Formwork early-removal construction method allowing three-dimensional space size to be adjustable

A technology of three-dimensional space and construction method, which is applied to formwork/formwork/work frame, on-site preparation of building components, pillars, etc. The height and other problems of the support can not be solved, so as to achieve the effect of saving one-time investment, reducing the amount of formwork configuration, and convenient and flexible construction operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

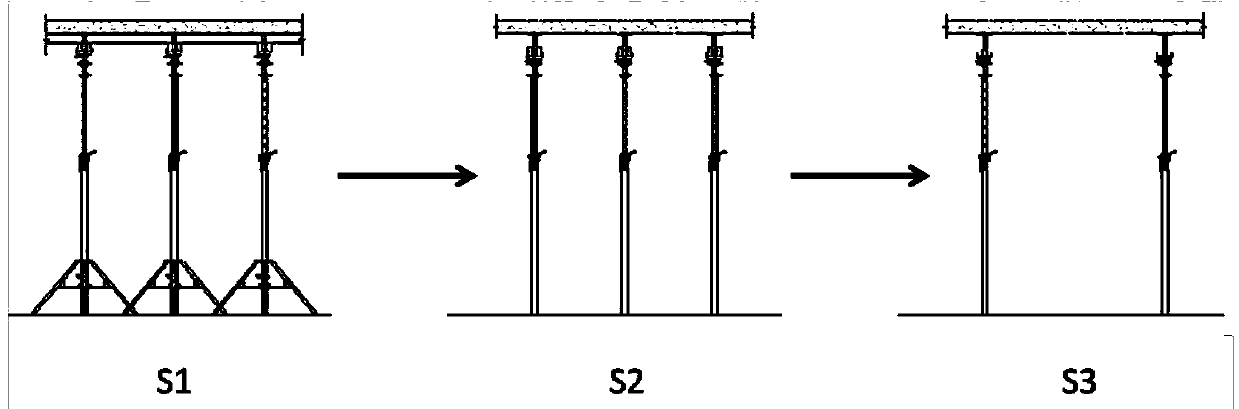

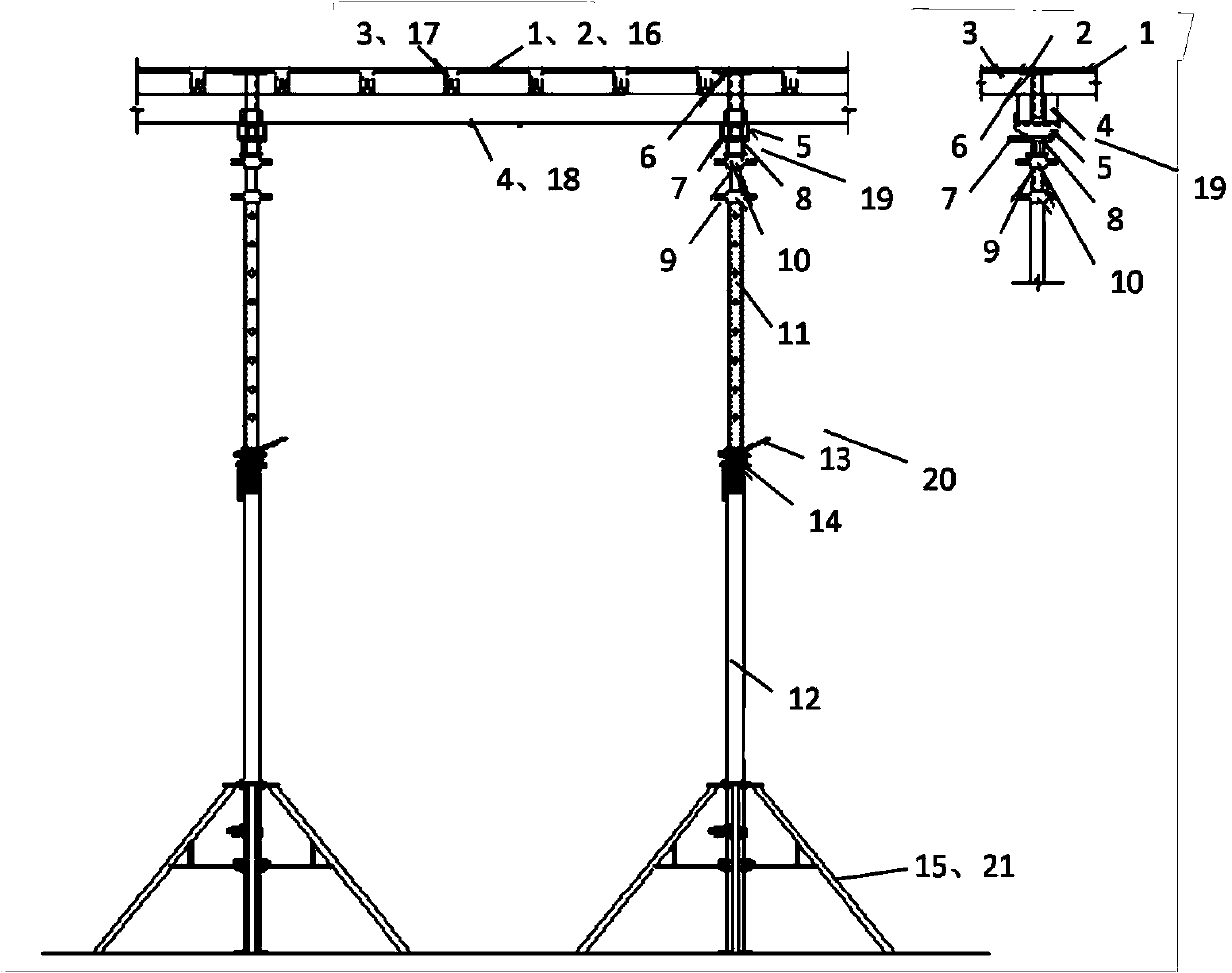

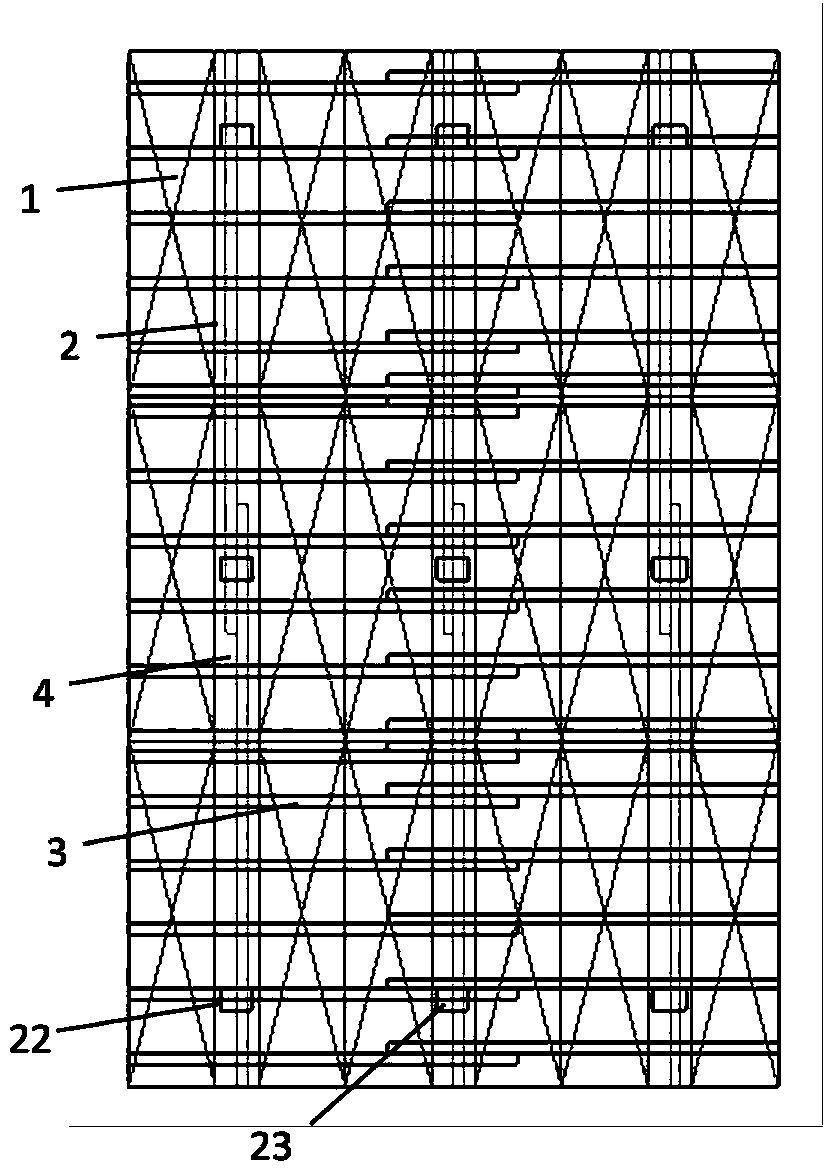

[0037] Example figure 1 with 4 As shown, a formwork early demolition construction method with adjustable three-dimensional space size includes the following steps:

[0038] S1 early demolition support system installation:

[0039] The length and width of the S1-1 early demolition support system are adjusted by overlapping the main beam 4 and the secondary beam 3. The height is adjusted by the expansion and contraction of the inner tube 11 and the outer tube 12, locked with the positioning pin 13, and then fine-tuned with the nut 14 Finish;

[0040] S1-2 Bind the floor steel bars for the early demolition support system, and pre-embed the water and electricity pipelines and embedded parts;

[0041] S1-3 Concrete the floor slab for the early demolition support system, and remove the tripod 15;

[0042] S2 template removal:

[0043] S2-1 Carry out maintenance for the concrete poured on the floor slab. When the design concrete strength grade value is ≥50%, start to dismantle the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com