Basin nectar bird feeder with improved stability

a feeder and basin bottle technology, applied in the field of bird feeders and bird feeders, can solve the problems of difficult cleaning, messy refilling of basin bottle feeders, and difficult cleaning of tubes, and achieve the effects of improving stability, improving stability, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

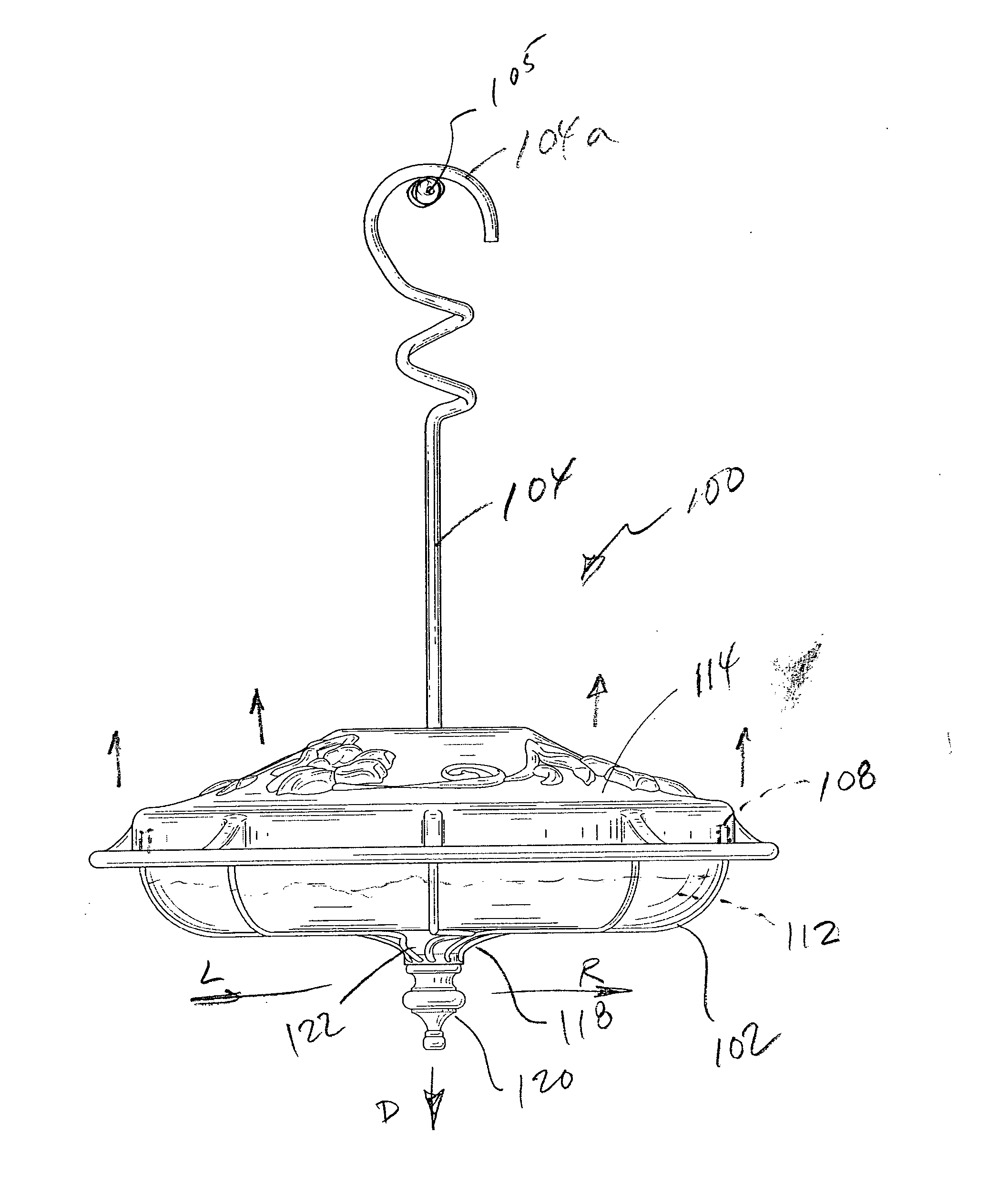

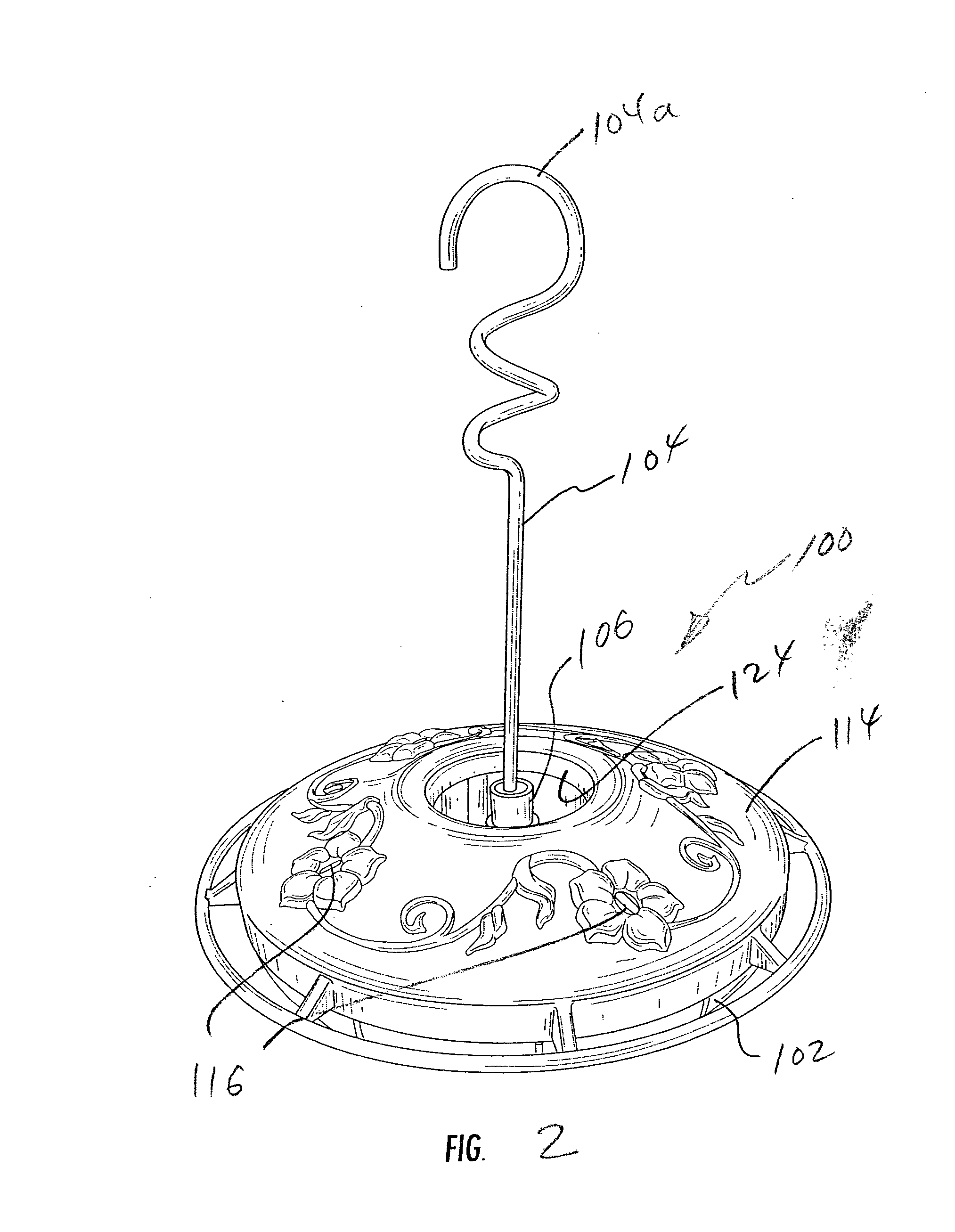

[0031] In FIGS. 2-6, the bird feeder 100 of the present invention is shown. The feeder 100 includes a base 102 with a hanger 104 detachably connected to a central region 106 thereof. For example, the hanger 104 can be threadably secured to the base 102. The base 102 includes a top open end 108 to form an annular-shaped trough 110, as best seen in FIGS. 7-9, for containing nectar feed 112.

[0032] A cover 114 is releasably secured to the base 102 at its top open end 108 to cover the trough 110 and protect the nectar feed 112 contained therein. A number of feed ports 116 are provided through the cover 114 to permit access to the nectar feed by the appropriate birds, such as hummingbird, orioles and butterflies, for example. The feed ports 116 are preferably configured to appear as flowers, or other structures, to further attract birds to the feeder 100. Further, the cover 114 can be of different colors, such as red, to attract the desired type of bird. As can be understood, the feed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com