Substrate holder mounting device and substrate holder container chamber

a technology for mounting devices and substrates, which is applied in the manufacture of record carriers, coatings, electrical devices, etc., can solve the problems of difficult to reduce the size of the substrate holder container chamber, useless space at the outer periphery, etc., and achieve the effect of reducing the size of the chamber, simplifying the device configuration, and saving the space of the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Description of Substrate Processing Device Configuration

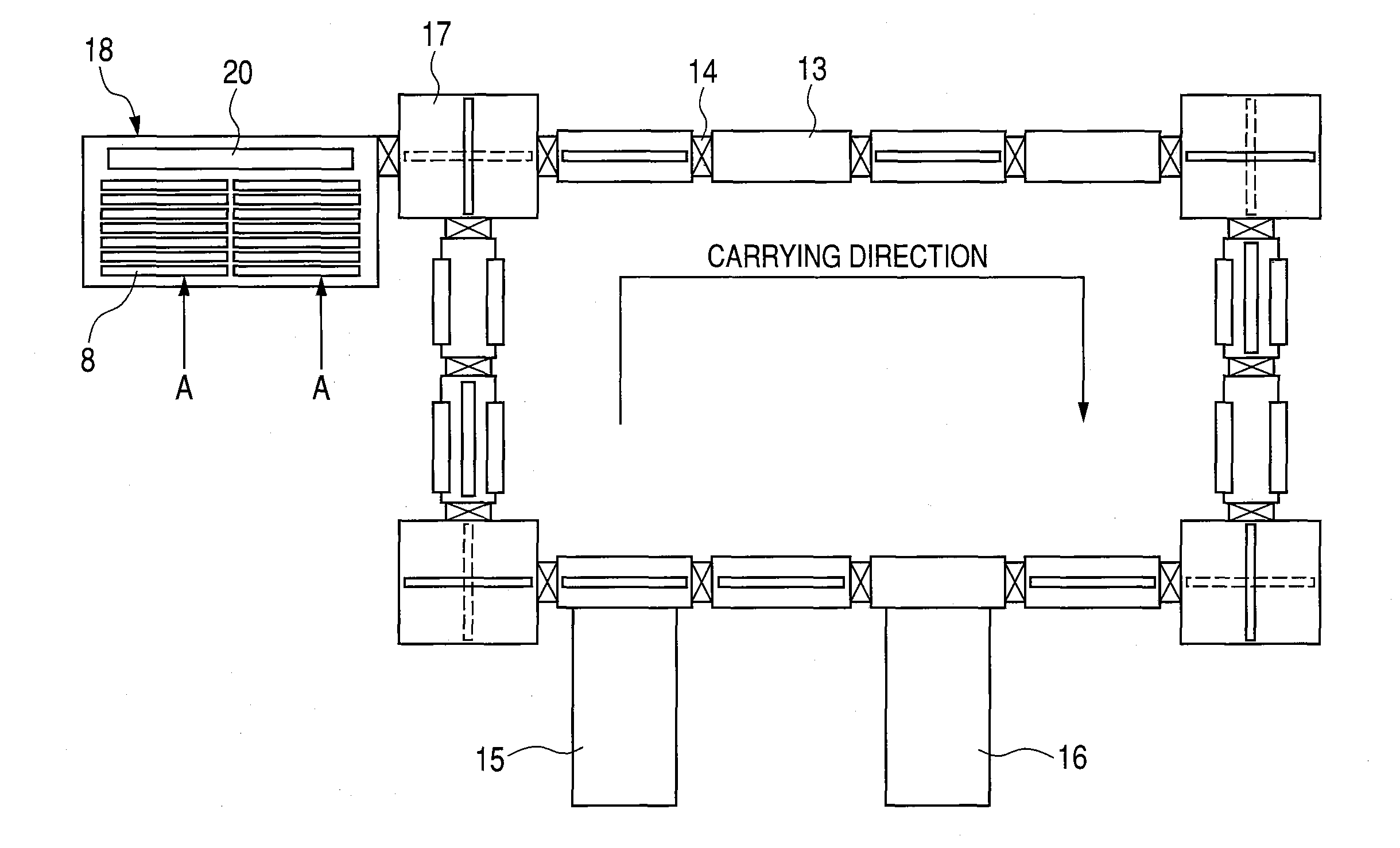

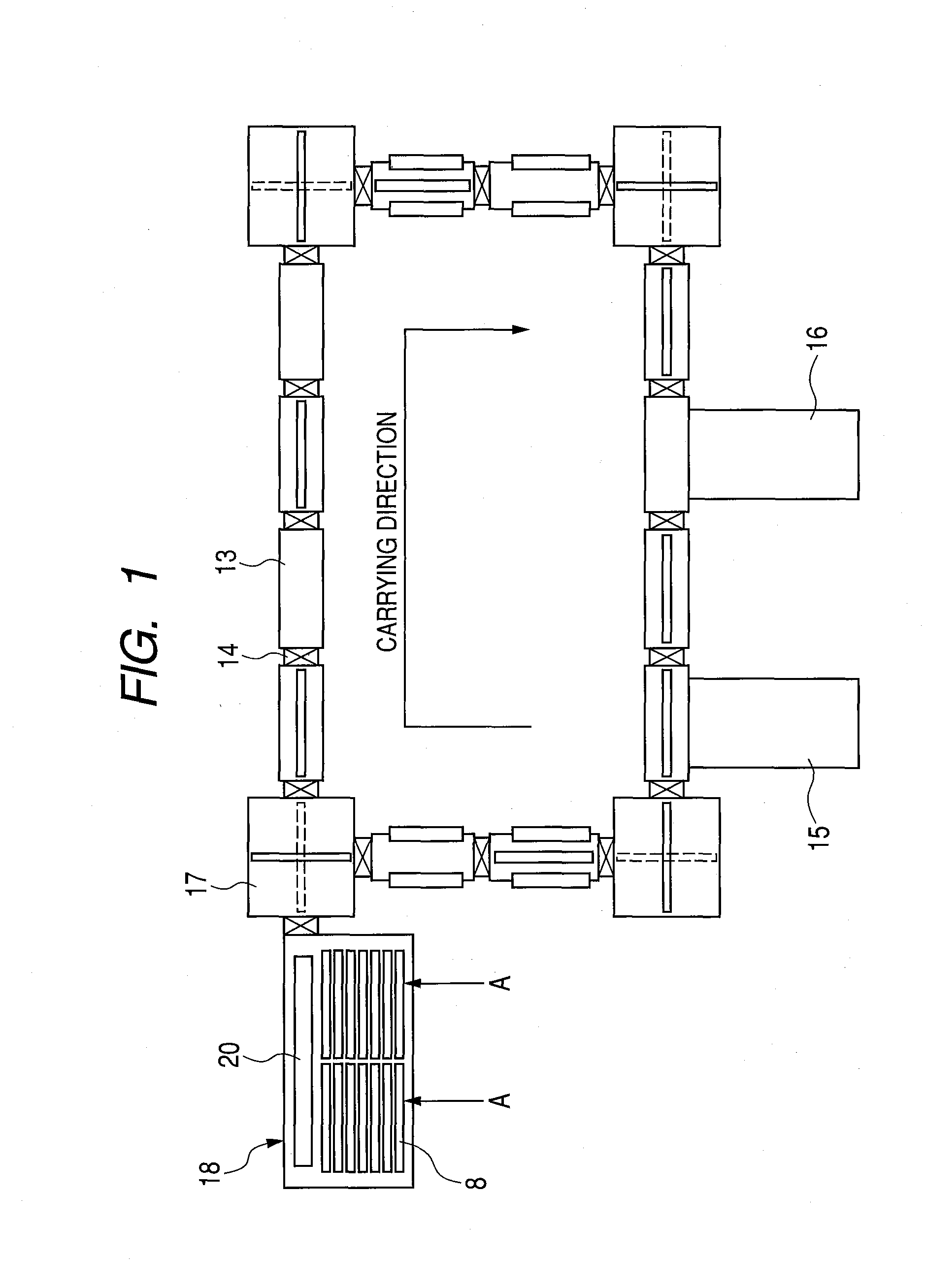

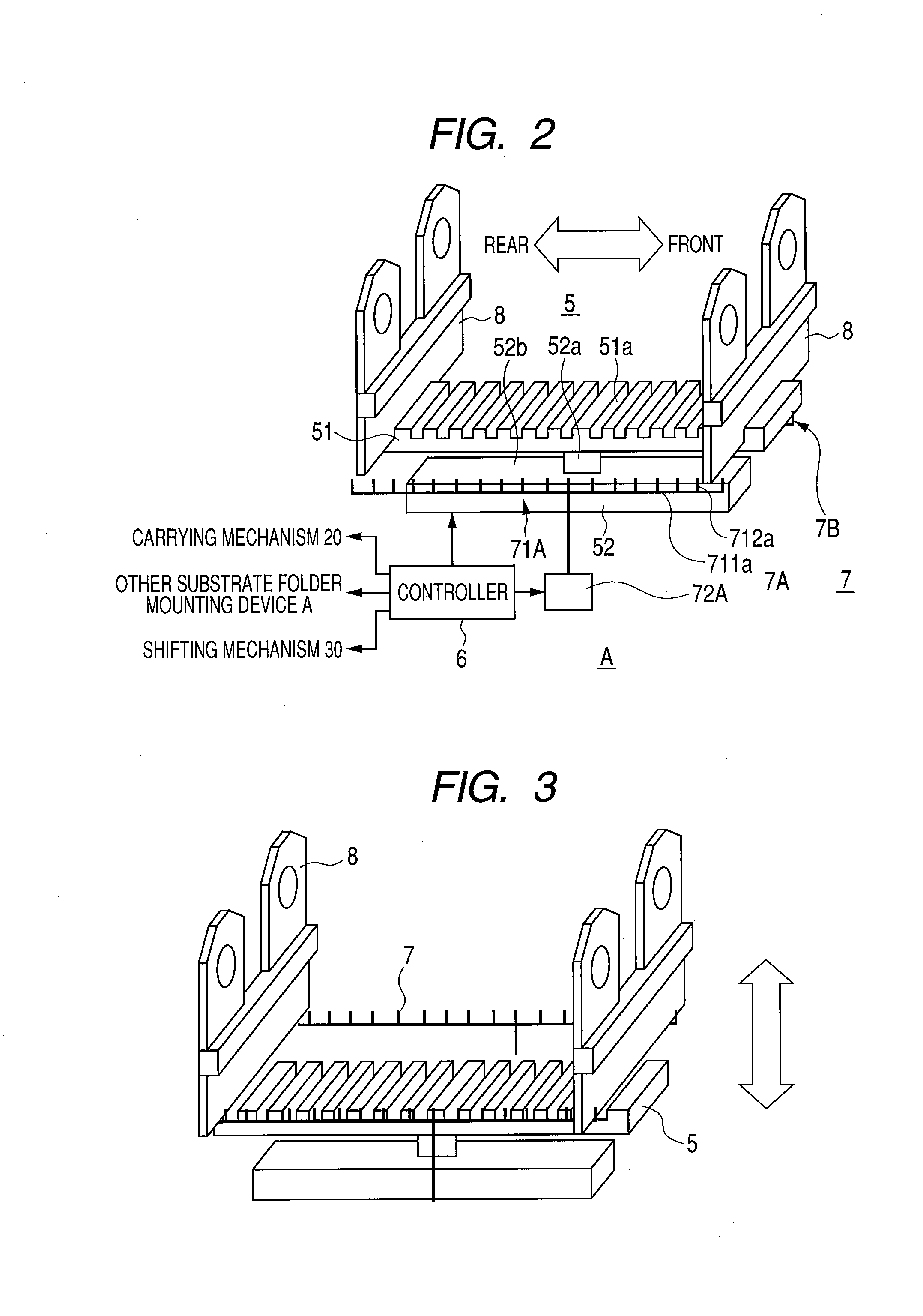

[0025]FIG. 1 is a plan view showing a schematic configuration of an in-line type substrate processing device according to the present embodiment. Such the in-line type substrate processing device is, for example, used as a device for manufacturing magnetic disks. In the substrate processing device of the present embodiment, a plurality of vacuum chambers 13 are arranged in a state of being connected to each other in an endless form (rectangular-shaped loop in FIG. 1). Each vacuum chamber 13 is a vacuum container in which gases are exhausted by an exclusive or nonexclusive exhaust system. A gate valve 14 is arranged at a boundary of each vacuum chamber 13, and the vacuum chambers 13 are connected to each other with an airtight state being kept therein. A substrate is held to be carried by a substrate holder 8 through a substrate processing device. A transport path is provided in the plurality of connected vacuum chambers 13, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic | aaaaa | aaaaa |

| angle of radiation | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com