Energy-saving gas stove

A gas stove, energy-saving technology, applied in the field of gas stoves, can solve the problems of increasing the heat of the pot, the heat cannot be stored, and needs to be improved, and achieve the effects of enhanced heat transfer, high phase transition temperature, and improved gas utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the present invention, the present invention will be specifically introduced below in conjunction with the accompanying drawings. It should be noted that the protection scope of the present invention is not limited to the scope described in the embodiments.

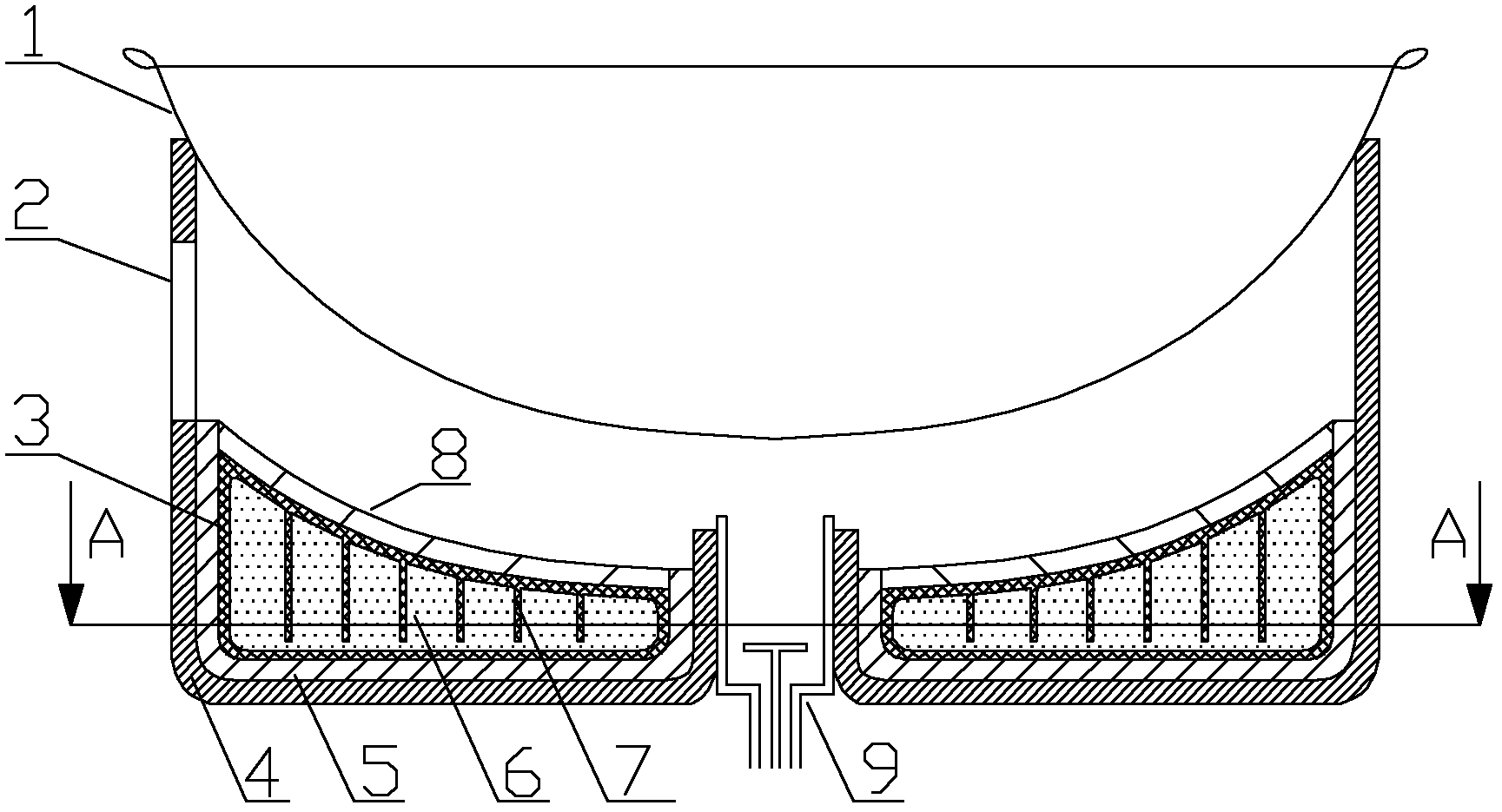

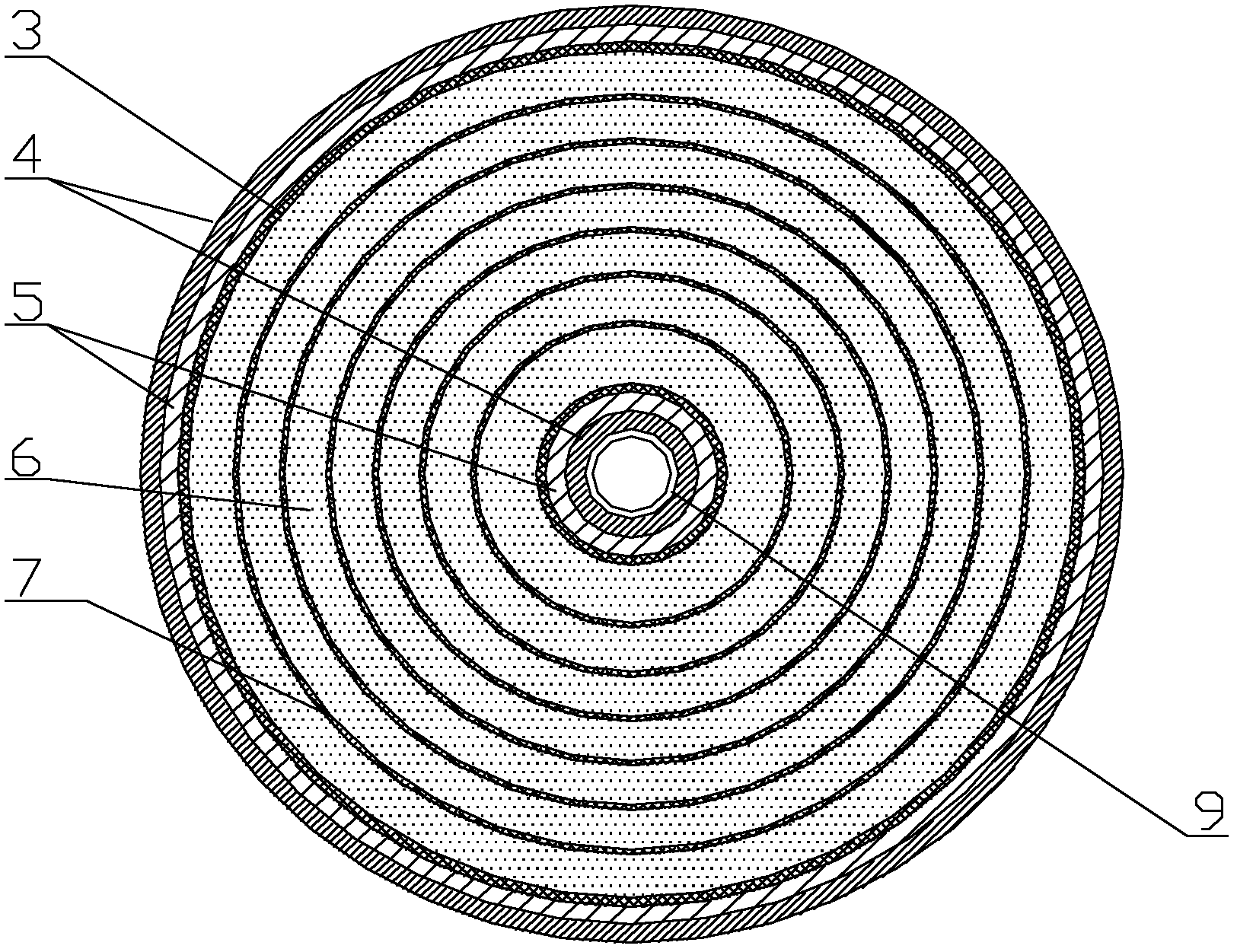

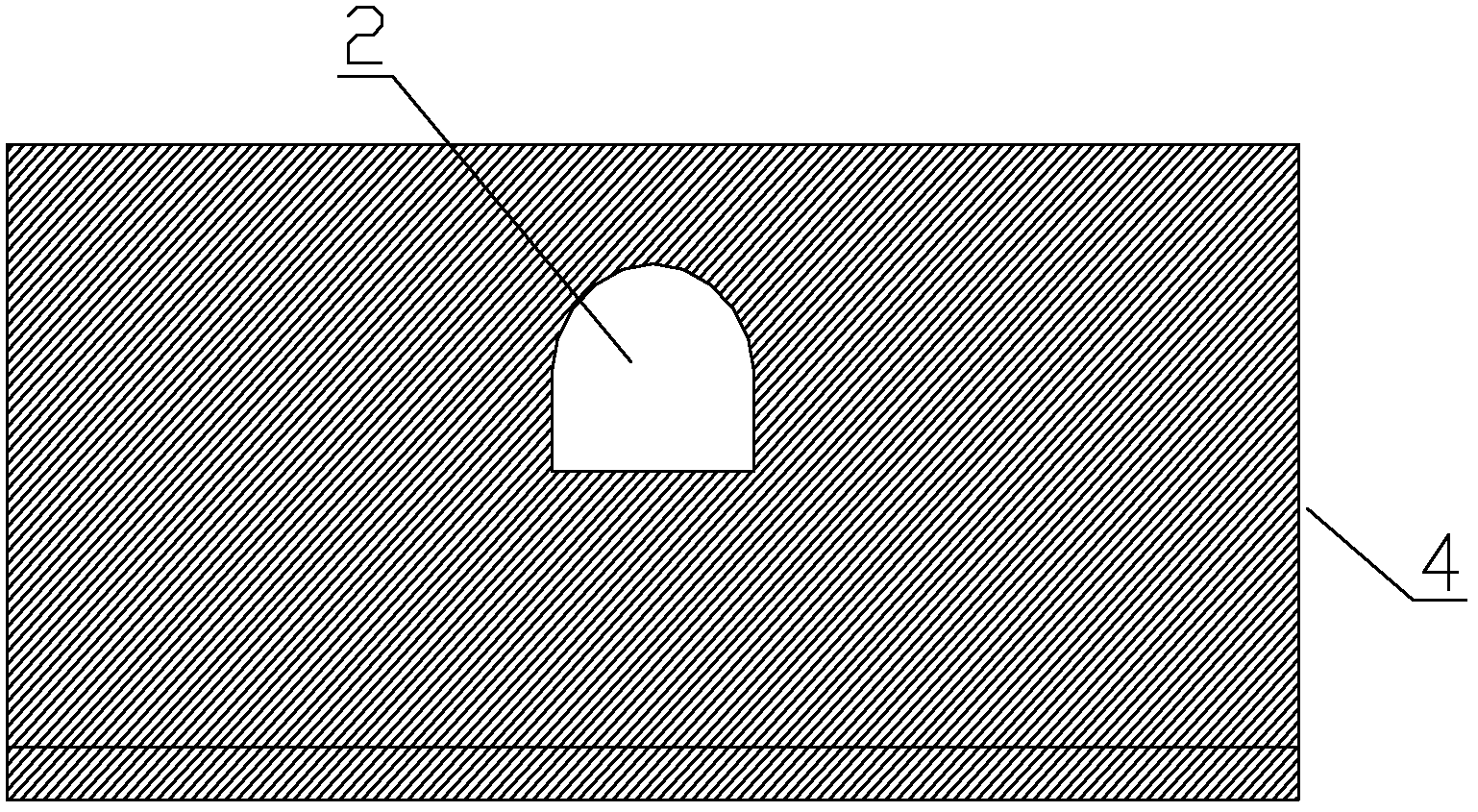

[0028] Such as Figure 1-3 As shown, an energy-saving gas stove includes an energy-gathering cavity 3, a furnace wall 4, a heat insulating material 5, a phase change heat storage body 6, ribs 7, an infrared radiation ceramic plate 8 and a gas burner 9; the furnace wall 4 In order to open the cavity structure, the upper end of the opening is used to place pots, and the central opening at the bottom of the furnace wall 4 is provided with a gas burner 9; the inner and lower ends of the furnace wall 4 are provided with an energy-gathering chamber 3, which is a cylindrical cavity structure, the upper surface of the energy-gathering chamber 3 is a hemispherical curved surface, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com