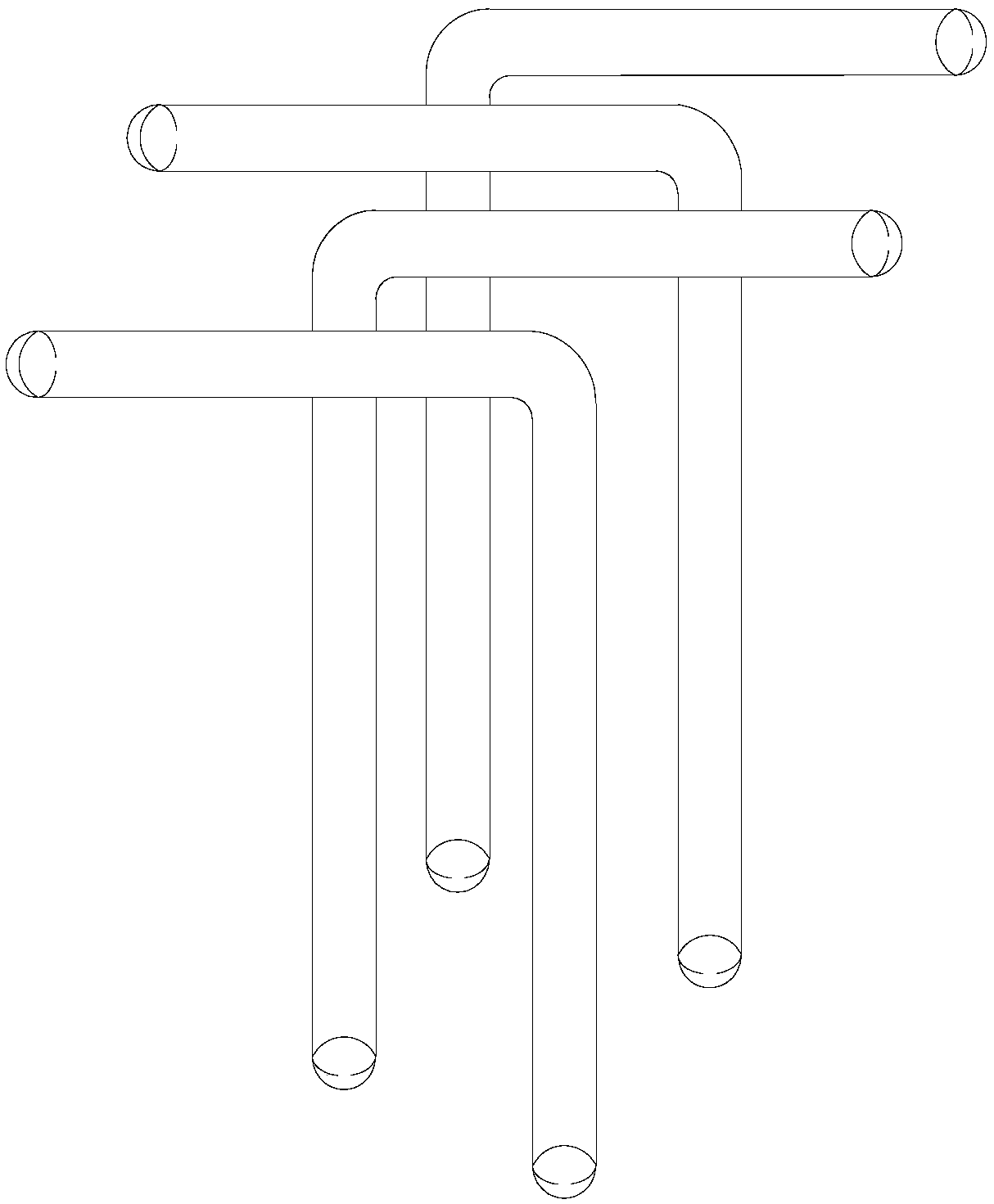

[0051] Such as Figure 1 to Figure 8 As shown, a ship waste gas waste heat thermoelectric power generation device with multi-stage heat pipes for enhanced heat exchange includes: a device body structure 13, a rear copper plate 61, a front copper plate 62, a top copper plate 63, a thermoelectric power generation sheet 21, and a hot end heat pipe 11 , cold end heat pipe 73, cold end copper plate and cooling copper plate; in order to achieve optimal heat transfer efficiency and reduce heat loss, copper is selected as the overall material of the device after comprehensive consideration.

[0052]The device body structure 13 has a smoke inlet 12 at the front end and a smoke gas outlet 15 at the end; a top copper plate 63 is installed on the top of the device body structure 13, and a front copper plate 62 and a rear copper plate 61 are respectively installed on the front and rear sides. ; The top copper plate 63, the front side copper plate 62 and the rear side copper plate 61 are th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com