Device for preparing hydrogen-rich gas by gasifying biomass under catalysis of high-temperature metallurgical slag particles and method

A catalytic gasification and metallurgical slag technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve problems such as low quality, poor recovery efficiency of waste heat in slag process, easy carbon deposition and deactivation of catalysts, etc., and achieve hydrogen content High, avoiding secondary energy consumption, avoiding the effect of surface area carbon deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

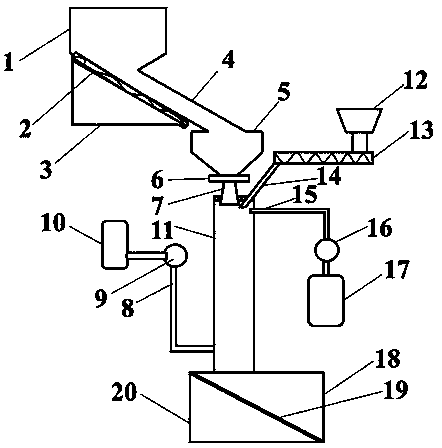

[0034] Example 1: see figure 1 , a device for producing hydrogen-rich gas by catalytic gasification of biomass with high-temperature metallurgical slag particles, including a slag rotary granulation device 1, a high-temperature slag particle storage room 5, a downcomer reactor 11, a steam generator 10, and a screw feeder for biomass raw materials device 13, separator and hydrogen-rich gas collector 17.

[0035]The high-temperature slag storage chamber 5 and the biomass raw material screw feeder 13 are respectively located above the downcomer reactor 11, the separator is located under the downcomer reactor 11, and the steam generator 10 and the hydrogen-rich gas collector 17 are respectively located in the downcomer reactor. Both sides of the tube reactor 11; the slag rotary granulation device 1 is provided with a granulated slag sieve 2, and the granulated slag sieve 2 divides the molten slag rotary granulation device 1 into two parts, which are located in the granulated sla...

Embodiment 2

[0040] Example 2: The method for producing hydrogen-rich gas by catalytic gasification of biomass with high-temperature metallurgical slag particles adopts the device for producing hydrogen-rich gas by catalytic gasification of biomass with high-temperature metallurgical slag particles as described in Example 1. The specific steps are as follows:

[0041] 1) Fully pretreat the biomass raw material, including drying and crushing, so that the moisture content of the biomass raw material is lower than 10%, and the particle size of the biomass particle is less than 1mm, and then put the biomass raw material into the biomass raw material storage room 12.

[0042] 2) After being processed by the slag rotary granulation device 1, the high-temperature metallurgical slag particles with a particle size between 2 and 7mm enter the high-temperature slag particle storage room 5, which facilitates the separation of biomass residual carbon and high-temperature metallurgical slag particles, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com