Integrating injection moulding method

An injection molding, integrated technology, applied in injection molding, injection molding of plastic products, can solve the problems of large production space, low production efficiency, large clamping force of semi-finished products, etc., to achieve the effect of improving processing efficiency and saving equipment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned technical scheme of the present invention and its advantages clearer and easier to understand, the preferred solution is enumerated below and described in detail as follows:

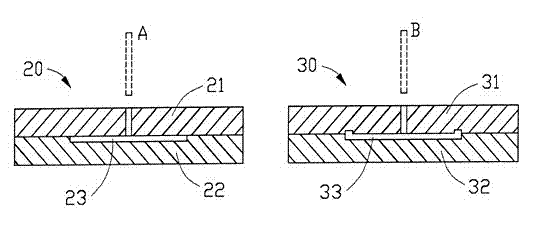

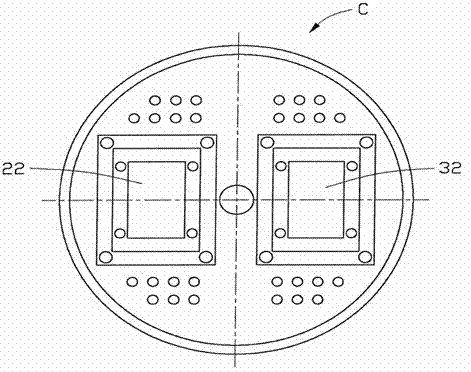

[0024] see attached image figure 1 A to Figure 3B As shown, the present invention provides an injection molding method, which can be applied to integral injection molding of two or more raw materials.

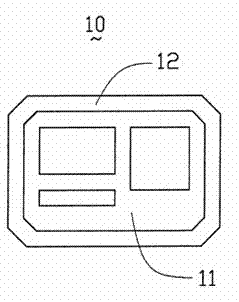

[0025] One of the embodiments of the present invention is to manufacture the notebook computer case 10, because the notebook computer case body 11 is a plastic material, and the sealing layer 12 formed on the notebook computer case body 11 is a rubber material, this just needs two different materials to be integrally injected Forming, the main manufacturing methods are as follows:

[0026] (1) First provide an injection molding machine equipped with two injection molding devices, namely, injection molding rubber tubes A and B, and a rotary table C, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com