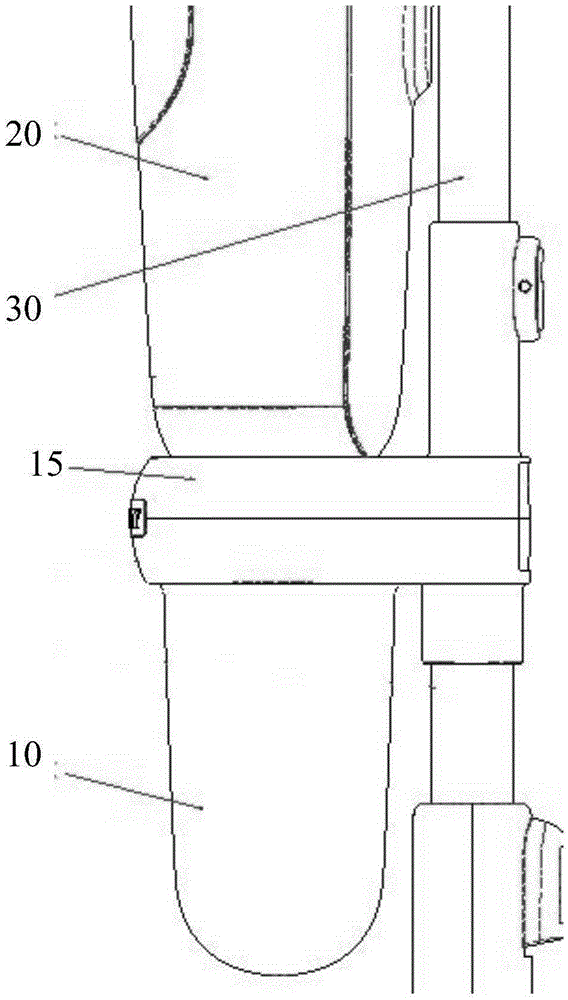

Three-stage tornado dust cup filtering system and dust collector comprising same

A filter system and tornado technology, applied in the direction of vacuum cleaners, suction filters, cleaning equipment, etc., can solve the problems of unfavorable separation of fine dust, increase of air volume loss, unfavorable dust separation, etc., and achieve the effect of convenient cleaning, reduced cleaning and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

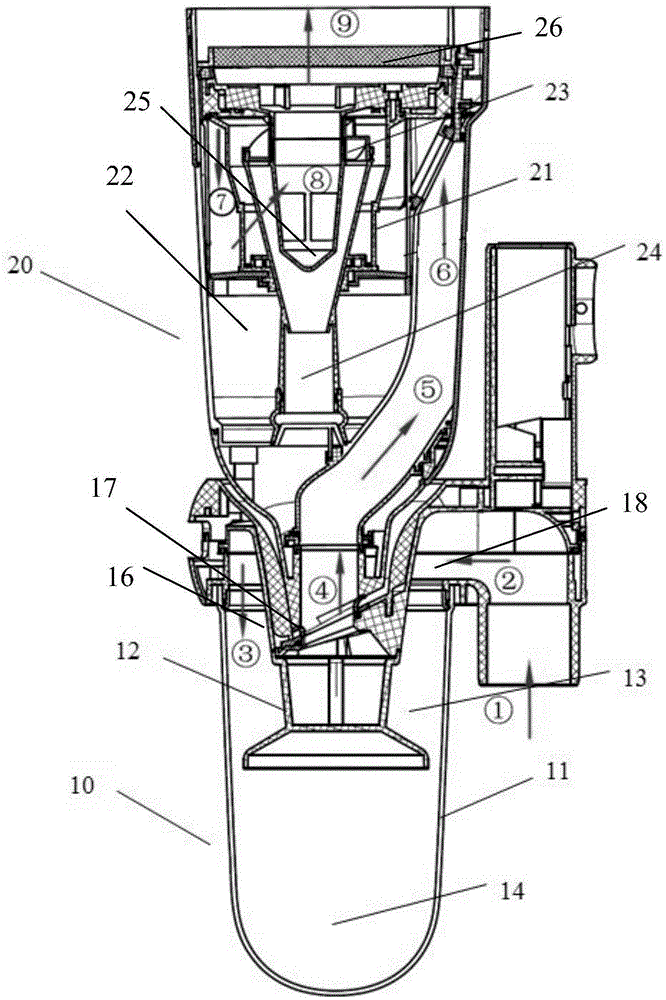

[0028] And in the dust cup filter system of the vacuum cleaner, the dust bag type or a single dust cup tornado filter system is basically used. Dust and hair directly enter the dust cup through the air duct for separation and filtration, so that fine dust and large particles such as hair enter the dust cup together. The first-level tornado structure is not conducive to the separation of fine dust, while the second-level tornado structure is easy for hair to get entangled On the cone, it is not conducive to the separation of dust, and it is also easy to cause the blockage of the Hypa, the loss of air volume increases, and the dust storage capacity of the whole machine is small.

[0029] A secondary dust and gas separation structure and a dust cup containing the structure are disclosed in the prior art (application number: 201510044589.X). This application discloses a secondary dust and gas separation system, but the structure is still in use. There is the above-mentioned techni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com