Stirrer for desulphurization of molten iron

A technology of molten iron desulfurization and agitator, which is applied in the field of agitators, can solve the problems such as being unfavorable for being involved in the discharge of desulfurization slag, high eddy current intensity at the lower part of the back iron surface of the stirring blade, and deterioration of the dynamic conditions of stirring and desulfurization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

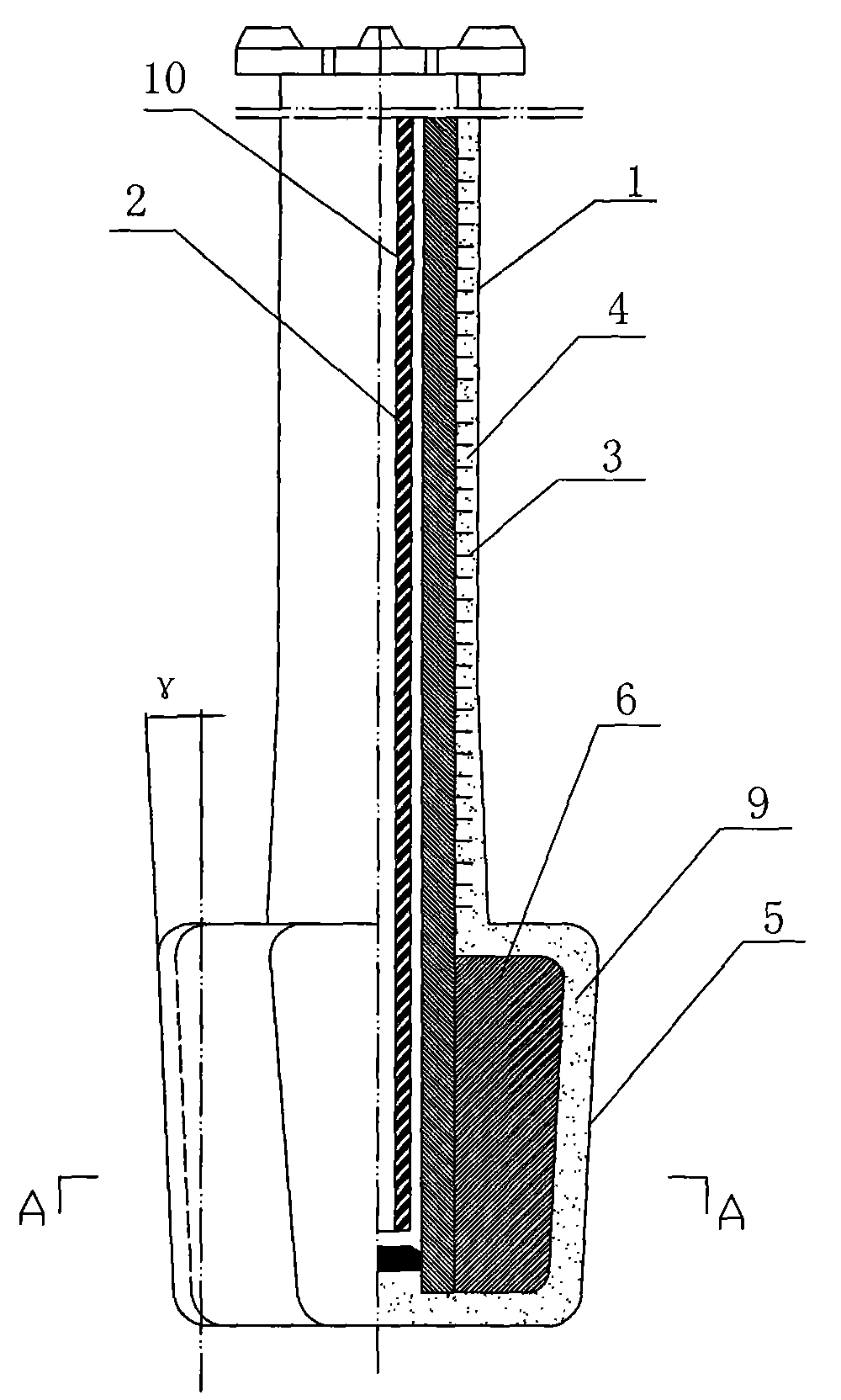

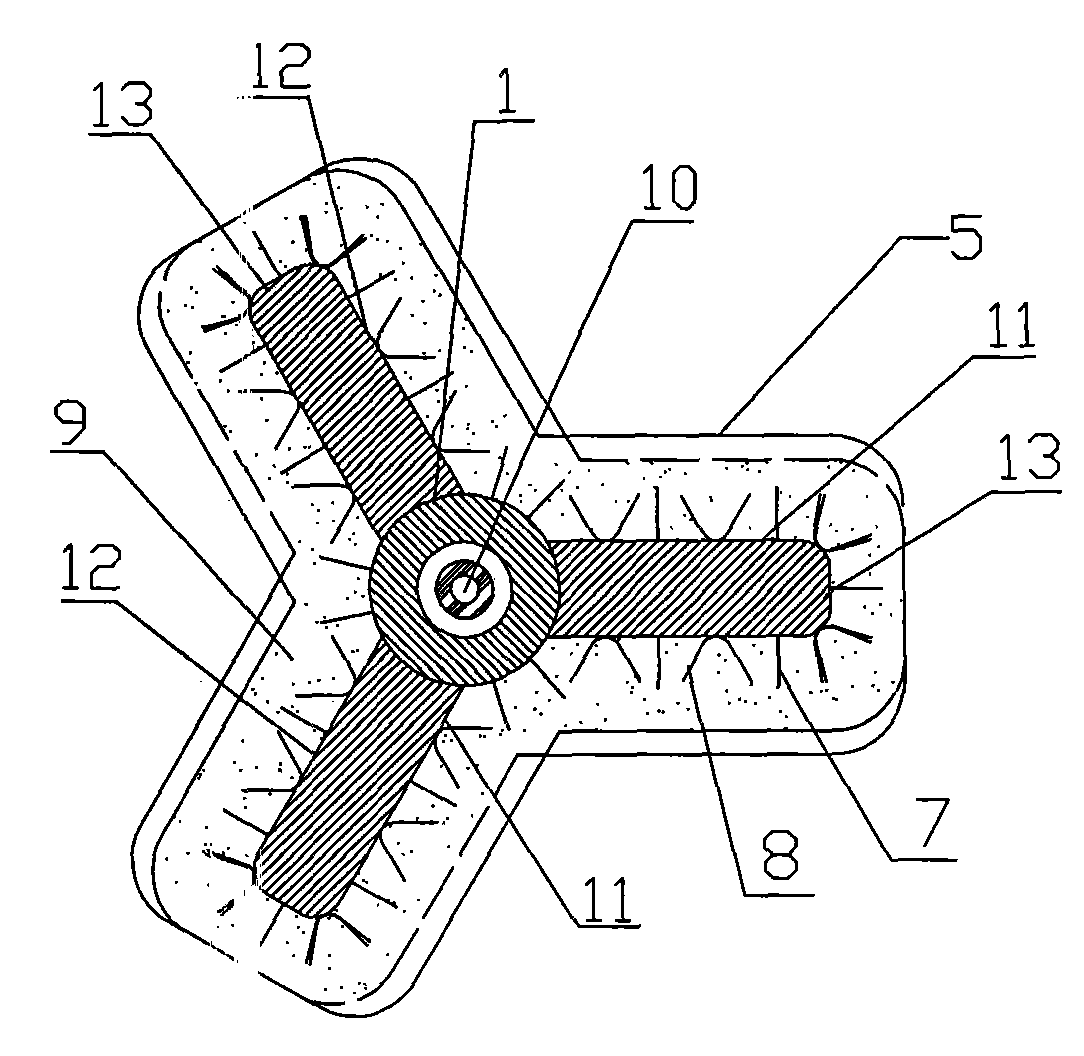

[0012] Describe in further detail below in conjunction with accompanying drawing:

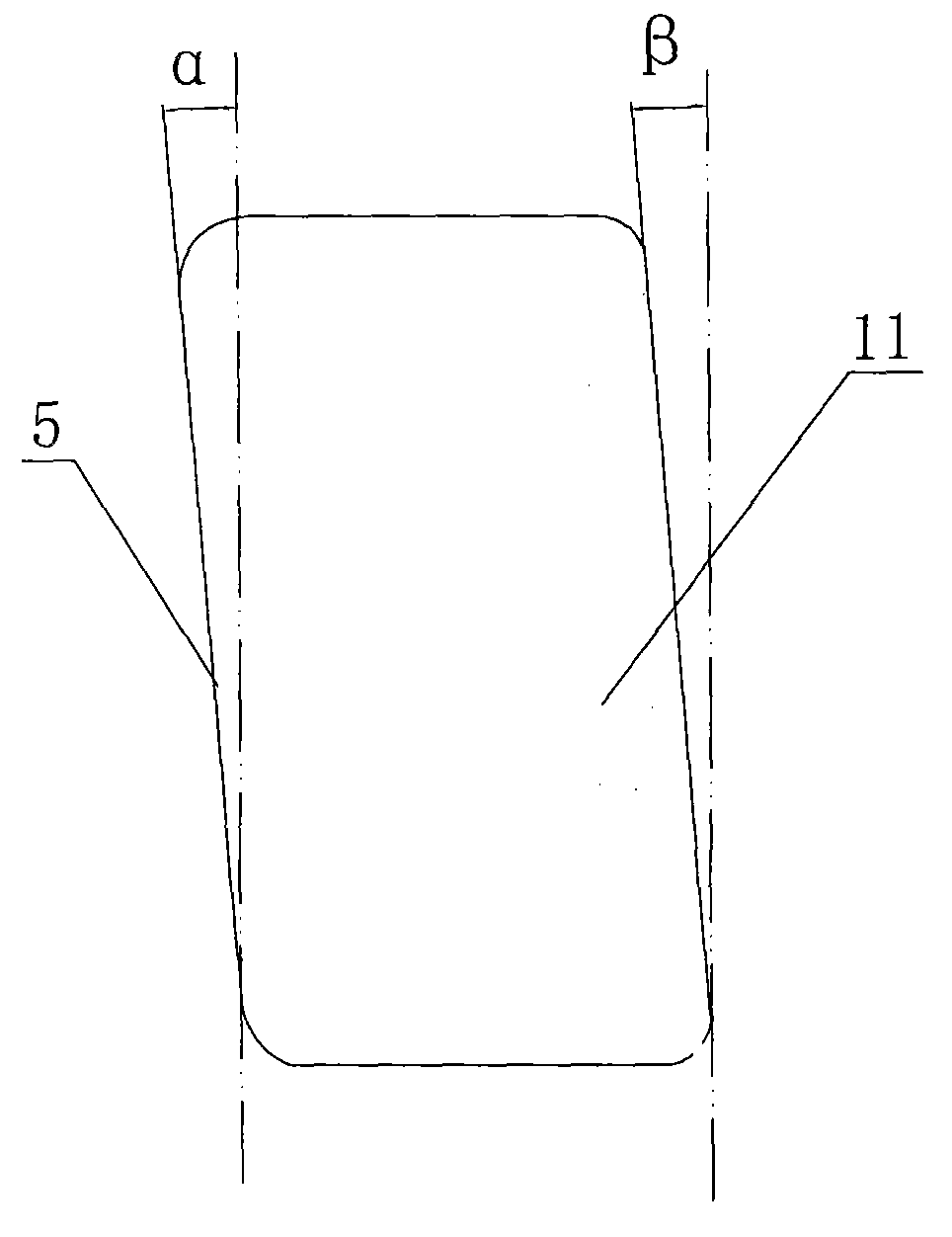

[0013] A new type of stirring head for molten iron desulfurization, which consists of a metal core 2 forming a rotating shaft 1, a V-shaped rivet 3, a refractory lining 4, and a metal chip 6 forming a stirring blade 5, a V-shaped rivet 7, and double V-shaped rivets 8. Composed of refractory lining 9 and air-cooled pipe 10. The stirring blade 5 consists of three pieces.

[0014] In the following embodiments, the air-cooled pipe 10 is made of No. 15 seamless steel pipe; the metal core 2 is made of 20CrMo or 30CrMo thick-walled cast steel pipe; V-shaped rivets 3, V-shaped rivets 7 and double V-shaped rivets 8 The height is 1 / 2 to 2 / 3 of the thickness of the refractory working lining. Among them, the V-shaped riveting member 3 is made of ordinary wire rod with a diameter of 8mm, and the V-shaped riveting member 7 is made of outer rib steel bar with a diameter of 10mm, double V-shaped rivets 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com