System for deeply recovering smoke waste heat through absorbing type heat pump and two-stage heat exchanger

An absorption heat pump and waste heat recovery technology, applied in heat recovery systems, direct contact heat exchangers, heat exchangers, etc., can solve the problems of underutilization of sensible heat and latent heat, and achieve high waste heat recovery rate and system Low energy consumption, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below with reference to the drawings and technical solutions.

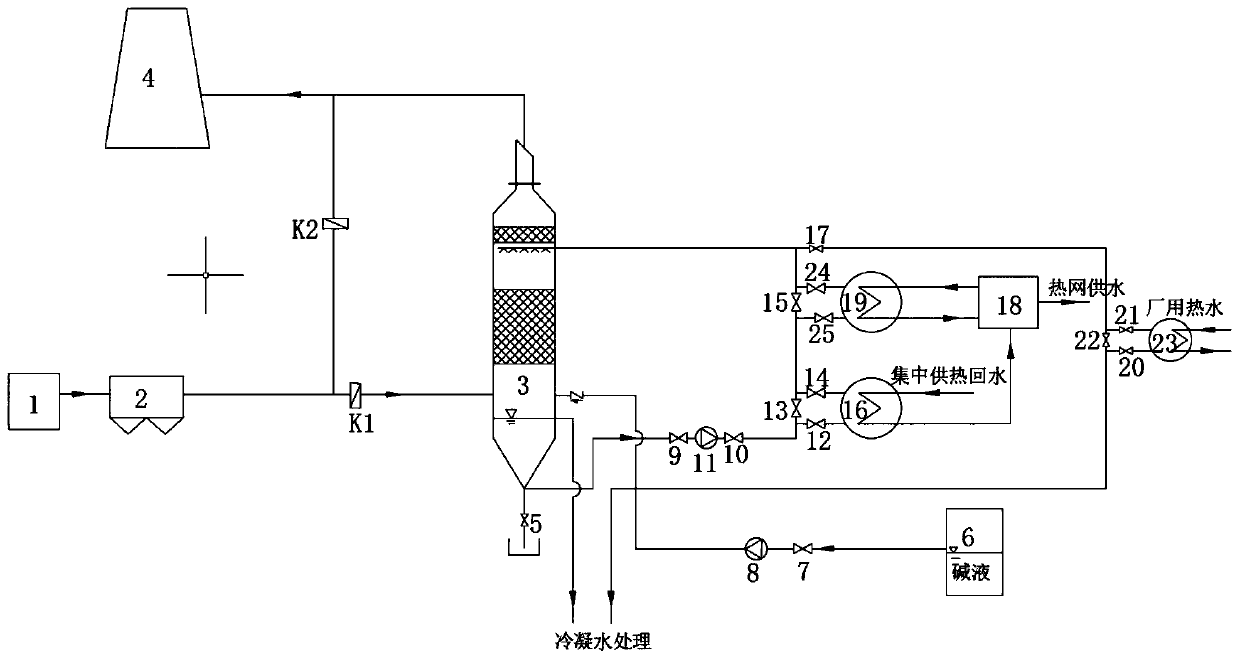

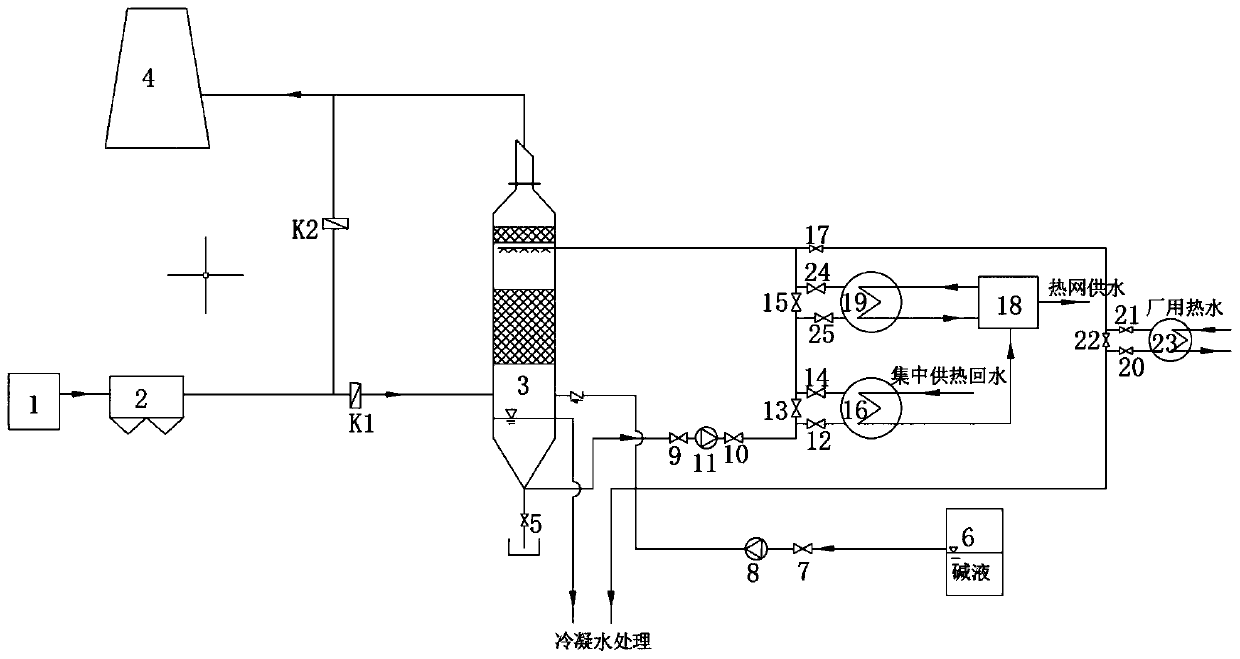

[0022] figure 1 In the system, a flue gas waste heat deep recovery system using an absorption heat pump and a two-stage heat exchanger includes a boiler 1, a dust collector 2, a waste heat recovery tower 3, a chimney 4, a NaOH solution tank 6, and a lye transfer pump 8. Waste heat recovery tower inlet valve K1, bypass pipe valve K2, waste heat recovery tower circulating water pump 11, plate heat exchanger 16, absorption heat pump 18, plate heat exchanger 19, and plate heat exchanger 23.

[0023] An axial fan is arranged at the flue gas outlet in the waste heat recovery tower 3 to overcome the airflow resistance in the tower and facilitate the discharge of flue gas. At the same time, a mist eliminator is installed between the axial flow fan and the slurry spray layer.

[0024] The waste heat recovery tower 3 is provided with an overflow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com