Device and method for waste heat recovery of high-temperature molten slag by means of two-step method

A waste heat recovery device and high-temperature melting technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of insufficient recovery and utilization of thermal energy of high-temperature molten slag, deteriorating labor conditions on production sites, and no recovery of high-temperature thermal energy, etc., to save layout space, improving working conditions, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

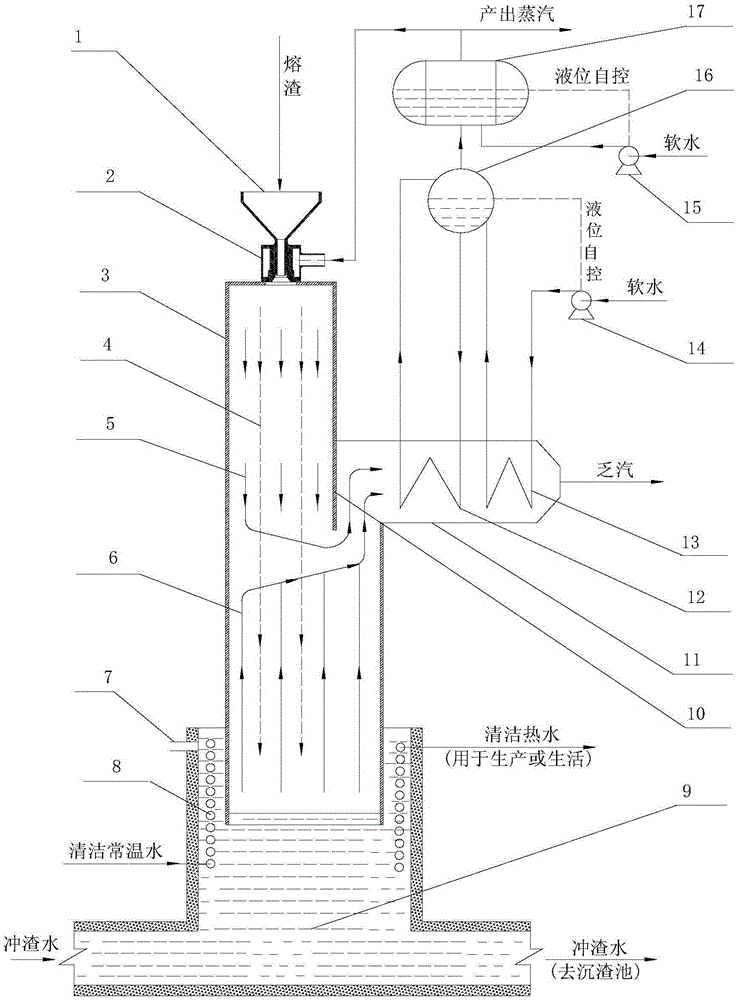

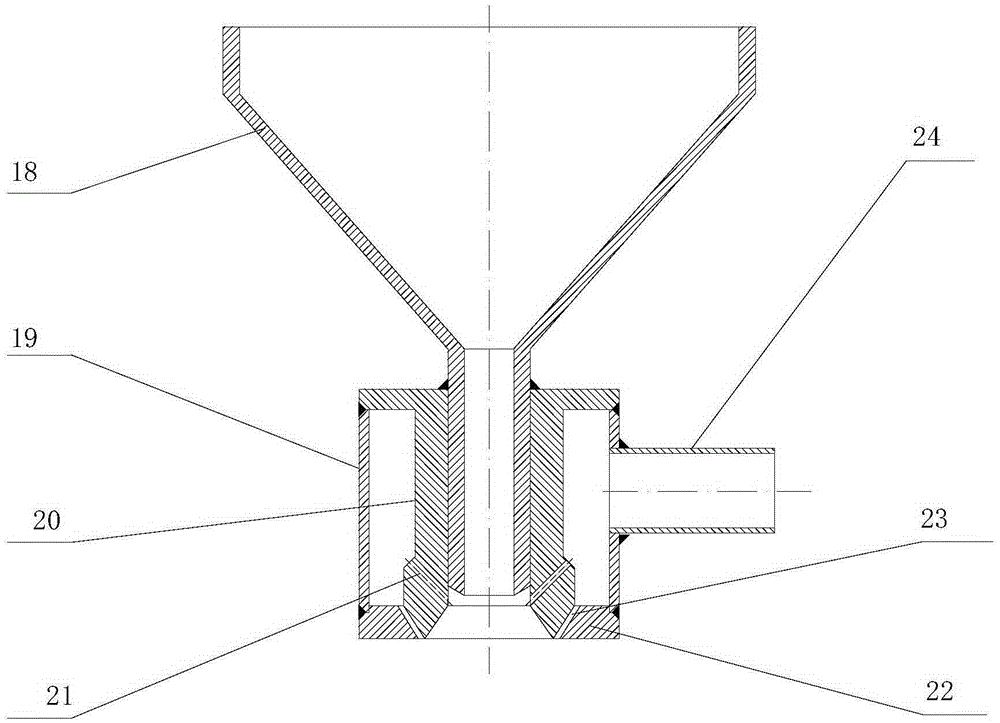

[0031] like figure 1 As shown, the high-temperature molten slag waste heat recovery device provided by the present invention includes a jet granulator 2, a granulation cylinder 3, a water slag pool 9, a spiral tube heat exchanger 8, a heat exchanger flue 11, and a steam drum 16 , Regenerator 17 and so on. The granulation cylinder 3 can be a circular cylinder or a square cylinder. The lower end of the granulation cylinder 3 is inserted into the water slag pool 9. The insertion requirement is that there is a pressure difference between the inside and outside of the lower end of the granulation cylinder. To form a liquid level difference, the height from the water level in the slag pool 9 to the lower end surface of the granulation cylinder 3 is greater than the height of the water level drop in the granulation cylinder 3 due to positive pressure, ensuring that the lower end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com