Method and system suitable for recovering waste heat of blast furnace slag flushing water

A blast furnace slag flushing water and waste heat recovery technology, applied in recycling technology, furnace, waste heat treatment, etc., can solve the problems of fouling on the surface of the heat absorber, poor heat transfer effect, slow surface water flow, etc., to improve slag flushing Water waste heat recovery rate, high thermal efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

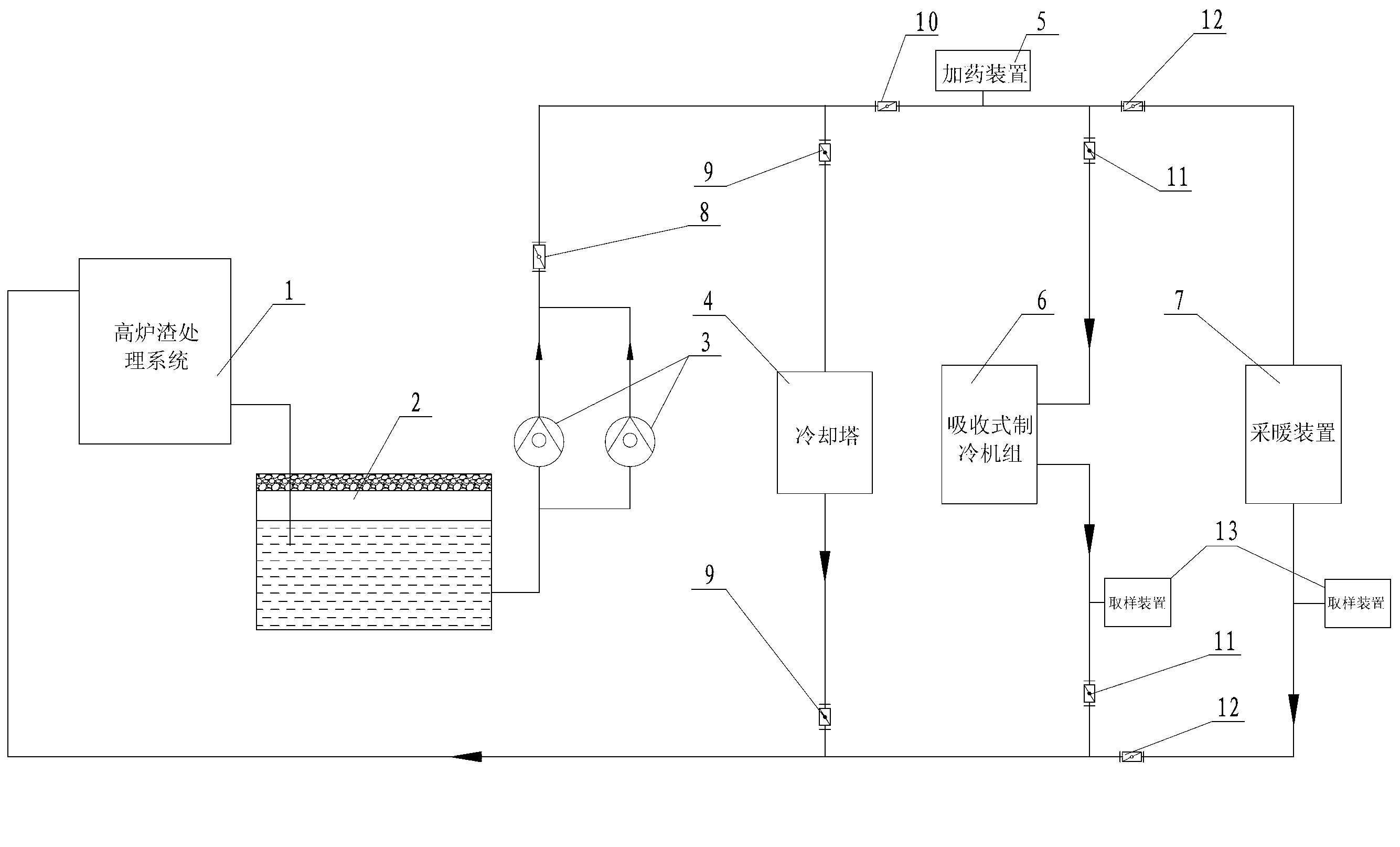

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0033] A method of the present invention applicable to waste heat recovery of blast furnace slag flushing water comprises the following steps:

[0034] S1, filter the high-temperature blast furnace slag washing water and store it in the hot water pool;

[0035] S2, pressurized delivery of hot water, hot water can be delivered through a circulating pump;

[0036] S3, sending hot water into absorption refrigeration unit or heating device or cooling tower;

[0037] When the hot water is sent to the absorption refrigeration unit, the absorption refrigeration unit is driven by the hot water to perform refrigeration;

[0038] When the hot water is sent to the heating device, the hot water exchanges heat with the room and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com