Hot conflux main pipe residual heat reclamation and utilization system using gas medium as hot source

A waste heat recovery and parent control technology, applied in heating systems, applications, waste heat treatment, etc., can solve the problems of difficult to achieve waste heat recovery, low waste heat recovery rate, and heavy maintenance workload, and achieve easy operation and maintenance. Simple system operation , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

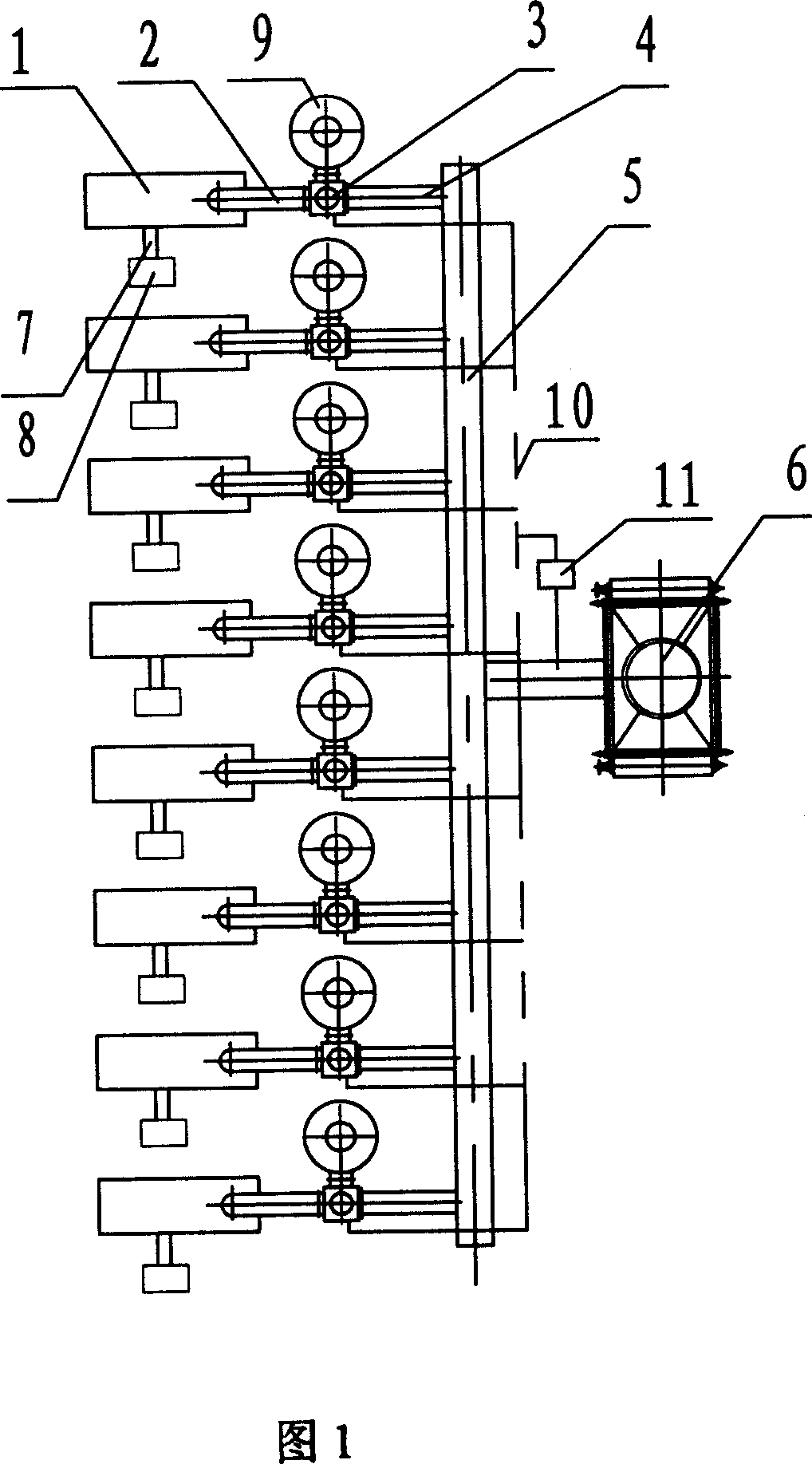

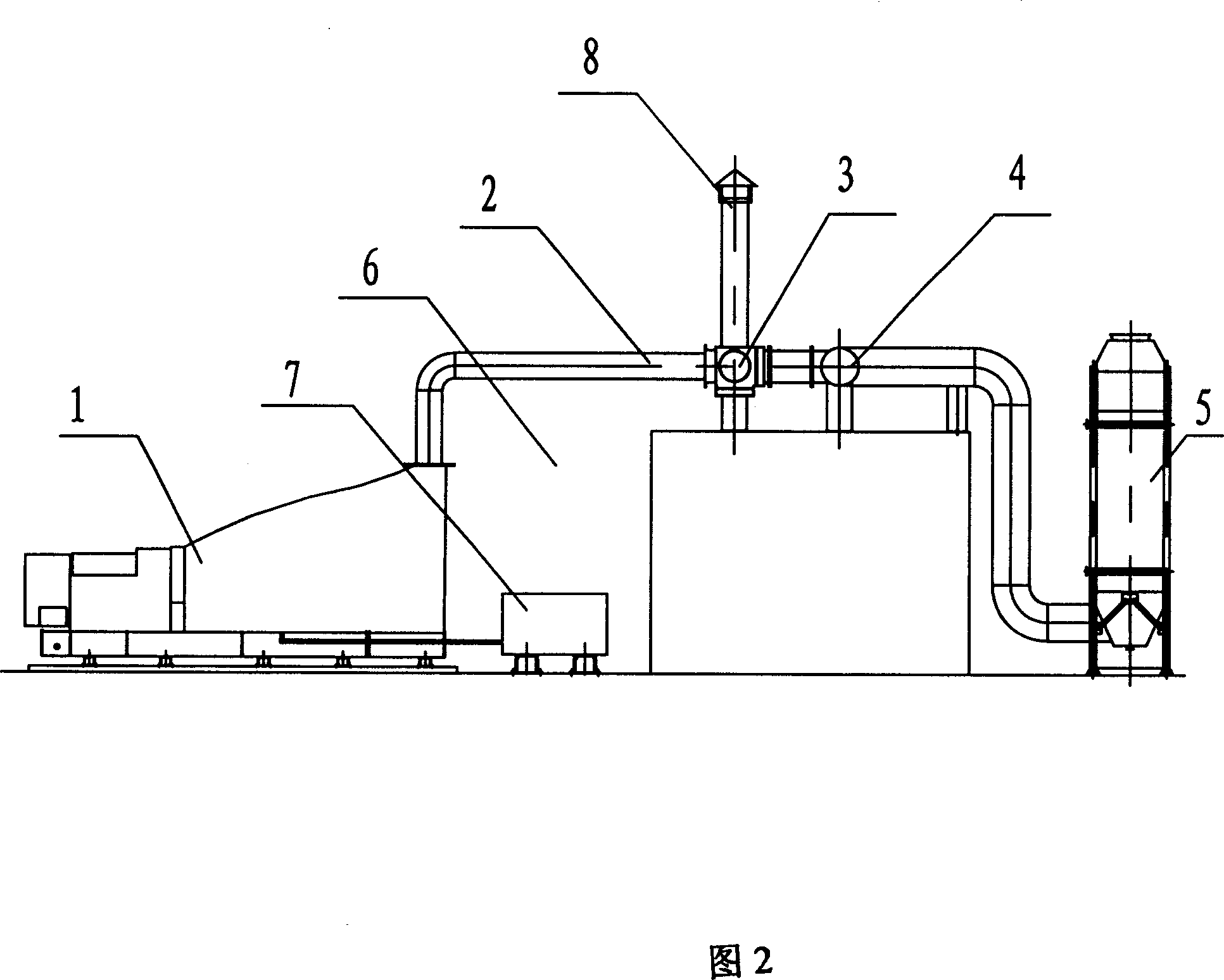

[0015] Take 8 diesel generators with a capacity of 1000kW as heat source 1 as an example:

[0016] 8 diesel generators 1 with a capacity of 1000kW, and the capacity of the exhaust heat source is 232.4M 3 / min, and the temperature of the hot air source is 449°C. In the planning and construction of the plant, the hot air source discharged from the generator is directly connected to the atmosphere, and the site where the waste heat recovery device is installed is not considered. Outside the generator building is the road in the factory area. There is an open space at one end of the generator building. Now the heat from 8 diesel generators 1 with a capacity of 1000kW is recovered into a waste heat recovery device.

[0017] As shown in Figures 1 and 2, it is a schematic diagram of the waste heat recovery and utilization system of the heat confluence main pipe with the heat source as the gas medium. The exhaust hot gas sources of the eight generators are respectively passed through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com