Compound pre-mixed feed for chicken

A technology of compounding premix and premix, which is applied in the application, animal feed, animal feed and other directions to achieve the effects of environmental protection, good absorption and feces cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: when described premix is applicable to the 1% premix before breeder breeds, every kilogram of premix contains VitA 390g, Vit D 3 1.65, Vit E 1.2g, Vit K 3 0.055g, Vit B 1 0.045g, Vit B 2 0.150g, VitB 6 0.08g, Vit B 12 0.00027g, pantothenic acid 1.1g, niacin 4.0g, folic acid 0.12g, biotin 0.010g, choline chloride 35.0g, ferrous sulfate heptahydrate 34g, zinc sulfate heptahydrate 48g, copper sulfate pentahydrate 1g, sulfuric acid pentahydrate 43g of manganese, 0.12g of potassium iodide, 0.03g of sodium selenite, and the rest are corn gluten powder and stone powder.

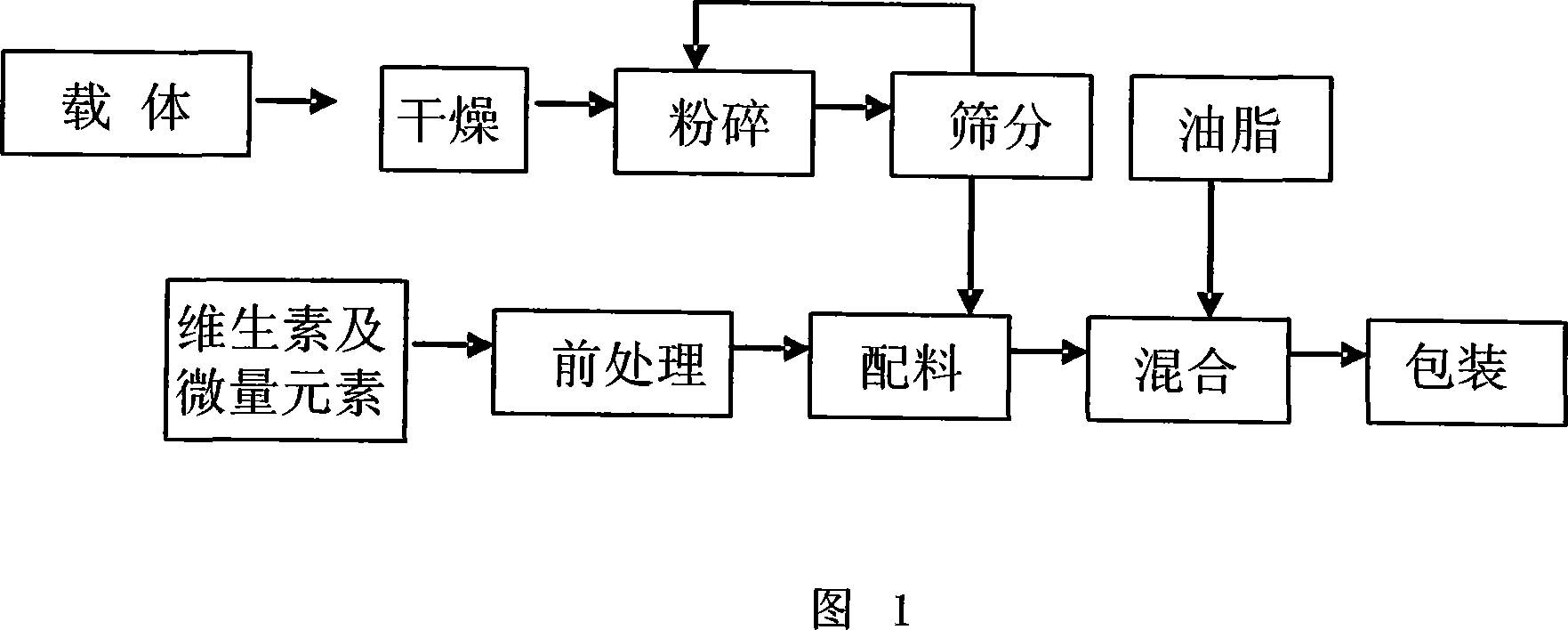

[0023] Above-mentioned proportioning is made the pre-breeding chicken premix (technological process as shown in Figure 1) by following process:

[0024](1) Grinding and sieving the components such as multivitamins and inorganic salts in the proportioning ratio, so that the sieved particle size reaches 30-80 mesh, and the particle size of trace elements reaches below 25 mesh;

[002...

Embodiment 2

[0030] Embodiment 2: when described premix is applicable to the 1% premix of laying chicken, every kilogram of premix contains Vit A 450g, Vit D 3 1.75g, Vit E 1.2g, Vit K 3 0.055g, Vit B 1 0.045g, Vit B 2 0.15g, Vit B 6 0.08g, Vit B 12 0.00027g, pantothenic acid 1.5g, niacin 4.2g, folic acid 0.18g, biotin 0.013g, choline chloride 45g, ferrous sulfate heptahydrate 35g, zinc sulfate heptahydrate 48g, copper sulfate pentahydrate 1g, manganese sulfate pentahydrate 52g, potassium iodide 0.13g, sodium selenite 0.03g, and the rest are corn gluten powder and stone powder.

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0032] Embodiment 3: when described premix is applicable to the 5% premix of breeder before kind, every kilogram of premix contains Vit A66g, Vit D 3 7.5g, Vit E 3g, Vit K 3 0.3g, Vit B 1 0.2g, Vit B 2 0.8g, Vit B 6 0.35g, VitB 12 0.0012g, pantothenic acid 0.29g, niacin 1.36g, folic acid 0.022g, biotin 0.008g, choline chloride 15g, ferrous sulfate heptahydrate 6.5g, zinc sulfate heptahydrate 6.6g, copper sulfate pentahydrate 0.3g, pentahydrate Manganese sulfate water 8g, potassium iodide 0.02g, sodium selenite 0.007g, DL-methionine 22g, calcium 165g, total phosphorus 61.2g, salt 60g, the rest is bran and stone powder.

[0033] The preparation method is the same as in Example 1, except that the carrier corn gluten powder is replaced by bran, and the addition ratio of the premix is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com