Corbel type elevator shaft integral lifting operation platform

An overall lifting and operating platform technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems that the bolt torque is difficult to reach the required value, the fastening bolt torque is insufficient, and the scaffolding is placed unstable. Achieve the effect of strong bearing capacity, stable structure and avoid movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

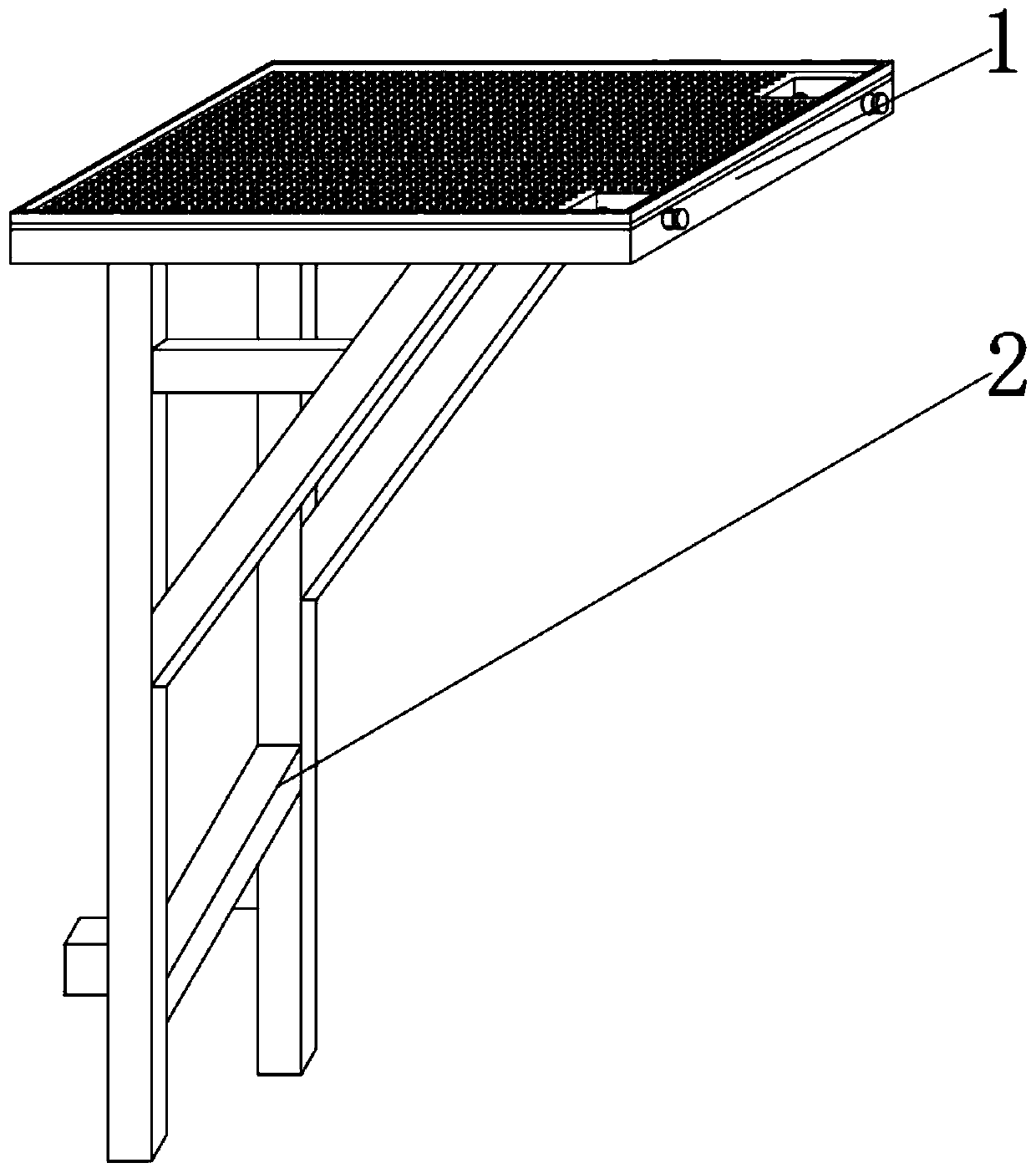

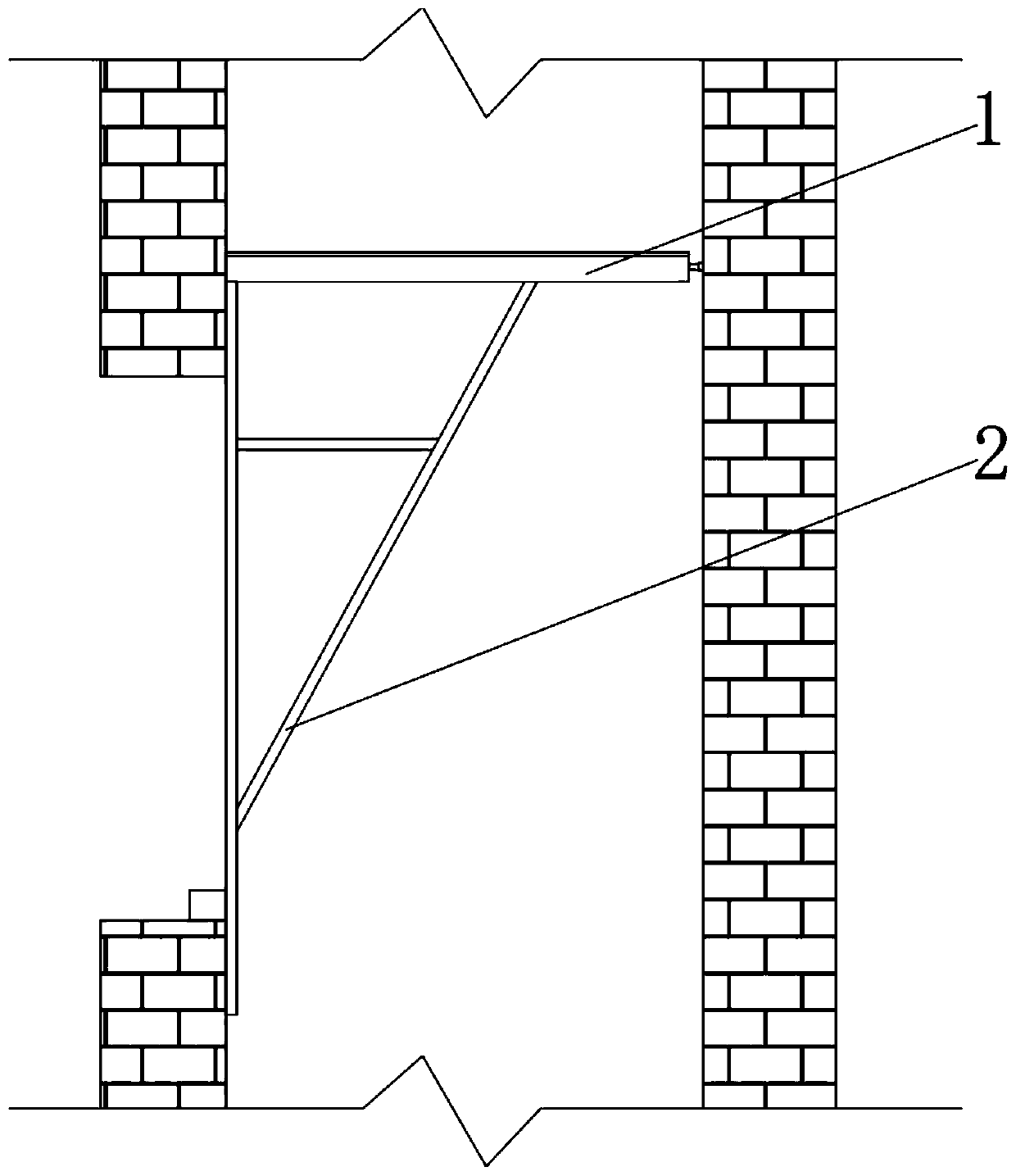

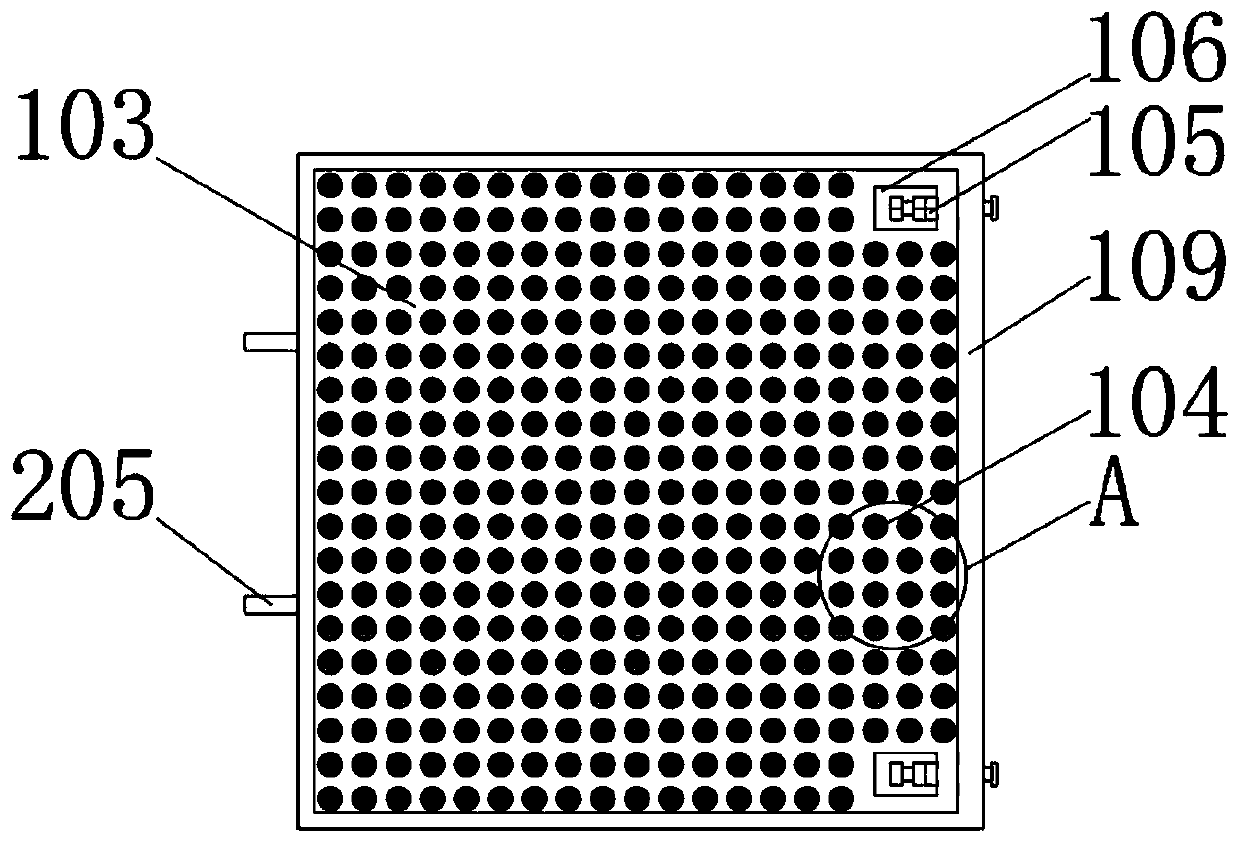

[0035] Refer to attached Figure 1-8As shown, the platform assembly 1, wherein, the platform assembly 1 includes a platform frame 101, a load-bearing bar 102, a surface layer 103, a bump 104, an adjustment device 105 and a rib 109, and the load-bearing bar 102 is welded to the platform frame 101, the surface layer 103 is welded to the top of the platform frame 101, the surface layer 103 is used for construction personnel to carry out construction work on the operating platform, and the bumps 104 and the ribs 109 are arranged from the inside to the outside Installed on the top of the surface layer 103 in turn, the bumps 104 are used to enhance the friction of the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com